300kVA Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA

- Application Residential Areas And Small Communities

- Power Rating 300kVA

- Certificate ISO, CE, UL

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 300 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1 - 5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 430 kg | |

| Total Weight | 1650 kg | |

| Outline Dimensions(L×W×H)in. | 1700 × 1250 × 1800(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

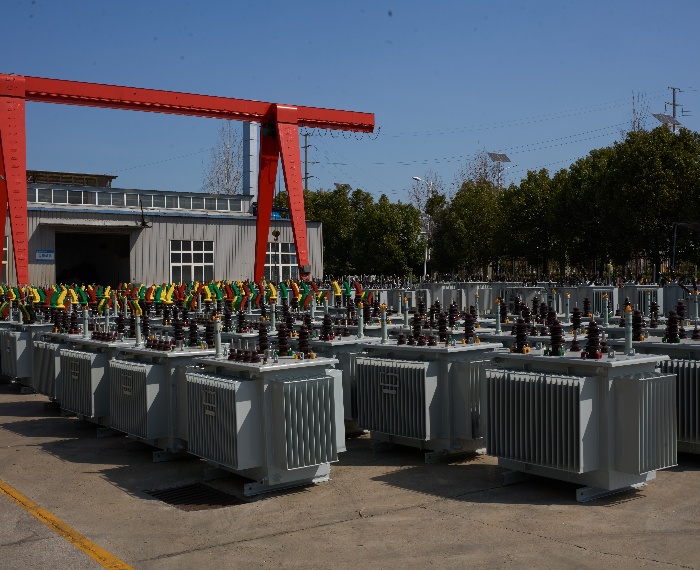

Packing and Shipping

For this purpose, the Packing and Shipping of a 300kVA Three-Phase Oil-Immersed Transformer involves a series of steps to ensure the safe and secure transport of the transformer from the manufacturer to the installation site. The process begins with a thorough inspection and cleaning of the transformer to remove any dirt, debris, or foreign materials. The transformer is then carefully prepared for packaging, with all loose or delicate components, such as bushings, tap changers, and protective devices, securely fastened or removed to avoid any damage during transit.

The transformer is placed onto a sturdy, custom-designed wooden or metal skid, ensuring proper weight distribution and preventing movement during shipping. For added protection, the transformer is wrapped in weather-resistant and moisture-proof materials, such as shrink wrap or tarpaulins, to safeguard against external environmental factors like dust, rain, or temperature variations. Additionally, if the transformer contains oil, the packaging is designed to ensure that the oil remains at the proper level and that there are no leaks or contamination risks during transit.

The transformer is then loaded into a wooden or metal crate that provides additional cushioning and structural integrity to prevent mechanical damage. The shipping crate is appropriately labeled with necessary details, including handling instructions, weight, dimensions, and safety warnings such as "Fragile" or "Keep Upright." The packaging also includes clear instructions on how to safely lift and move the transformer using cranes or forklifts. Once packed, the transformer is ready to be transported via the most suitable mode of transport—truck, rail, or sea container—depending on the distance and delivery method. Upon arrival at the destination, the transformer is carefully unloaded, inspected again for any damage, and prepared for installation. This meticulous packing and shipping process ensures that the transformer reaches its final location in optimal condition and is ready for operation.

Manufacturer Test

Progress Test

NPC Electric manufactures three-phase oil-immersed transformers the strict quality control. The Optional Specifications for a 300kVA Three-Phase Oil-Immersed Transformer offer several customizable features to meet specific operational, environmental, and regulatory requirements. These options can include different types of tap changers, such as manual or on-load tap changers, for adjusting voltage levels while the transformer is in operation. Enhanced protection systems like Buchholz relays, gas-actuated relays, and temperature sensors may be added to monitor internal conditions and ensure safety during fault conditions. The transformer can also be equipped with specialized bushings, such as composite or porcelain, to suit varying voltage levels and environmental conditions. For installations in challenging environments, options for corrosion-resistant coatings, weatherproof enclosures, or special oil types, such as biodegradable or high-performance insulating oils, may be included to extend the transformer's lifespan. Additionally, noise reduction options like acoustic enclosures or vibration dampers may be offered for quieter operation.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

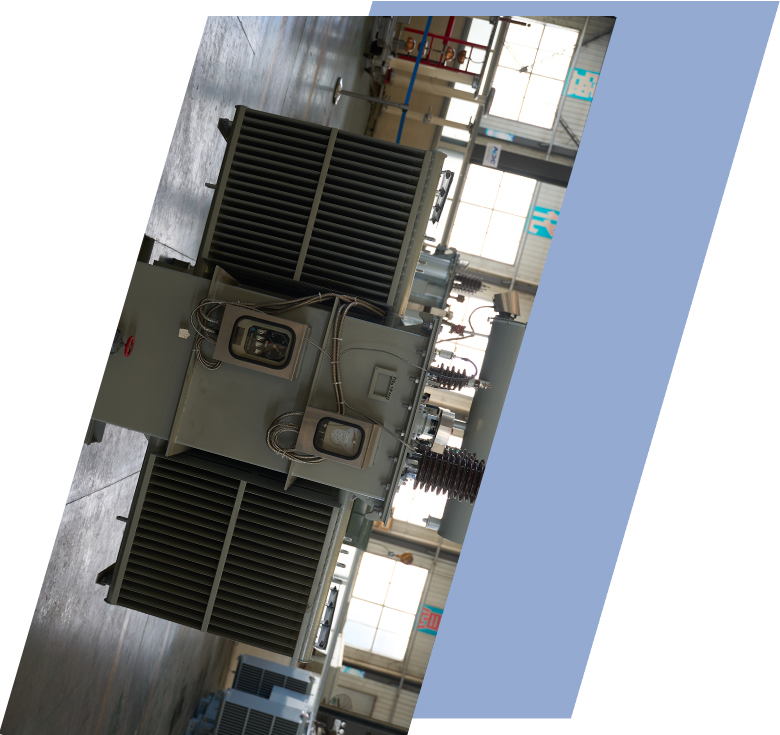

Transformer Factory Acceptance Test

The Transformer Factory Acceptance Test (FAT) for a 300kVA three-phase Oil immersed transformer is an essential procedure conducted before shipment to ensure the transformer meets all required standards and performs optimally. During the FAT, several critical tests are carried out: Shell structural strength: In addition to checking the appearance for damage and deformation, the transformer shell should be properly knocked to check whether the structural strength of the shell meets the requirements and whether there is any internal looseness or abnormal sound. At the same time, check whether the grounding of the shell is good, and the grounding resistance should not be greater than the specified value. Accessory installation accuracy: Check whether the installation angle and spacing of the radiator meet the design requirements to ensure good heat dissipation. The connecting pipe of the oil pillow should not be twisted or blocked, the valve operation should be flexible, and the seal should be reliable. The installation position of the gas relay should be accurate, and the sealing gasket of its connecting flange should be installed correctly without extrusion deformation.

Routine Test - On load Loss Test

Voltage source and current source (usually rated voltage, or adjusted according to the test standard, such as 10 KV, 20 KV, 35 KV, etc.)

Temperature and humidity meter (used to record ambient temperature and humidity for correction of test data)

The test environment should be dry and rainless, with a relative humidity of less than 75% and a recommended temperature range of 20–30°C.

Connect the test equipment to the appropriate terminals of the device under test and ensure that all wiring is correct and the device is well grounded.

Apply Test Voltage:

Apply the specified test voltage at the rated frequency and adjust the low voltage side to maintain the rated current (or specified current).

On-Load Loss Power

Input Power and Output Power

Current

Voltage

Temperature (temperature rise or winding temperature)

Ambient temperature and humidity during the test

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.