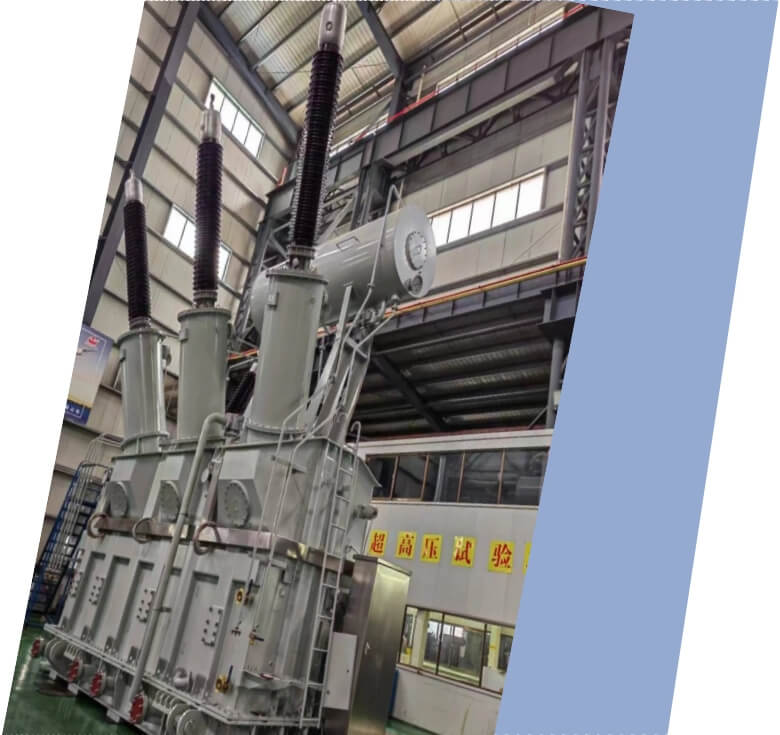

55kV 1600kVA Three Phase Oil Immersed Power Transformer Copper

- Primary Voltage Ratings 69kV 66kV 60kV or others

- Secondary Voltage Ratings 33/13.8/11 kV or customized

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL Up to 350kV

- Standards IEEE, ANSI, IEC, CSA

- Application step-up stations, port & railway electrification, heavy industrial parks

- Power Rating 250-1600kVA

- Certificate UL ,CESI ,ISO

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 250-1600kVA |

| Rating Primary Voltage | 69kV 66kV 60kV or others |

| Secondary Voltage |

33kV 13.8kV 11kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YNd1, Dyn1, YNd11 or others |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

All 55 kV porcelain bushings (HV & LV), neutral bushing, conservator tank (if applicable), radiator panels, OLTC operating handle, cooling fans, Buchholz relay, oil level indicator, winding/oil temperature gauges, sudden pressure relay, and marshalling box are carefully dismantled by certified technicians. Each item is wrapped in VCI anti-corrosion film, placed into custom IPPC-fumigated marine-plywood crates with ≥50 mm high-density anti-shock foam on all sides, and packed with 200 kg silica-gel desiccant per crate. Four 3-axis digital shock recorders (±200 g) and two electronic tilt indicators (±30°) are fixed to every crate. Crates are clearly labeled with part description, serial number, gross/net weight, and multilingual “Extremely Fragile – This Side Up” markings.

The main tank (gross weight approx. 19–23 tons) is welded onto a reinforced steel saddle skid with DNV-certified lifting lugs and 12 heavy-duty lashing points. The entire body is enclosed in a fully sealed wooden crate made of 25 mm marine plywood reinforced with 80×80 mm galvanized steel beams, then double-wrapped with 0.2 mm aluminum-foil moisture barrier and heavy-duty waterproof tarpaulin, heat-sealed at all joints. Eight high-precision digital impact recorders (trigger >3 g) and real-time GPS tilt monitors are permanently attached. External surfaces are painted bright yellow with permanent stenciling in English/Chinese/Spanish: “55kV 1600kVA Three Phase Oil Immersed Power Transformer Copper – Do Not Roll – Keep Dry – Use Spreader Beam Only – Center of Gravity Marked”. IMO Class 9 labels and handling pictograms are applied.

Inland transport is performed by standard low-bed or hydraulic axle trailers (total height ≤4.5 m). Sea freight uses 40 ft open-top/flat-rack containers or break-bulk under-deck stowage with CCS/DNV-approved lashing using Φ22–Φ28 mm steel wire ropes and 50-ton turnbuckles. Full documentation package includes detailed packing list, IPPC fumigation certificate, certificate of origin (Form A/E), nitrogen pressure & trend report, shock recorder baseline data, 110 % all-risk marine insurance, third-party loading survey report, and complete installation manual. These comprehensive measures ensure every 55kV 1600kVA transformer arrives worldwide in perfect, ready-to-energize condition with zero damage.

Manufacturer Test

Progress test

The 55kV 1600kVA transformer is subjected to systematic, fully documented Progress Tests at every major production milestone, allowing real-time quality monitoring and immediate corrective action.

Stage 1 – Active Part Completion

- Individual coil insulation resistance and PI test (>2.5)

- HV & LV winding DC resistance at all tap positions

- Core insulation resistance, grounding current (<70 mA) and core loss preliminary measurement

Stage 2 – Pre-Tanking Verification

- Complete turns ratio test at all tap positions (tolerance ≤ ±0.5 %)

- Vector group and polarity confirmation

- Zero-sequence impedance measurement

- Low-voltage impulse test on each winding to detect turn-to-turn faults

Design Tests

All transformers will be tested after finishing the production test items as follows:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Capacitive bushing test

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

FAT is performed strictly per IEC 60076-1/3/5/11 with full client or third-party (SGS/BV/TÜV) witness and signed protocol.

Tests include:

- Load loss and short-circuit impedance at 75 °C/rated current

- Separate-source applied voltage withstand test

- Induced overvoltage withstand with PD measurement (<10 pC at 1.5Um/√3, <5 pC at Um/√3)

- Full-wave lightning impulse test 250 kV peak (55 kV side)

- Insulation resistance, PI (≥ 2.2), tanδ ≤ 0.004, oil BDV ≥ 70 kV

- Tap-changer full operation: 8–10 cycles at rated current + 50 auxiliary cycles

- Sound level measurement (<58 dB)

Only after client's signature is the transformer released for packing and shipment, guaranteeing 100 % readiness for immediate energization in 55 kV networks worldwide.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.