Discover the Three Phase Pad Mounted Transformer

Three-phase pad-mounted transformers are crucial components in residential and industrial power systems. Understanding their performance, materials, and design is key to effective power system configuration.

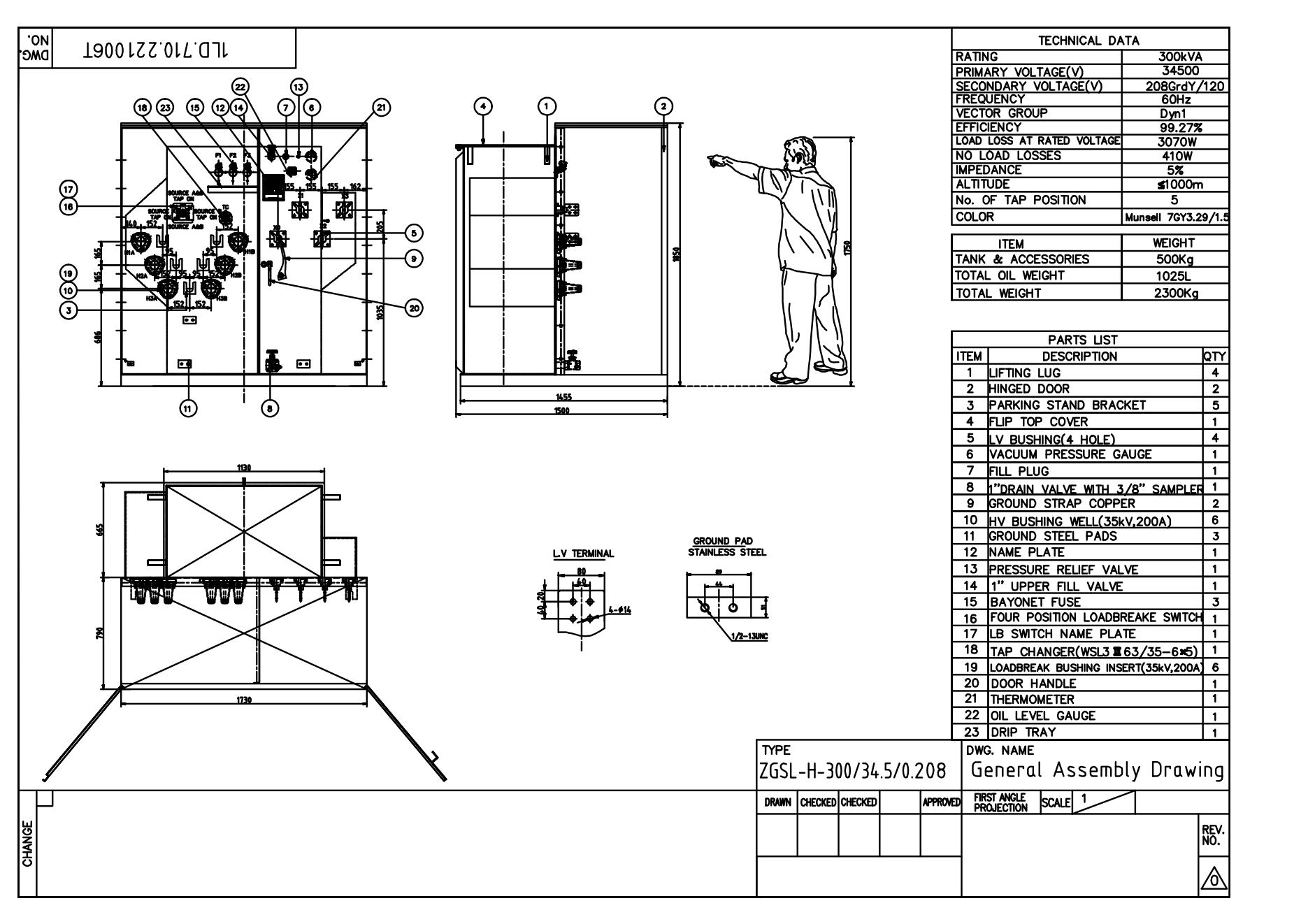

3 Phase Pad Mounted Transformer Standard Parameters

Primary Voltage Ratings: 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

Secondary Voltage Ratings: 208GrdY/120; 416GrdY/240 or Customized

H.V. Tap Range: ± 2×2.5% HV taps or Others

Type: Loop Feed or Radial Feed

BIL: 30/95kV

Standards: IEEE, ANSI, NEMA, ASTM

Application: EV Charging

Power Rating: 45kVA - 5000kVA

Certificate: UL , CESI ,DNV or SGS

Cooling Method: ONAN, KNAN

Oil: Mineral Oil or FR3

Opeartion: Step Down & Step Up

What Is a 3 Phase Pad Mounted Transformer?

A 3-phase Mounted Transformer is a type of electrical transformer that is installed on a concrete pad at ground level. It is fully enclosed in a locked steel cabinet and designed for outdoor use. Unlike pole-mounted transformers, these are safe to be installed in public areas because of their secure design.

These transformers are part of a broader category of pad-mounted transformer systems, engineered to step down medium-voltage electricity (typically 15kV–35kV) to a lower voltage suitable for commercial or residential use (usually 120/208V or 277/480V three-phase power).

How a Three-Phase Pad-Mounted Transformer Works

The three-phase transformer consists of three sets of windings and cores, either integrated in a single tank or configured in banked units. It operates by using electromagnetic induction to convert voltage levels, maintaining power continuity and quality across all three phases.

Inside the sealed enclosure, key components include:

- Primary and secondary bushings

- High-voltage fuses

- Tap changers

- Cooling fins and transformer oil

- Grounding terminals

The interior is filled with insulating fluid, typically mineral oil or environmentally friendly alternatives, to dissipate heat and provide dielectric insulation.

Advantages of a Pad-Mounted Transformer Design

Whether you’re designing an urban substation or powering a neighborhood, the pad-mounted transformer offers several advantages:

1. Safety and Tamper Resistance

The fully enclosed cabinet prevents unauthorized access, making it suitable for sidewalks, alleys, and parks. There's no exposed wiring, reducing the risks of electrocution or vandalism.

2. Space Efficiency

As ground-mounted units, they eliminate the need for utility poles. This not only improves urban aesthetics but also simplifies infrastructure planning.

3. Quiet Operation

Unlike overhead transformers, residential pad-mounted transformers produce minimal noise due to their internal sound-dampening and oil-based cooling systems.

4. Ease of Maintenance

With front-access panels and modular components, field servicing is straightforward. Utilities can quickly perform diagnostics or replace parts with minimal downtime.

Applications of the Three-Phase Pad-Mounted Transformer

The three-phase pad-mounted transformer is widely used in settings that require reliable three-phase power:

- Commercial buildings (shopping malls, office complexes)

- Industrial facilities (factories, warehouses)

- Educational and healthcare campuses

- Data centers

- Large-scale residential developments

For housing developments or apartment complexes, a residential pad-mounted transformer is ideal, especially where underground distribution is preferred.

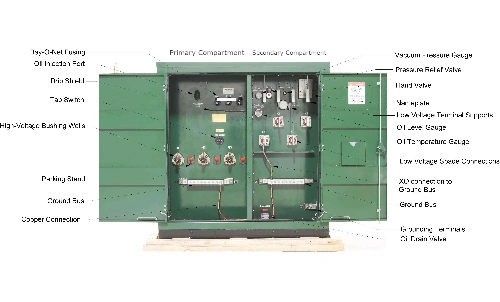

Understanding the Pad-Mounted Transformer Diagram

A typical pad-mounted transformer diagram illustrates the internal and external layout of the system, showing both primary and secondary connections. Key diagram elements include:

- High-voltage input terminals (HV bushings)

- Low-voltage output terminals (LV bushings)

- Grounding bar

- Load-break switches and bayonet fuses

- Cooling and pressure relief components

Engineers and electricians refer to this pad mounted transformer diagram for installation, troubleshooting, and ensuring conformance with electrical codes and standards.

Comparison: 3 Phase vs. Single Phase Pad Mounted Transformer

While both types serve to convert medium voltage to usable voltages, the 3-Phase Pad Mounted Transformer is typically used where large, balanced loads are present. Here’s a quick comparison:

|

Feature |

Single Phase |

3 Phase Pad Mounted Transformer |

|

Output Voltage |

120/240V |

208Y/120V, 480Y/277V |

|

Use Case |

Small homes, light loads |

Commercial, industrial loads |

|

Efficiency in Power Delivery |

Moderate |

High |

|

Load Handling |

Unbalanced loads |

Balanced, high-capacity loads |

Installation Guidelines for Transformer Electrical Systems

Correct installation of a transformer electrical system involves careful planning and compliance with industry standards (e.g., IEEE, IEC, ANSI). Key steps include:

- Site Selection: Choose a location with proper drainage and ventilation. Avoid flood-prone areas.

- Foundation Preparation: A concrete pad must meet load-bearing and leveling standards.

- Grounding: Install a proper ground grid to dissipate fault currents.

- Cable Termination: Ensure high-voltage and low-voltage cables are terminated using proper lugs, and verify tightness with a torque wrench.

- Load Testing: Perform no-load and full-load testing before energizing the system.

All work should be performed by certified professionals to ensure safe integration into the local electrical transformer network.

Maintenance Best Practices

While pad-mounted transformers are built to be low-maintenance, routine checks ensure longevity:

- Visual Inspection: Check cabinet seals, locks, and bushings for corrosion or damage.

- Oil Sampling: Analyze transformer oil annually for dissolved gases and moisture.

- Thermal Scanning: Use infrared cameras to detect hot spots on terminals.

- Ground Testing: Confirm that grounding remains intact and resistance is within spec.

Proactive maintenance reduces unplanned outages and extends service life, especially in high-demand environments.

Future Trends in Pad-Mounted Transformer Technology

As smart grid technology advances, pad-mounted transformer units are being equipped with monitoring sensors and communication modules. These "smart transformers" can:

- Report real-time loading and fault data

- Integrate with SCADA systems

- Enable predictive maintenance through analytics

Environmentally, there's also a push toward biodegradable insulating oils and low-noise designs for urban and residential pad-mounted transformer applications.

The three-phase Mounted Transformer is an indispensable component in modern medium-voltage distribution networks. With its enclosed design, three-phase power capability, and adaptability across commercial and residential sectors, it continues to be a preferred choice for reliable and safe power delivery.

Whether you're an engineer, contractor, or facilities manager, understanding the function and features of the 3-Phase Pad-Mounted Transformer will help you make smarter design and maintenance decisions in your transformer electrical infrastructure.