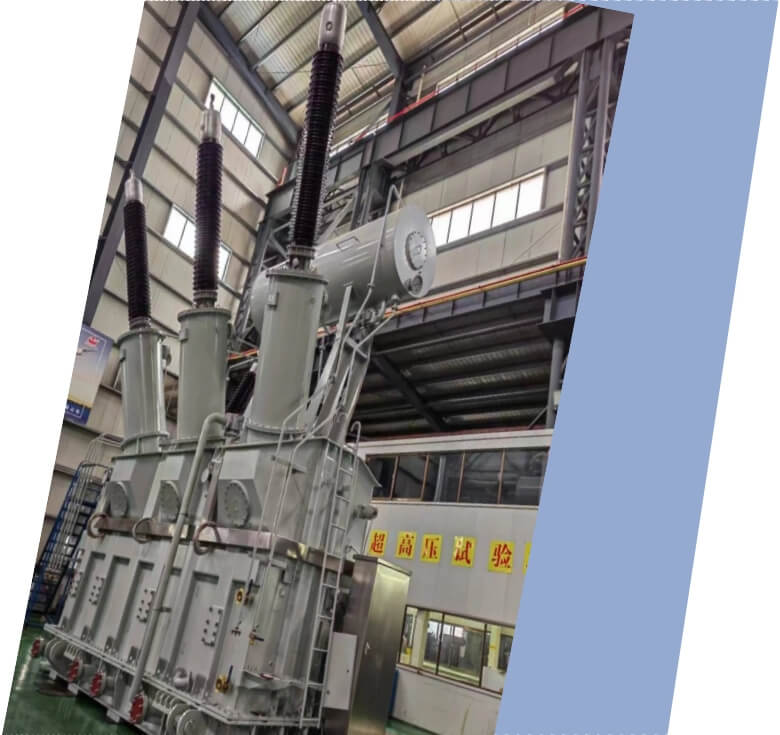

66kV 69kV Power Transformer

- Primary Voltage Ratings 69kV 66kV 63kV or others

- Secondary Voltage Ratings 33/13.8/11 kV or customized

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL Up to 350kV

- Standards IEEE, ANSI, IEC, CSA

- Application Transmission and distribution systems, industrial parks

- Power Rating 5000-400000kVA

- Certificate UL ,CESI ,ISO

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 5000-400000kVA |

| Rating Primary Voltage | 69kV 66kV 63kV or others |

| Secondary Voltage |

33kV 13.8kV 11kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YNd1, Dyn1, YNd11 or others |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

First, the transformer is wrapped in a waterproof plastic film to prevent the humid environment from damaging the equipment. Then, the transformer is fixed to the transportation platform with a sturdy wooden box or steel frame to avoid shaking or impact during transportation. The box is filled with high-density foam material to effectively absorb external vibration and impact, further ensuring the safety of the equipment.

In order to prevent the transformer from being damaged during transportation, shock pads and shock absorbers are also used for additional fixing in the box. For long-distance transportation, the weight and volume of the transformer usually require the use of special transportation tools such as flatbed trucks and containers to ensure its stable transportation.

During transportation, we will provide insurance according to customer requirements to protect the equipment from any potential risks during transportation. The insurance cost is usually calculated according to the value of the equipment and the mode of transportation. If the customer requires special transportation conditions, NPC ELECTRIC can also provide customized packaging services. Before transportation, we will explain the transportation plan and costs to the customer in detail to ensure transparent communication.

After the transformer arrives at the destination, the staff will unload and transport it according to the installation requirements and specifications. After the installation and commissioning work is completed, the customer can put it into use directly. In order to avoid delays, the real-time location of the transformer will be tracked in advance during transportation, and the latest transportation information will be provided to the customer.

Upon arrival, comprehensive installation guides cover safe unloading (via tank lifting lugs or skid), foundation alignment, oil replenishment if partial, bushing/OLTC connections, grounding, and pre-energization checks. Customs documentation (commercial invoice, packing list, certificate of origin, test reports, efficiency certifications) streamlines clearance. Optional pre-shipment third-party or customer witness inspections can be arranged. Coordinated logistics ensure regulatory compliance, minimal delays, and transformer arrival in optimal condition ready for substation commissioning.

Manufacturer Test

Progress test

NPC Electric's 66kV and 69kV power transformers have undergone rigorous production testing during the production process. First, the design and manufacture of the transformers comply with relevant international standards to ensure their stable operation under high-voltage environments. Secondly, a series of tests, including electrical strength, temperature rise, load characteristics, and other tests, were carried out to verify their performance and safety. Then, each key component was inspected in detail to ensure that there were no defects. All test results met the design requirements and were confirmed by the customer. Finally, the transformers were fully commissioned and performance verified to ensure that they can achieve the expected efficiency and reliability in actual operation. il processing tracks dehydration/filtration to <8ppm moisture and >65kV dielectric strength. Surface preparation and primer application are gauged for adhesion before final coating. These phased validations facilitate early defect identification, aligning with efficiency, impedance, and durability benchmarks.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Capacitive bushing test

♦ Measurement of no-load loss and current at 90%,100%,110% of rated voltage

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

NPC Electric conducts rigorous quality control testing on every transformer or representative samples, as well as on specific components and materials, to ensure compliance with design specifications throughout the production process.

The Factory Acceptance Test (FAT) for a power transformer is a critical step performed before shipment to verify that the unit meets all applicable standards and delivers optimal performance. The FAT includes the following key procedures:

Electrical Testing: Involves measuring winding resistance, insulation resistance, and performing turns ratio tests to validate electrical integrity and functionality.

Dielectric Strength Test: Applies high voltage across the insulation system to ensure it can endure both normal and transient operating voltages without failure.

Protection Device Testing: Verifies the proper operation of integrated protective components such as thermal sensors, temperature relays, and tap changers (if applicable).

Routine Test - Test of transformer oil

Dissolved Gas Analyzer (DGA): Detects gases in the oil that indicate internal faults.

Acid Value Tester: Determines the oil's acidity to check for oxidation.

Prepare oil sampling kits, testing instruments (e.g., dielectric strength tester, gas analyzer), and clean containers for oil samples.

Ensure all personnel are equipped with necessary safety gear, such as gloves, goggles, and protective clothing.

Visually inspect the oil for signs of contamination or abnormal color before collecting samples.

Carefully extract oil samples from the transformer at specific locations (such as the oil conservator or top of the tank) to ensure accurate representation of the oil’s condition.

Chemical and Gas Analysis:

The pressure is maintained for a set period (usually 30-60 minutes) to observe if there is any drop in pressure, which could indicate a leak.

ASTM D1816 Dielectric Breakdown Voltage of Insulating Liquids

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.