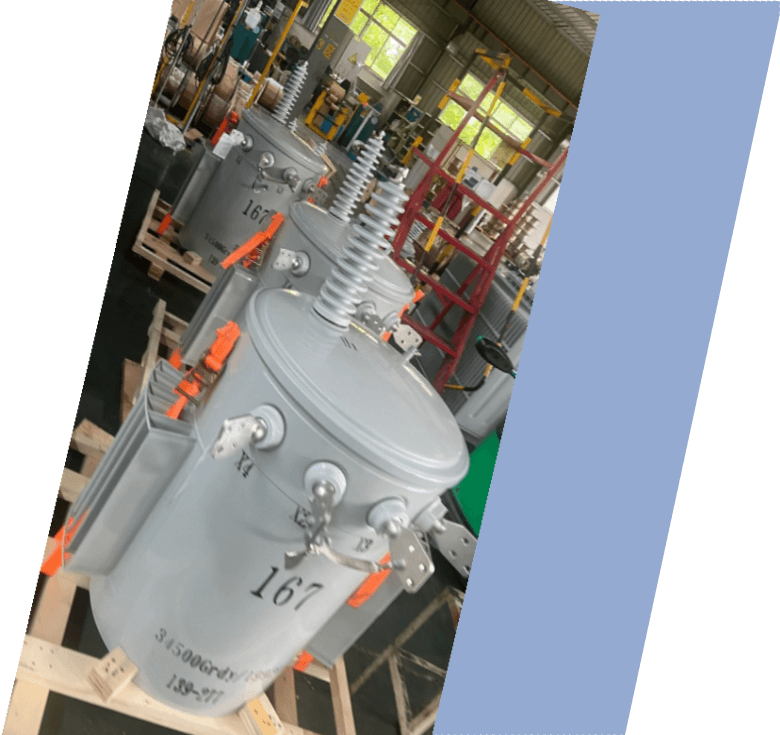

25kVA Conventional Type Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, CSA, DOE

- Application Rural, urban, industrial and commercial areas

- Power Rating 25kVA

- Certificate ISO, CE

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 25 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 45 kg |

| Total Weight | 258 kg |

| Outline Dimensions(W×D×H) | 560×590×935 (mm) |

| Lifting Lug |

| Tap Changer |

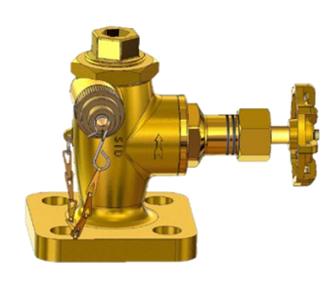

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

The high-voltage side can be selected from 2.4kV, 4.16kV, 7.2kV, 11kV, 13.2kV, 15kV, 19.92kV, 24.94kV, 33kV, etc. to meet the distribution voltage standards of different countries or regions. The low-voltage side can be selected from 120V/240V, 220V/240V, 277V/480V, etc., suitable for residential, commercial and industrial use. The adjustable tap can be selected from the NLTC (No Load Tap Changer): ±2 x 2.5% or ±5% voltage regulation range to adapt to voltage fluctuations.

The transformer insulation level is optional. According to ANSI, IEC or other international standards, common rated insulation levels include BIL (Basic Impulse Level) 30kV, 45kV, 60kV, 95kV, etc., which can be selected according to the lightning protection requirements of the power grid system. Enhanced insulation version suitable for high thunderstorm areas or high altitude environments.

NPC ELECTRIC'S 25kVA Conventional Type Single Phase pole Mounted transformer has optional specifications covering voltage level, insulation level, cooling method, transformer oil, protection device, housing protection, noise control, environmental adaptability, intelligent monitoring function, etc. Users can customize the most suitable transformer configuration according to specific grid requirements, operating environment and special needs to improve the safety, reliability and operating efficiency of the equipment.

Packing and Shipping

Use fully enclosed wooden cases for long-distance transportation or sea transportation to prevent external impact, rain and moisture. Vacuum sealed moisture-proof packaging is suitable for high humidity environments to prevent transformer oil from getting wet or metal parts from rusting.

Anti-seismic cushioning materials fill the packaging with foam, rubber pads or inflatable bags to reduce the impact of vibration and impact on the transformer.

Suitable for international export, usually 20-foot or 40-foot containers are used, and moisture-proof and anti-corrosion treatment is carried out in accordance with international shipping standards. Transformers may be packaged in a single wooden box or multiple transformers may be combined and fixed to maximize loading efficiency. The oil tank must be sealed to prevent moisture or temperature changes during sea transportation, which may cause oil quality deterioration.

The center of gravity is clearly marked on the outside of the transformer packaging to avoid tilting or tipping. Provide lifting hooks or lifting rings for safe handling by forklift or crane. During long-distance transportation, some customers may require the installation of vibration sensors or impact indicators to check for severe collisions upon arrival.

The packaging and transportation of ELECTRIC'S 25kVA Conventional Type Single Phase pole Mounted transformer requires appropriate protective measures according to the specific transportation method and storage conditions to avoid physical damage, environmental factors and quality problems before installation. Manufacturers usually provide standard, reinforced and customized packaging, and ensure safe and reliable transportation, and finally deliver it to the customer site smoothly to ensure the normal operation of the transformer.

Manufacturer Test

Progress Test

NPC ELECTRIC'S 25kVA Conventional Type Single Phase pole Mounted transformer during the manufacturing process, the quality of key materials such as silicon steel sheets, magnet wires, insulation materials, transformer oil, etc. is checked to ensure compliance with standards. Dielectric strength of insulation materials, oil quality analysis, thickness and coating of steel are tested. Winding resistance is measured to ensure the number of coil turns and wire specifications are correct. The insulation strength of the winding is tested to prevent short circuits or inter-turn faults. These tests ensure that the quality of the transformer meets IEC 60076, ANSI C57.12.20 or other international standards. Oil processing monitors dehydration, filtration cycles, and dielectric sampling to reach <10 ppm moisture and >50 kV breakdown strength. These incremental inspections allow early detection and correction of nonconformities, ensuring final product meets efficiency, impedance, and durability requirements.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Factory Acceptance Test (FAT) of NPC ELECTRIC'S 25kVA Conventional Type Single Phase pole Mounted transformer is designed to ensure that the transformer complies with the design specifications and international standards (such as IEC 60076, ANSI C57.12.20). The tests include key performance indicators such as winding resistance, dielectric withstand voltage, no-load and short-circuit losses, insulation resistance, etc. to verify the safety and reliability of the product. Oil quality analysis includes dielectric breakdown, moisture content, acidity, and dissipation factor per ASTM to confirm fluid suitability. Functional verification operates tap changer, fuses, arresters (if CSP), pressure relief device, and oil gauge. Optional witnessed tests may include sound level measurement or temperature rise heat run. Certified test reports with traceable calibration data and customer witness provisions (if requested) document all results, confirming the transformer meets efficiency, dielectric, and safety requirements for reliable overhead service.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.