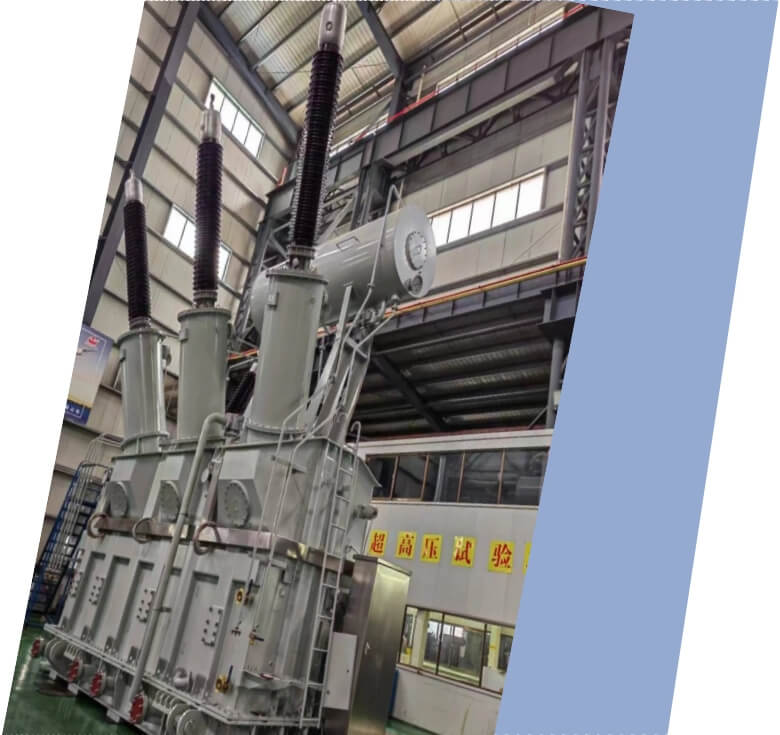

60kV Dyn11/Yyn0 Pure Copper Oil-Immersed Power Transformer

- Primary Voltage Ratings 69kV 66kV 60kV or others

- Secondary Voltage Ratings 33/13.8/11 kV or customized

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL Up to 350kV

- Standards IEEE, ANSI, IEC, CSA

- Application railway electrification, urban compact substations, and heavy industrial parks

- Power Rating 100–5000 kVA

- Certificate UL ,CESI ,ISO

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 100 - 5000kVA |

| Rating Primary Voltage | 69kV 66kV 60kV or others |

| Secondary Voltage |

33kV 13.8kV 11kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YNd1, Dyn1, YNd11 or others |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

All 60 kV porcelain bushings, neutral bushing, conservator, detachable radiator banks, OLTC drive mechanism, cooling fans, Buchholz relay, oil level gauges, temperature indicators, sudden pressure relay, and marshalling box are professionally dismantled and individually packed in custom IPPC-fumigated marine-plywood crates lined with ≥60 mm high-density anti-shock foam and 300 kg of colour-indicating silica-gel desiccant. Each crate carries four 3-axis shock recorders (±250 g) and two electronic tilt watches. The main tank (gross weight 22–45 tons depending on capacity) is welded onto a DNV 2.7-1 certified heavy-lift steel skid with 16 lashing points. The entire body is enclosed in a fully sealed composite crate of 28 mm marine plywood reinforced with 100×100 mm galvanised steel framing, then triple-wrapped with aluminium-foil vapour barrier and heavy-duty heat-sealed tarpaulin. Ten high-resolution impact recorders and real-time GPS/4G monitoring devices are attached.

Inland transport utilises hydraulic modular trailers or low-bed trailers with police escort (total height controlled ≤4.8 m). Sea freight is executed as break-bulk cargo under deck or on 40 ft/80 ft heavy-duty flat-rack containers with CCS/DNV-GL pre-approved lashing plans using Φ28–Φ32 mm steel wire ropes and 80-ton turnbuckles. Full documentation package includes detailed packing list, IPPC fumigation certificate, certificate of origin (Form A/E), nitrogen pressure & trend report, shock recorder baseline data, 110 % all-risk marine insurance (ICC A), third-party loading survey report, and complete installation & commissioning manual. These uncompromising procedures ensure every 60kV Dyn11/Yyn0 Pure Copper Oil-Immersed Power Transformer arrives at any global destination in perfect, immediately energizable condition with zero damage and full traceability.

Manufacturer Test

Progress test

The 60kV transformer undergoes comprehensive, client-witnessable Progress Tests at every critical manufacturing stage to ensure flawless quality before final FAT. Stage 1 (Active Part): individual coil insulation resistance and PI ≥ 2.8, HV/LV winding DC resistance at all taps, core insulation and grounding current <80 mA, preliminary no-load loss and magnetizing current measurement, turns ratio on sample coils, and embedded fiber-optic sensor calibration. Stage 2 (Pre-Tanking): complete voltage ratio test at all tap positions (tolerance ≤ ±0.5 %), vector group Dyn11 or Yyn0 verification, polarity, zero-sequence impedance, magnetic balance, and low-voltage recurrent surge test to detect turn-to-turn faults. Stage 3 (After Vapor-Phase Drying & Vacuum Oil Filling): 48-hour stabilization monitoring, final insulation resistance >18,000 MΩ, tanδ ≤ 0.0035 (20 °C), partial discharge <8 pC at 1.5 μm/√3, oil BDV ≥75 kV/2.5 mm, moisture ≤7 ppm, and full DGA baseline with total combustible gas <0.08 %.

Design Tests

All transformers will be tested after finishing the production test items as follows:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Capacitive bushing test

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

FAT is conducted strictly according to IEC 60076-1/3/5/11 with full client or third-party (SGS/BV/KEMA) witness and officially signed protocol. Tests comprise: winding resistance at all taps corrected to 75 °C; voltage ratio, polarity and phase displacement at principal/extreme taps (≤ ±0.5 %); vector group Dyn11/Yyn0 and magnetic balance confirmation; no-load loss and current at 90 %, 100 %, 110 % rated voltage; load loss and impedance at 75 °C/rated current; separate-source applied voltage withstand; induced overvoltage withstand with PD measurement (<10 pC at 1.5Um/√3, <5 pC at Um/√3); full-wave lightning impulse 275–325 kV peak on 60 kV side; insulation resistance, PI ≥ 2.8, tanδ ≤ 0.0035, oil BDV ≥ 75 kV; temperature-rise test (when specified); OLTC full operation with 10 load cycles + 100 auxiliary cycles; functional verification of cooling stages, Buchholz relay, sudden pressure relay, fiber-optic temperature system, and SCADA interface; sound level measurement (<60 dB); final visual inspection, painting quality, nameplate accuracy, and nitrogen pressure check. The transformer is only released for packing after the client's signature, guaranteeing 100 % readiness for immediate energization and long-term reliable service in 60 kV networks worldwide.

Routine Test - Test of transformer oil

Dissolved Gas Analyzer (DGA): Detects gases in the oil that indicate internal faults.

Acid Value Tester: Determines the oil's acidity to check for oxidation.

Prepare oil sampling kits, testing instruments (e.g., dielectric strength tester, gas analyzer), and clean containers for oil samples.

Ensure all personnel are equipped with necessary safety gear, such as gloves, goggles, and protective clothing.

Visually inspect the oil for signs of contamination or abnormal color before collecting samples.

Carefully extract oil samples from the transformer at specific locations (such as the oil conservator or top of the tank) to ensure accurate representation of the oil’s condition.

Chemical and Gas Analysis:

The pressure is maintained for a set period (usually 30-60 minutes) to observe if there is any drop in pressure, which could indicate a leak.

ASTM D1816 Dielectric Breakdown Voltage of Insulating Liquids

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.