1500kVA Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC, UL

- Application Industrial and Power Sectors

- Power Rating 1500kVA

- Certificate UL, CESI, CE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 1500 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 780 kg | |

| Total Weight | 4300 kg | |

| Outline Dimensions(L×W×H)in. | 2550 × 1600 × 2400(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

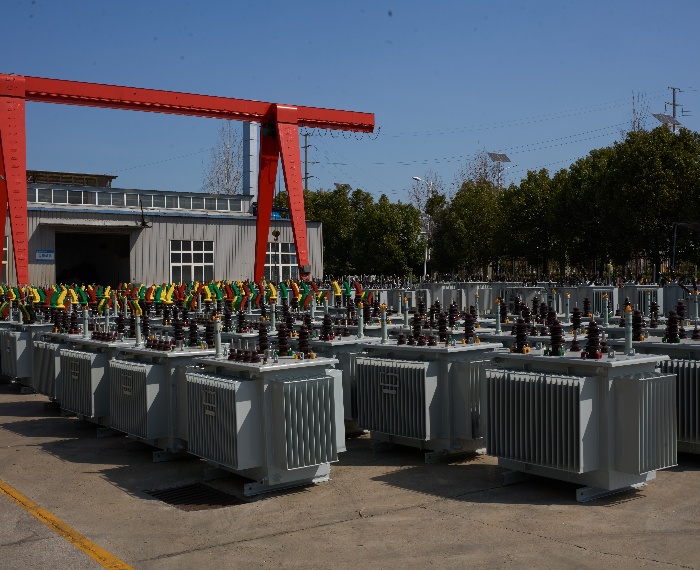

Packing and Shipping

First, the transformer body is fixed on a sturdy wooden pallet to ensure stability during transportation. Then, the key parts of the transformer, such as bushings and oil pillows, are wrapped with shock-proof rubber pads to reduce the impact of vibration on the equipment. The transformer oil is sealed to ensure that there will be no leakage during transportation, and the oil tank part is strictly protected from moisture.

The external packaging is a wooden box or steel frame, which can effectively prevent damage from external forces during transportation. According to the import requirements of the destination country, all necessary export documents, certificates of origin, and compliance certificates will be included with the goods. In terms of transportation methods, sea, rail, or road transportation is selected according to customer needs and destination to ensure safety during transportation.

During the transportation of the transformer, all loading and unloading, and transportation strictly follow professional operating specifications to avoid any unnecessary risks. After arriving at the destination, the transformer will be cleared by customs and handed over to the designated consignee for unloading and installation. All unloading instructions are accompanied by detailed diagrams to ensure that the equipment is installed correctly. In order to ensure the long-term stable operation of the equipment, the transportation process of the transformer is strictly controlled, and professional technical support is provided throughout the process.

Through this series of packaging and transportation processes, NPC ELECTRIC's 1500kVA oil-immersed transformer can reach customers safely and quickly, ensuring that there is no worry during use.

Shipping arrangements are organized according to customer delivery terms and project schedules. The manufacturer collaborates with experienced logistics providers to ensure safe loading, optimized routing, and timely delivery. Complete shipping documentation, including packing lists, inspection reports, and compliance certificates, is prepared to facilitate smooth customs clearance.

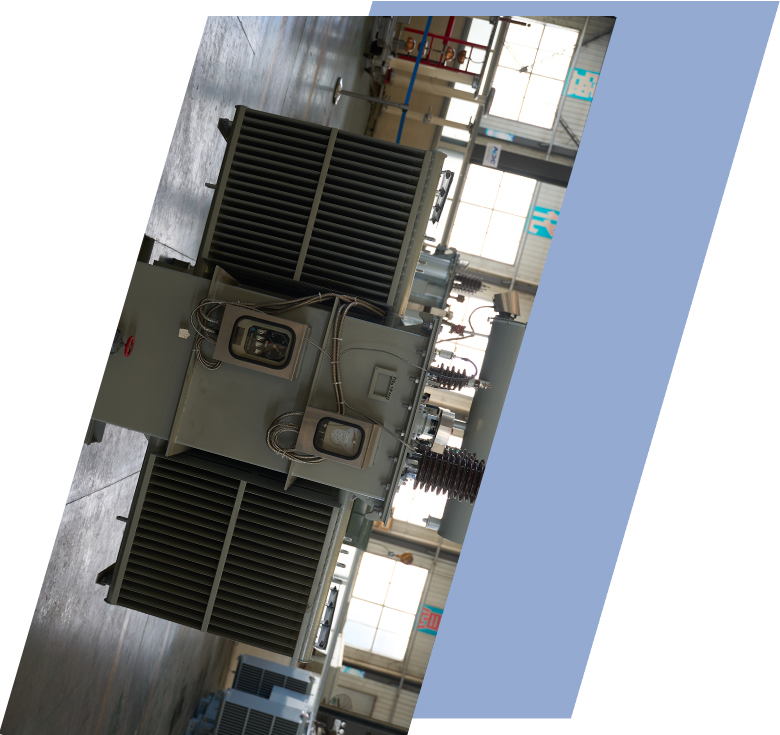

Manufacturer Test

Progress Test

NPC ELECTRIC's 1500kVA oil-immersed transformers are produced with various progress tests strictly in accordance with international standards. First, we conduct a preliminary inspection of the various components of the transformer to ensure that all parts meet the design requirements. Next, we conduct insulation performance tests to ensure that the oil-immersed transformer can operate normally under high-voltage conditions. After that, we conduct temperature rise tests to verify whether the transformer can maintain a safe temperature range when operating at full load. Next, we test short-circuit impedance and load tests to ensure that the electrical performance of the transformer meets the expected standards. All test results meet the design specifications and are recorded as the basis for final quality acceptance. Finally, after rigorous inspection and testing, NPC ELECTRIC's 1500kVA oil-immersed transformers are ready for delivery, ensuring their reliability and efficiency at the customer's site.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

NPC ELECTRIC's 1500kVA oil-immersed transformers undergo a rigorous transformer factory acceptance test (FAT) before leaving the factory. First, all the transformer's electrical parameters, including rated voltage, rated current, and frequency, will be fully tested under special test equipment to ensure that they meet the design requirements. Then, the transformer's insulation performance is tested to confirm that it can withstand the insulation strength at the rated voltage to avoid any electrical faults. In addition, a load test will be carried out to ensure that the transformer can work stably in actual operation without overheating or abnormal current fluctuations. The transformer's oil-immersed system will also be inspected for sealing and oil quality to ensure the cleanliness and safety of the oil. At the same time, vibration tests and noise tests will also be carried out to ensure that the equipment runs smoothly without abnormal noise. Finally, after all tests are passed, a detailed test report will be issued to confirm that the transformer's various performance indicators meet national and international standards. This factory acceptance test lays a solid foundation for ensuring the high quality and safety of the transformer when it is delivered.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.