45kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or Others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, ASTM

- Application EV Charging

- Power Rating 45kVA

- Certificate UL ,CESI ,DNV or SGS

- Cooling Method ONAN,KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 45 kVA |

| Rating Primary Voltage | 11950DELTA |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As NEMA Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 |

| Insulating Oil Weight | 370 kg |

| Total Weight | 1000 kg |

| Outline Dimensions(L×W×H)in. | 50×39×68 |

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

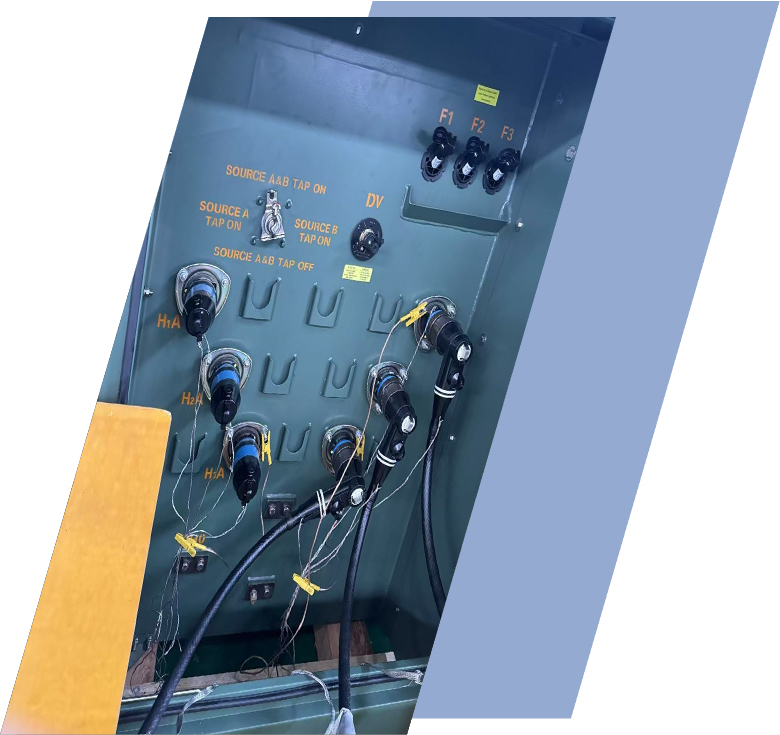

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

For tank and cabinet features, we offer durable stainless steel constructions, including full stainless steel units and customizable service entrances. Additionally, features like copper ground bus bars, Kirk-Key provisions, and a nitrogen blanket enhance reliability and safety.

We also provide special designs for critical applications, seismic environments, and high altitude conditions, ensuring transformers are tailored for specific operational needs. NPC ELECTRIC transformers come with flexible switching options, such as loadbreak switches, visible break systems, and tap changers for efficient load management.

Other options include metering packages, fan systems, and control boxes in various configurations for enhanced monitoring and control. We also offer coatings in ANSI® standard colors and custom decals for safety compliance.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

The sea freight wooden crates are made from high-quality, durable wood, treated to prevent moisture damage, corrosion, and pests. The crate is also reinforced to withstand the rigors of sea transport, offering superior protection from shocks and vibrations.

To enhance safety and security, the transformer is securely mounted inside the crate with anti-shift supports. This prevents any movement during transit, reducing the risk of mechanical damage. Additionally, the crate is equipped with strong, secure fastening systems to keep the transformer in place.

We ensure that all wooden crates are fully compliant with international shipping regulations, including ISPM 15 standards, to prevent any issues with customs and quarantine procedures. This makes our packaging solution both reliable and cost-effective for global shipments.

In addition to robust packaging, we provide comprehensive shipping insurance for every transformer. This insurance covers potential risks during transit, such as damage, theft, or natural disasters. By offering this coverage, we ensure peace of mind for our clients, knowing their valuable equipment is protected throughout its journey.

Whether shipping to overseas projects or international clients, our wooden crate packaging, coupled with shipping insurance, guarantees that your transformer arrives in perfect condition, ready for installation. With careful design and attention to detail, we prioritize the safety, security, and integrity of your equipment throughout the shipping process.

Manufacturer Test

Progress test

NPC Electric manufacture pad mounted transformer have the strict quality control from the raw material stage, Each 75 kVA transformer undergoes a series of routine tests before it leaves the factory, in strict adherence to the ANSI/IEEE C57.12.90 standard. These tests are critical to ensuring the transformer's performance and safety. The routine tests consist of the following:

Ratio tests on each connection.

(b) Polarity verification.

(c) Assessment of no-load losses at 105% rated voltage, corrected to 85°C.

(d) Evaluation of exciting current at 105% rated voltage.

(e) Measurement of load losses and impedance at rated current, conducted on the rated voltage connection, and corrected to 85°C. It's important to note that this test is performed on the high-voltage connection that exhibits the highest measured loss value.

(g) Induced voltage assessments.

(h) Transformer tank leak-detection test, conducted on each transformer tank to validate the integrity of the welds. This test is also performed on the final assembled unit without the pressure relief device.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory acceptance testing for the 45kVA three phase pad mounted transformer opens with comprehensive visual and dimensional inspections against approved drawings, assessing enclosure finish, dead-front integrity, bushing alignment, and compartment security. Winding DC resistance uses Kelvin bridge techniques with temperature correction, results within 0.8% of specified values. Turns ratio and vector group validation across taps employs high-precision TTR for errors under 0.3%. Dissipation factor and capacitance at 10kV limit tan delta below 0.45%. No-load loss and exciting current at rated voltage confirm DOE compliance, excitation capped appropriately. Load loss and impedance quantification via short-circuit method yields accurate efficiency metrics. Power frequency withstand applies required kV for one minute without flashover. Induced voltage test stresses inter-turn insulation. Fluid analysis verifies breakdown voltage exceeding 40kV and low dissolved gases. All test documentation per IEEE C57.12.90, ANSI C57.12.34, and DOE standards includes calibration records, witnessed sign-offs, and resolution of variances before final approval and shipment preparation.

Routine Test - Induced Voltage

AC voltage source, commonly 2 kV, 5 kV, 10 kV, or customized according to test requirements.

Environmental thermometer and hygrometer, used to record the temperature and humidity of the environment for appropriate test evaluation.

Check the connection wires and terminals to ensure they are secure and free of contamination.

Test under suitable environmental conditions: relative humidity below 75%, no rain (recommended temperature: 20-30°C).

Connect the test equipment to the appropriate terminals or bushings of the device under test, ensuring that the connections are secure and properly grounded.

Apply Test Voltage:

Select the appropriate induction voltage according to the rated voltage and standard of the equipment.

Induced Voltage

Applied Current

Voltage peak, stability and waveform (waveform analysis)

Any abnormal current or voltage changes during the measurement process.

1% < Inductive voltage ≤ 3% (Good): still within acceptable range.

Inductive voltage > 3% : faulty or not meet safety requirements and requires further analysis and repair.

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.