Pad Mounted Transformer Installation Guide

Pad mounted transformers installation is an important part of the power distribution system. Installing the transformer according to the transformer instructions can maximize the performance of the transformer while avoiding excessive maintenance costs in the future.

This guide provides field technicians and electrical contractors with a comprehensive, step-by-step approach to pad mounted transformer installation, with safety protocols, size selection tips, and post-installation pad mounted transformer maintenance advice.

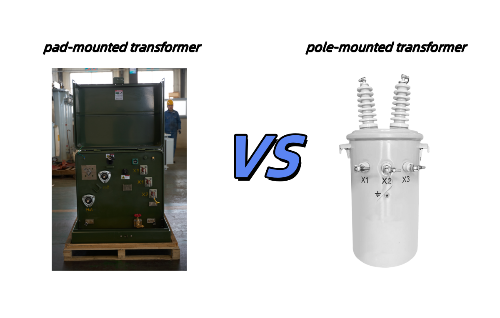

1. Understanding Pad Mounted Transformers

Pad mounted transformers are ground-level units enclosed in weatherproof steel cabinets. They serve as medium-voltage distribution transformers, stepping down primary voltages (15kV–35kV or higher) to low-voltage levels for end-user applications.

Common Applications:

- Residential subdivisions

- Shopping malls and office parks

- Industrial facilities

- Data center campuses

- Renewable energy interconnections

- Municipal infrastructure

2. Pre-Installation Checklist

Before beginning the pad mounted transformer installation, it's essential to ensure site readiness, safety compliance, and compatibility with system specifications.

✅ Site Preparation

- Concrete pad poured and cured per utility specs

- Adequate drainage and clearance for airflow

- Ground grid installed and tested

- Conduit stub-ups aligned with transformer cabinet layout

✅ Safety & Compliance

- Confirm local code and utility requirements

- PPE for all personnel (gloves, hard hats, safety glasses)

- Lockout/Tagout (LOTO) procedures in place

- Confirm transformer rating matches project specs

3. Selecting the Right Pad Mounted Transformer

Choosing the correct pad mounted transformer size is essential to system efficiency, cost-effectiveness, and long-term performance.

Key Factors:

- Primary & Secondary Voltage Ratings (e.g., 13.8kV to 480V)

- kVA Load Capacity (e.g., 75kVA, 150kVA, 500kVA, 2500kVA)

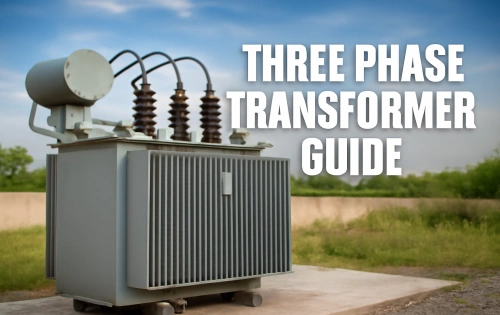

- Single-phase or Three-phase configuration

- Cooling Type: Oil-filled or dry-type

- Compatibility with data center load profiles (if applicable)

Tip: Oversizing leads to higher capital costs, while undersizing risks overheating and early failure. Always match transformer capacity to peak load plus 25–30% safety margin.

4. Step-by-Step Installation Process

Step 1: Receiving & Inspection

- Inspect transformer upon delivery for damage

- Verify nameplate data against specifications

- Check grounding lugs, terminations, and accessories

Step 2: Positioning the Transformer

- Use proper rigging equipment (crane or forklift)

- Lower transformer onto the pad ensuring proper orientation

- Align access doors for safe maintenance access

Step 3: Grounding

- Connect ground lugs to the site’s ground grid using copper wire (#2 AWG minimum)

- Install ground rods where specified

- Ensure continuity with the transformer tank and door bonding

Step 4: Primary & Secondary Cable Connections

- Connect primary medium-voltage cables to bushings A, B, C (three-phase)

- Connect secondary low-voltage cables to terminals X1, X2, X3

- Torque connections per manufacturer specs

- Install load-break elbows and protective boots as needed

Step 5: Testing

- Perform insulation resistance testing (megger)

- Conduct TTR (turns ratio test) and continuity checks

- Power up transformer with no load for 10–15 minutes to observe stability

5. Safety Considerations

Pad mounted transformers installation must prioritize worker and public safety.

- Maintain minimum clearances per NEC/utility code

- Always de-energize lines before accessing terminals

- Use hot sticks or PPE-rated tools for energized testing

- Secure all access panels and padlock doors post-installation

For data center environments, it's crucial to follow N+1 or 2N redundancy protocols when integrating pad mounted units into power chains.

6. Post-Installation Pad Mounted Transformer Maintenance

Proper pad mounted transformer maintenance is key to minimizing downtime and extending asset life.

Routine Maintenance Tasks:

- Monthly visual inspection: Check for leaks, corrosion, or overheating signs

- Annual infrared scan: Detect loose connections or load imbalances

- Oil sampling (if oil-filled): Monitor dielectric strength, moisture, and DGA

- Cleaning: Remove dust, insects, vegetation around transformer

Best Practices:

- Maintain a digital logbook of all service visits

- Check for proper operation of load-break switches and fuses

- Keep spare parts (gaskets, elbows, bushings) on site for critical units

In Power & Energy Industry applications, transformer uptime directly impacts service reliability and regulatory compliance. A preventive maintenance schedule is essential.

7. Common Pad Mounted Transformer Sizes and Ratings

Understanding pad mounted transformer sizes helps in planning for space, budget, and load growth:

|

kVA Rating |

Common Applications |

Dimensions (approx.) |

|

75 kVA |

Residential clusters |

Small footprint (30"x36") |

|

150 kVA |

Small commercial buildings |

Mid-size (40"x42") |

|

500 kVA |

Supermarkets, office buildings |

Large cabinet (50"x60") |

|

1000+ kVA |

Data centers, industrial facilities |

Custom sizes, high cooling |

Always consult manufacturer catalogs or utility-approved drawings for exact sizing and mounting details.

8. Integration with the Power & Energy Industry

In modern infrastructure, pad mounted transformers are essential for enabling decentralized and underground power distribution. They offer low visual impact, enhanced safety, and compatibility with smart grid features.

Industry Use Cases:

- Power & Energy Industry: Substations, renewables, urban grid upgrades

- Data Center: Redundant power distribution, edge facility supply

- Utility-scale infrastructure: Microgrids, switchgear integration

As energy systems evolve with increased digitization and load growth, proper transformer installation practices become even more critical.

In conclusion, correct pad mounted transformer installation is not only a technical task—it’s a foundational step in ensuring safe, efficient, and long-lasting electrical infrastructure. From selecting the right transformer size to proper cabling and ongoing pad mounted transformer maintenance, following industry best practices will help technicians deliver reliable service across sectors like data centers and the broader Power & Energy Industry.