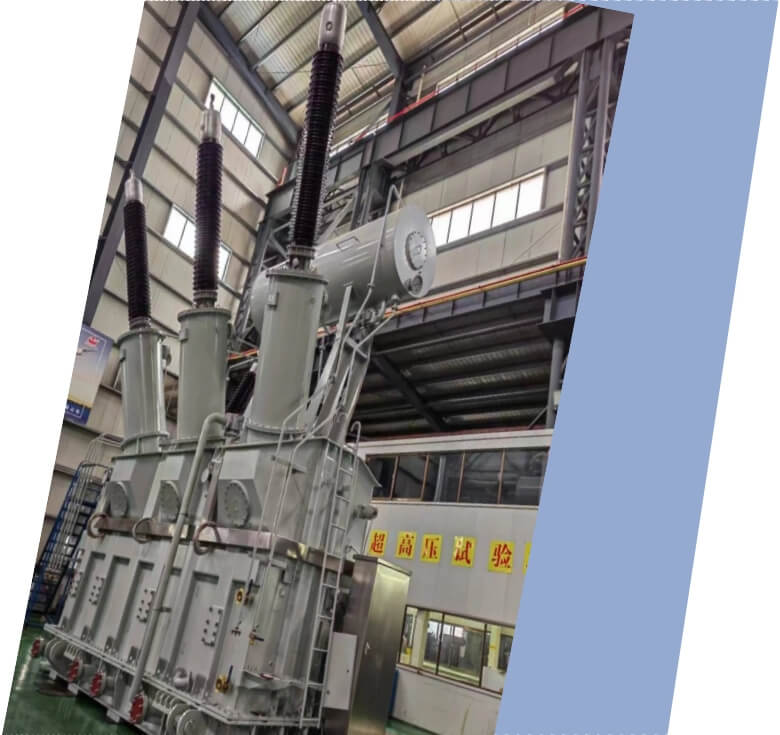

90kV Three-Phase Oil-Immersed Power Transformer

- Primary Voltage Ratings 69kV 66kV 90kV or others

- Secondary Voltage Ratings 33/13.8/11 kV or customized

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL Up to 350kV

- Standards IEEE, ANSI, IEC, CSA

- Application regional substations, large industrial parks, wind/solar farm step-up stations

- Power Rating 75-4000kVA

- Certificate UL ,CESI ,ISO

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 75-4000kVA |

| Rating Primary Voltage | 69kV 66kV 90kV or others |

| Secondary Voltage |

33kV 13.8kV 11kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YNd1, Dyn1, YNd11 or others |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

The transformer body is mounted securely onto a heavy-duty steel base or export-grade wooden pallet. This frame prevents shifting, vibration, and impact damage during transport. Shock absorbers, braces, and structural protectors are placed at all vulnerable points. Multiple protective layers—including moisture-proof barriers, UV-resistant films, rust-preventive coatings, and reinforced corner guards—are applied to ensure full protection in extreme weather or long-distance transportation. Nitrogen-filled sealing can be applied to maintain insulation dryness during sea shipment.

Depending on size and destination, the transformer may be shipped via flat-rack containers, open-top containers, or break-bulk shipment. All packing materials adhere to global ISPM-15 and export regulations. The logistics team coordinates loading, transportation mode selection, customs clearance, and required documentation—including packing lists, test certificates, manuals, quality reports, and installation guides—provided in waterproof envelopes attached to the transformer tank.

Upon arrival on-site, engineering support can be provided for unloading, inspection, reassembly of accessories, oil filling, vacuum filtration, and commissioning. The complete packing and shipping process ensures the transformer reaches the site in perfect mechanical and electrical condition, ready for safe installation and long-term service.

Manufacturer Test

Progress test

The Progress Test for the 90kV Three-Phase Oil-Immersed Power Transformer is conducted throughout the production process to ensure strict quality control and early detection of defects. Raw materials—including copper conductors, silicon steel, insulation paper, and transformer oil—are tested for compliance with technical specifications. During coil winding, inspections verify winding tightness, dimensional accuracy, insulation layering, and conductor integrity. Core assembly is checked for geometric alignment, clamping pressure, and minimal air gaps. Intermediate electrical tests—such as winding resistance, insulation resistance, and partial discharge checks—confirm stability before final assembly. Mechanical components, including the tank and radiators, undergo pressure, leak, and weld integrity tests. Each stage ensures manufacturing consistency and readiness for the final FAT.

Design Tests

All transformers will be tested after finishing the production test items as follows:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Measurement of d. c. Insulation resistance between each winding to earth, and check of the core and frame insulation

♦ Capacitive bushing test

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Measurement of short-circuit impedance and load loss

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

The Factory Acceptance Test for the 90kV Three-Phase Oil-Immersed Power Transformer validates full compliance with international standards and project specifications. Routine electrical tests include winding resistance, turns ratio verification, vector group check, insulation resistance measurement, and polarity confirmation. High-voltage tests—such as applied AC withstand, induced voltage withstand, and partial discharge—ensure dielectric strength. Performance evaluations include no-load loss, load loss, impedance measurement, and temperature-rise testing. Lightning impulse tests verify insulation resilience against overvoltage surges. Mechanical inspections confirm tank tightness, bushing alignment, cooling system function, tap changer operation, and transformer oil quality. All protection devices, including Buchholz relays and temperature controllers, are calibrated and tested. FAT reports are reviewed with the customer before shipment.

Routine Test - Excitation & No-Load Loss (Rated Voltage)

Voltage source: usually rated voltage (such as 230V, 400V, 660V, customized according to equipment requirements)

Temperature and humidity meter: used to record ambient temperature and humidity conditions

Check the device terminals and wiring to ensure that the connection is secure and not loose or contaminated.

Ensure the test environment is suitable: relative humidity below 75%, no rain, and recommended temperature is 20-30°C.

Connect the test equipment to the appropriate terminals of the device under test and ensure that all connection points are properly grounded to avoid current leakage during the test.

Apply Test Voltage:

Select a suitable test voltage according to the rated voltage of the equipment (for example, the rated voltage is 11kV, 33kV or others), and ensure that the applied voltage is stable.

No-load loss

Excitation loss

Power factor

Voltage

Current

Ambient temperature and humidity during testing

No-load loss > rated loss (further inspection or corrective action required)

Application

Technical Advantages

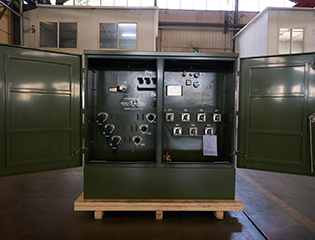

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.