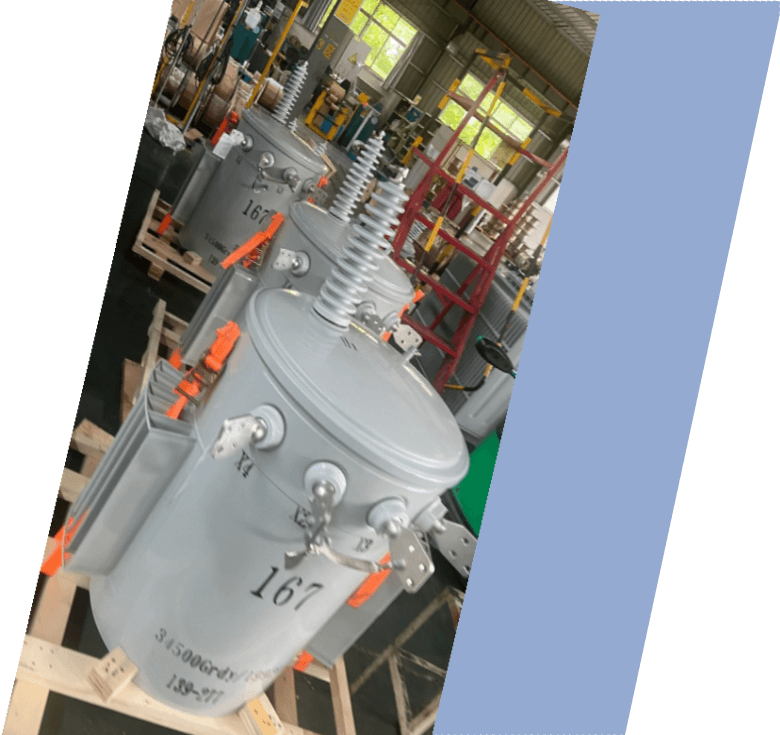

50kVA Completely self-protected(CSP) Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Completely self-protected(CSP) Type

- BIL 30-150kV

- Standards IEEE, ANSI, IEC, CSA, NEMA, UL

- Application Residential, Utility Power Distribution Networks

- Power Rating 50kVA

- Certificate CE, ISO

- Cooling Method ONAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 50 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 62 kg |

| Total Weight | 395 kg |

| Outline Dimensions(W×D×H) | 635×675×1035 (mm) |

| Lifting Lug |

| Tap Changer |

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Support lug |

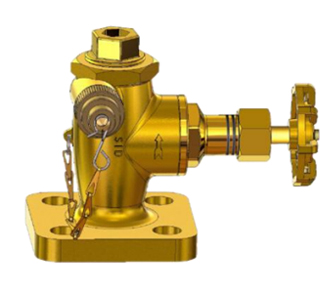

| Oil fill valve |

| Surge arrester |

| Secondary breaker |

| Weak link |

Customization Optional

The optional specifications for the 50kVA Completely Self-Protected (CSP) Single Phase Pole Mounted Transformer offer various customizations to meet specific operational and environmental requirements.

These options include different input voltage levels, such as 11kV or 13.8kV, to align with regional grid standards. Output voltage can be tailored to suit specific needs, typically offering configurations like 230V or 400V.

For installations in harsh environments, optional features like corrosion-resistant coatings, weatherproof enclosures, and advanced insulation materials can be selected to ensure durability and long-term reliability.

These customizable options allow the transformer to be adapted to diverse applications and varying operational conditions, ensuring optimal performance in different settings.

Packing and Shipping

For this purpose, The packing process of the 50kVA CSP single - phase pole - mounted transformer is designed meticulously to safeguard the product from potential damage during transit.

First, the main body of the transformer is tightly sealed with a moisture-proof plastic film. This film acts as a barrier against moisture, preventing rust and damage to the internal electrical components. Subsequently, a layer of soft foam material is used to fully cover the transformer. Special attention is paid to the vulnerable corners and edges, where the foam is thickened to provide enhanced cushioning against impacts.

The wrapped transformer is then placed in a custom-made wooden frame. The dimensions of the frame are precisely tailored to fit the transformer. Inside the frame, there are fixing devices such as straps and slots to firmly hold the transformer in place, effectively preventing it from shifting or shaking during handling and transportation.

On the outer surface of the package, various labels are prominently affixed. Operational labels like "This Side Up", "Fragile", and "Keep Dry" are included to guide the handling personnel. Additionally, information labels indicating the product name, specification model, weight, and dimensions are also provided for easy identification.

Based on the transportation distance and road conditions, an appropriate transportation vehicle is chosen. For long-distance transportation, a professional large-scale freight truck with good shock-absorbing performance is preferred to minimize the impact of bumps during the journey.

The packed transformer is carefully placed on the transportation vehicle. Ropes, steel bands, and other fixing materials are used to securely fasten the transformer to the vehicle. This prevents the transformer from sliding or colliding due to braking, turning, or other maneuvers during driving. Moreover, additional cushioning materials are placed around the transformer to further enhance the protective effect.

During the shipping process, a GPS positioning system is employed to monitor the location and driving status of the transportation vehicle in real-time. This enables timely tracking of the transportation progress and prompt response to any emergencies. In addition, vibration sensors can be installed to monitor the vibration conditions during transportation. If the vibration exceeds the set threshold, immediate measures can be taken.

Manufacturer Test

Progress Test

NPC Electric manufactures pad-mounted transformers have the strict quality control. The progress test for the 50kVA Completely Self-Protected (CSP) Single Phase Pole Mounted Transformer is a series of checks conducted during the manufacturing process to ensure that the transformer meets all technical specifications and safety standards. The test verifies the proper functioning of key electrical parameters, including input and output voltage, load performance, and the effectiveness of the built-in protection mechanisms such as overload, short-circuit, and over-voltage protection. Insulation resistance and dielectric strength tests are also carried out to ensure the transformer's electrical integrity. Additionally, the self-protection system is tested to confirm its ability to automatically disconnect the transformer in case of faults. These progress tests help to identify and resolve potential issues early in the production process, ensuring the transformer meets the required standards before proceeding to the final factory acceptance test.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

NPC Electric will have tests made for quality control by the manufacturer on every device or representative samples, or on parts or materials as required, to verify during production that the product meets the design specifications. The factory acceptance test of the 50kVA fully self-protected (CSP) single-phase pole-mounted transformer is designed to ensure that the transformer meets the relevant standards and specifications.The test items cover electrical performance, mechanical performance, and other aspects. The electrical performance test includes a ratio test to confirm the accuracy of the voltage conversion ratio, no-load loss and load loss tests to evaluate its operating efficiency, and insulation resistance tests to detect insulation conditions to ensure safety; in terms of mechanical performance, the structural integrity of the transformer and the firmness of component connections are checked.

Routine Test - Applied Voltage

Voltage source: usually 1 kV, 5 kV, 10 kV, or customized according to customer needs

Temperature and humidity meter: used to record environmental conditions

Check the connection terminals and wiring to ensure that they are not loose or contaminated.

Test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C).

Properly connect the test equipment to the bushings or terminals of the device under test and ensure that all connection points are properly grounded.

Selecting the test voltage:

Select the appropriate applied voltage based on the rated voltage of the equipment.

Measuring leakage current

Applied voltage

Current stability

Any possible voltage fluctuations

The current value exceeded the allowable range and the equipment needs to be inspected or maintained (pending repair)

There was a serious fault or instability and the equipment could not continue to operate (unqualified)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.