Wires and Cables

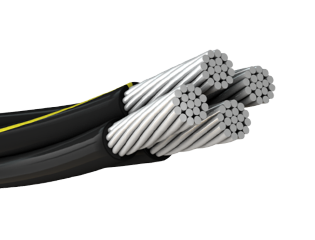

Overhead Insulated Cable

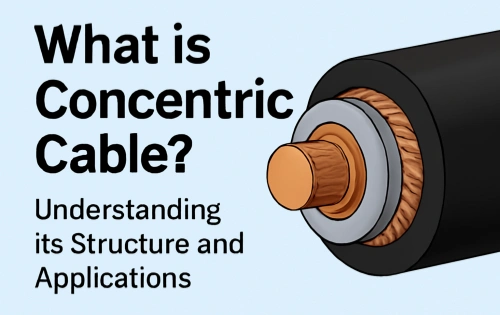

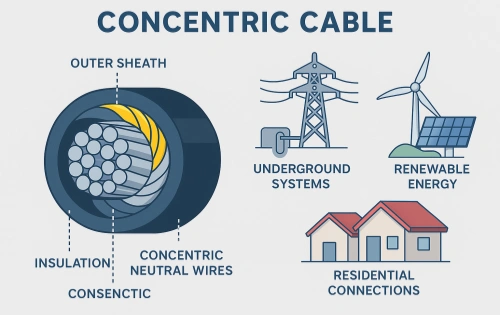

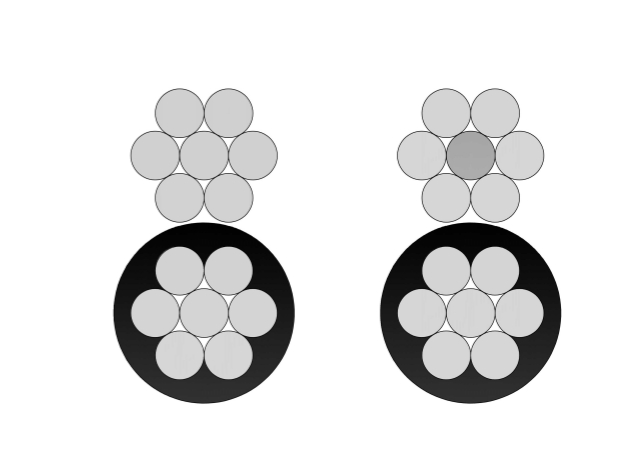

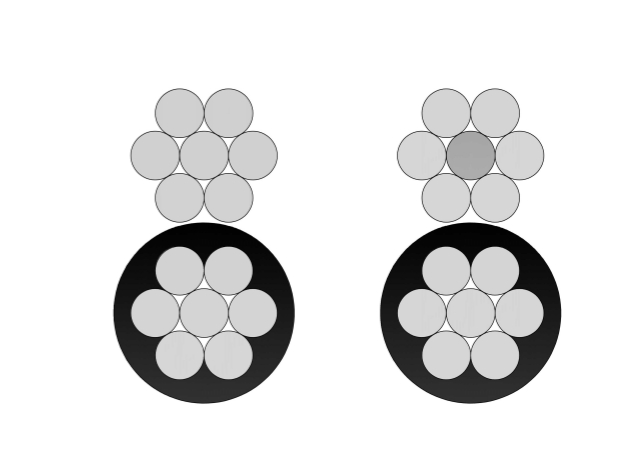

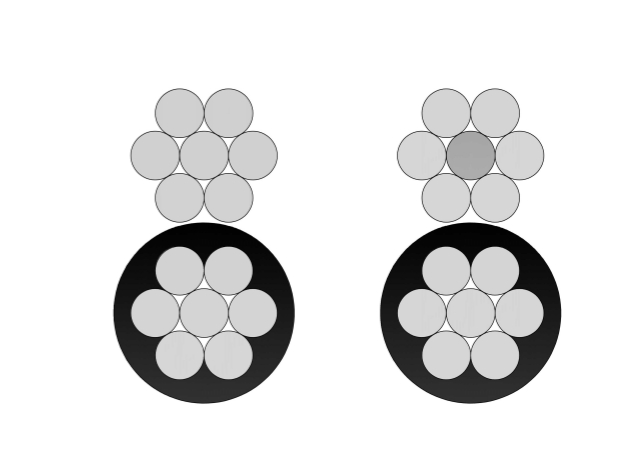

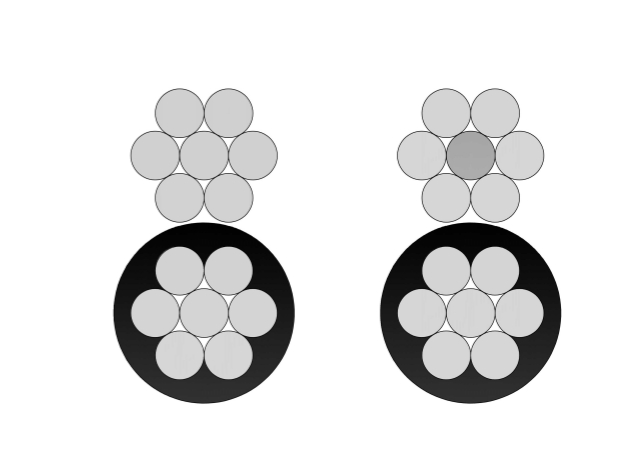

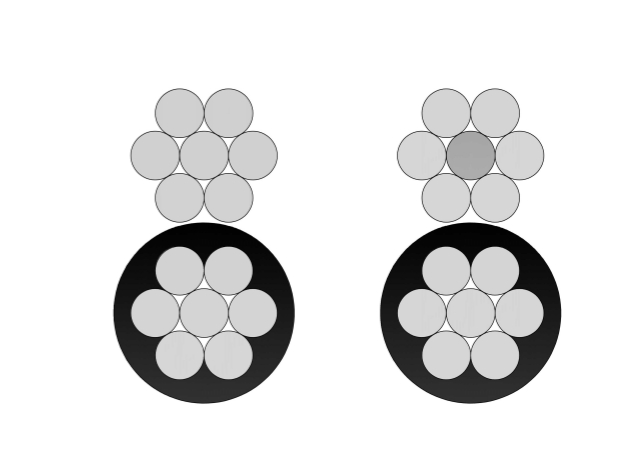

CONCENTRIC CABLE

NPC Electric Concentric Cable is designed with a central phase conductor surrounded by an evenly distributed concentric neutral conductor, providing a stable electrical return path and enhanced system safety. The concentric construction ensures uniform current distribution, reduces electromagnetic interference, and improves grounding reliability. High-purity copper or aluminum conductors are combined with durable insulation materials that offer excellent resistance to moisture, heat, and environmental stress. This cable structure is widely used in low-voltage power distribution, where mechanical protection and electrical stability are critical. The concentric neutral layer also enhances fault current handling and minimizes voltage drop during operation. With strong mechanical strength, long service life, and consistent electrical performance, concentric cables are suitable for underground installation and utility networks requiring dependable power delivery.

ABC CABLE NFC 33-209

Aerial Bundled Cable under NPC 33-209 standard is mainly used in the field of overhead power distribution. ABC Cable, manufactured in accordance with NFC 33-209 is designed for overhead low-voltage power distribution with enhanced mechanical strength and operational safety. The cable consists of insulated aluminum phase conductors twisted around a reinforced messenger conductor, forming a compact aerial bundle. This structure reduces the risk of short circuits caused by external contact and minimizes power outages in densely populated or environmentally challenging areas. The insulation material provides excellent resistance to UV radiation, weather exposure, and thermal aging, ensuring stable electrical performance over long service periods. Compliant with NFC 33-209 requirements, the cable delivers reliable current transmission, reduced line losses, and simplified installation compared with bare conductors. ABC Cable NFC 33-209 is widely used by utility companies for modern overhead distribution networks where safety, durability, and cost efficiency are critical.

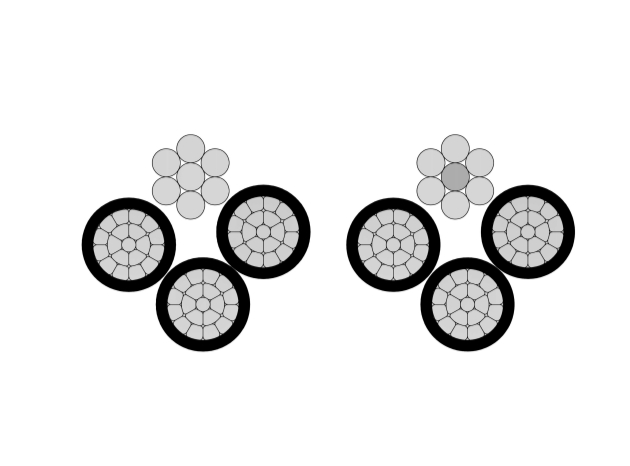

Duplex Service Drop Cable

The Duplex Service Drop Cable is a reliable overhead cable for secondary power distribution from the utility pole to the service entrance. Featuring two insulated phase conductors (aluminum or ACSR) twisted around a bare or covered neutral messenger wire, it offers excellent mechanical strength and weather resistance. Insulation options include XLPE, PE, or PVC for superior UV, moisture, and abrasion protection. Compliant with ASTM B-230, B-231, ICEA S-76-474, and ANSI/ICEA standards, this cable supports low-voltage applications up to 600V. Lightweight design facilitates easy installation with reduced sag and long spans. The Duplex Service Drop Cable ensures minimal power losses, high tensile strength from the messenger, and long service life in harsh outdoor conditions. Ideal for residential, commercial, and rural electrification projects requiring safe, cost-effective aerial service connections worldwide.

Quadruplex Service Drop Cable

NPC Electric Quadruplex Service Drop Cable offers efficient overhead three-phase service with neutral support. Comprising three-phase conductors (aluminum) insulated with XLPE or PE and helically twisted around a strong neutral messenger (ACSR, AAC, or covered aluminum), it meets ASTM, ICEA, and international standards. The messenger provides full self-support, allowing longer spans and reduced infrastructure costs. Premium insulation resists sunlight, moisture, and mechanical abrasion for decades of outdoor service. Lightweight and flexible, it simplifies installation with low sag. The Quadruplex Service Drop Cable ensures minimal losses, high mechanical endurance, and excellent weather performance up to 600V. Flame-retardant options enhance safety. Perfect for reliable power delivery in urban developments, commercial areas, street lighting, and temporary sites requiring safe, cost-effective aerial bundled solutions.

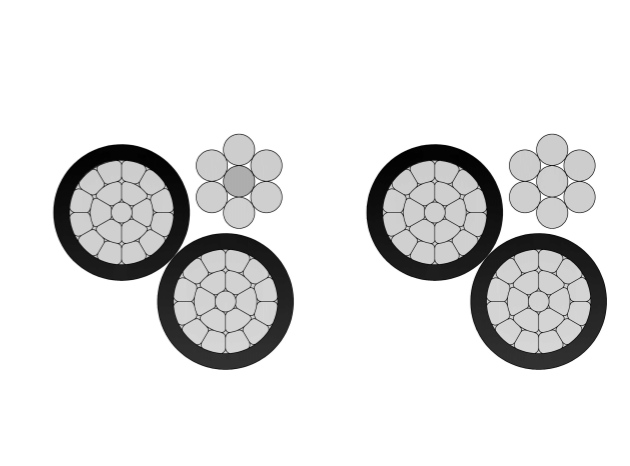

Triplex Service Drop Cable

The Triplex Service Drop Cable is designed for overhead power distribution from utility lines to residential and commercial service entrances. It typically consists of two insulated phase conductors and one bare or insulated neutral messenger conductor, twisted together to provide mechanical support and electrical reliability. The phase conductors are insulated with weather-resistant materials such as XLPE or PE, offering excellent resistance to UV radiation, moisture, and environmental aging. Engineered for dependable performance, the Triplex Service Drop Cable ensures stable power delivery while minimizing line losses and installation complexity. Its lightweight yet robust construction allows for easy stringing across poles and buildings, while maintaining adequate tensile strength for long-span applications. Manufactured in accordance with applicable utility and industry standards, this cable is widely used in low-voltage overhead distribution networks where safety, durability, and long service life are essential.

1/0 Bull Aluminum Conductor Duplex Overhead Service Drop Cable

1/0 Bull Aluminum Conductor Duplex Overhead Service Drop Cable is designed for reliable secondary overhead power distribution from utility lines to residential and commercial service entrances. The cable consists of two aluminum conductors, typically one phase conductor and one neutral messenger, stranded concentrically to provide flexibility, strength, and stable electrical performance. The 1/0 Bull size offers a balanced combination of current-carrying capacity and mechanical durability, making it suitable for short- to medium-span service drop installations. Aluminum conductors ensure lightweight handling, reduced installation effort, and excellent corrosion resistance in outdoor environments. Manufactured in accordance with relevant ASTM and utility standards, the 1/0 Bull Aluminum Conductor Duplex Overhead Service Drop Cable delivers consistent conductivity, controlled sag, and dependable long-term operation. It is widely used by utilities and contractors seeking a cost-effective, easy-to-install solution for overhead service connections.

1/0 Malemute Aluminum Conductor Duplex Overhead Service Drop Cable

1/0 Malamute Aluminum Conductor Duplex Overhead Service Drop Cable is designed to deliver efficient and reliable power in overhead secondary distribution networks. Constructed with stranded aluminum conductors, the duplex configuration provides a combination of electrical conductivity, mechanical strength, and installation flexibility. The 1/0 Malamute size is suitable for typical service drop spans, offering dependable load capacity with controlled sag under varying weather conditions. Aluminum construction reduces overall cable weight, simplifies handling, and enhances corrosion resistance for long-term outdoor use. Produced under strict quality management systems, the 1/0 Malamute Aluminum Conductor Duplex Overhead Service Drop Cable meets utility and ASTM standards, making it a trusted solution for modern overhead service installations requiring safety, durability, and consistent performance.

2 Chow Aluminum Conductor Duplex Overhead Service Drop Cable

2 Chow Aluminum Conductor Duplex Overhead Service Drop Cable is designed for dependable secondary overhead power distribution from utility lines to residential and light commercial service entrances. The duplex configuration consists of two stranded aluminum conductors, typically functioning as a phase conductor and a neutral messenger, providing both electrical transmission and mechanical support. The No. 2 Chow conductor size delivers balanced current-carrying capacity with controlled sag, making it suitable for short to medium service drop spans. Aluminum construction offers low weight, excellent corrosion resistance, and ease of installation in outdoor environments. Manufactured in accordance with ASTM and utility specifications, the 2 Chow Aluminum Conductor Duplex Overhead Service Drop Cable ensures uniform stranding, stable conductivity, and reliable long-term performance. It is widely used by utilities and contractors seeking a cost-effective, durable solution for overhead service drop applications.

2 Doberman Aluminum Conductor Duplex Overhead Service Drop Cable

The 2 Doberman Aluminum Conductor Duplex Overhead Service Drop Cable is designed to provide efficient and dependable power delivery in overhead secondary distribution systems. Constructed with stranded aluminum conductors, the duplex configuration combines electrical conductivity with mechanical support for service drop installations. The No. 2 Doberman size is suitable for standard service drop spans, offering reliable load capacity with controlled sag under varying environmental conditions. Aluminum conductors reduce overall cable weight, simplify handling, and enhance corrosion resistance for long-term outdoor operation. Produced under strict quality management systems, the 2 Doberman Aluminum Conductor Duplex Overhead Service Drop Cable meets utility and ASTM requirements, making it a trusted solution for modern overhead service connections where safety, durability, and consistent performance are essential.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, NPC Overhead Insulated Cable exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

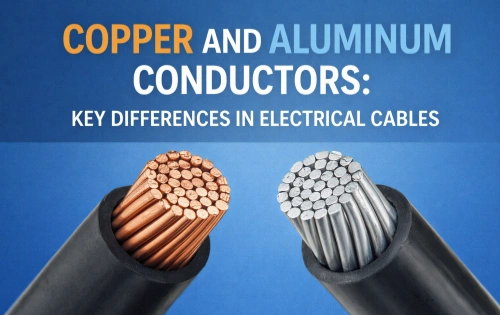

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

NPC Overhead Insulated Cable have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Overhead Insulated Cable Manufacturer

Overhead Insulated Cable Benefits

Overhead Insulated Cable Installation

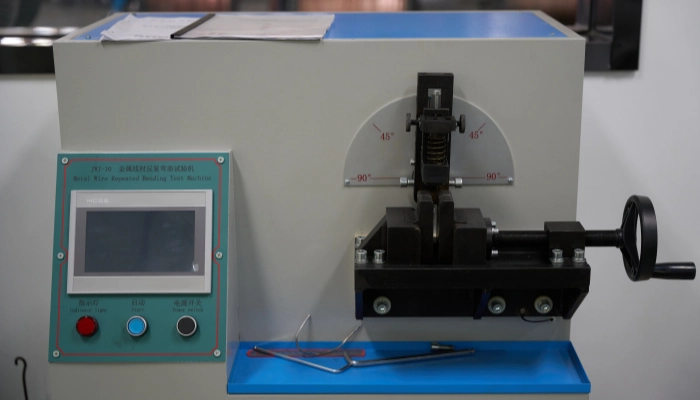

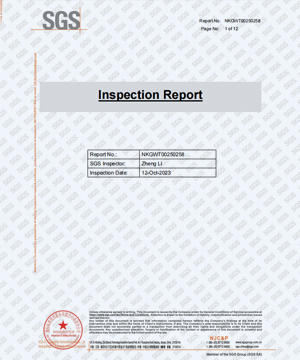

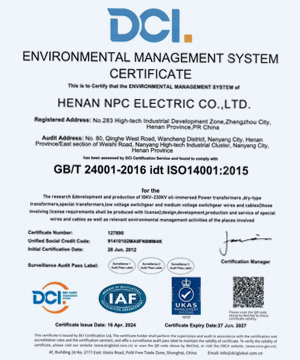

Testing and Certification

Product Show

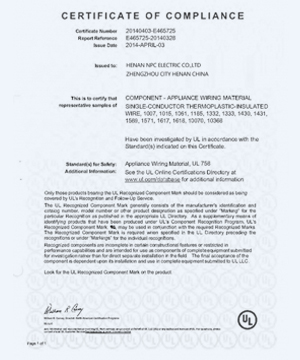

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

UL Product Certificate

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Related Articles

Technical Advantages

FAQ From Customers

-

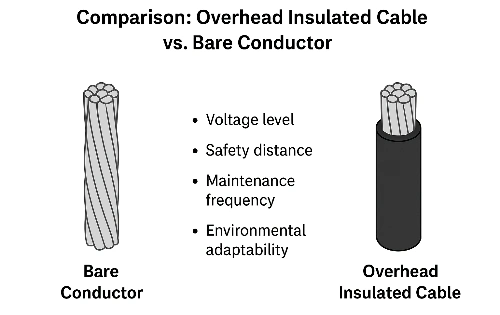

What is the structure of an overhead insulated cable?

Overhead insulated cables typically consist of a conductor, insulation layer, and an optional outer sheath. The conductor is usually made from aluminum or copper, providing excellent electrical conductivity. The insulation layer, made from materials like cross-linked polyethylene (XLPE) or PVC, protects the conductor and prevents accidental contact with live wires. An optional outer sheath is added for additional mechanical protection and durability, particularly in harsh environmental conditions. -

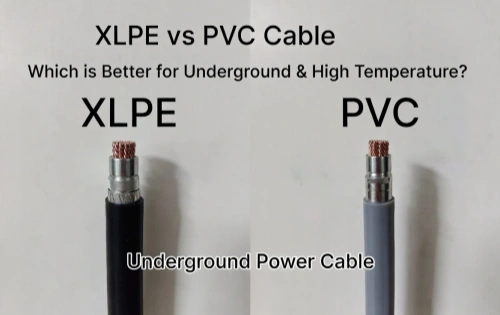

What materials are used for the insulation of overhead insulated cables?

The insulation of overhead insulated cables is typically made from cross-linked polyethylene (XLPE), which offers superior thermal stability, electrical insulation properties, and resistance to environmental factors. Alternatively, PVC (polyvinyl chloride) can be used for lower voltage applications. These materials help prevent electrical hazards by ensuring that the conductor remains safely insulated, especially in outdoor and exposed environments such as overhead power lines. -

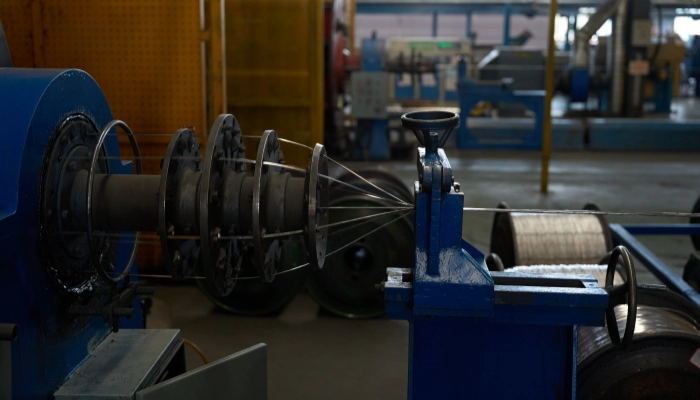

How are overhead insulated cables manufactured?

The manufacturing process of overhead insulated cables begins with the conductor preparation, which involves drawing aluminum or copper to the desired size. The insulation layer is then applied using extrusion technology, ensuring uniform thickness and durability. For high voltage cables, the insulation is cross-linked to improve performance at elevated temperatures and resist electrical stress. The outer sheath is then added, providing protection against physical damage and environmental conditions. The entire process follows stringent quality control and testing procedures to ensure reliability and compliance with international standards such as IEC and ANSI. -

What makes overhead insulated cables suitable for high voltage applications?

Overhead insulated cables are suitable for high voltage applications due to their specialized insulation materials such as cross-linked polyethylene (XLPE), which provides excellent electrical strength and thermal stability. These materials prevent the risk of electrical leakage and offer protection against high voltage surges. The cables' mechanical strength and weather-resistant outer sheath ensure long-term durability and performance, even in extreme environments. Additionally, the insulated layers prevent external damage from wind, moisture, and physical contact, making them ideal for high-voltage power transmission. -

How do overhead insulated cables protect against environmental factors?

Overhead insulated cables are designed to withstand environmental challenges such as moisture, extreme temperatures, UV radiation, and mechanical stress. The insulation material, typically XLPE or PVC, offers excellent resistance to corrosion and weathering, ensuring long-lasting performance even in harsh climates. The outer sheath further protects the cable from abrasion, chemical exposure, and physical damage, ensuring that the cables maintain their integrity and electrical safety during their service life.