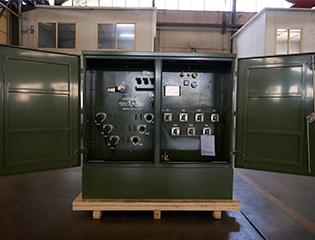

500kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, UL, DOE, CSA

- Application EV charging, Utility, bess, Data center, Oil & Gas, Wind & Solar

- Power Rating 500kVA

- Certificate UL/cUL, CSA, CESI, and other certificates.

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 500 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 1055 L |

| Total Weight | 2700 kg |

| Outline Dimensions(L×W×H)in. | 1.4×1.3×1.75(m) |

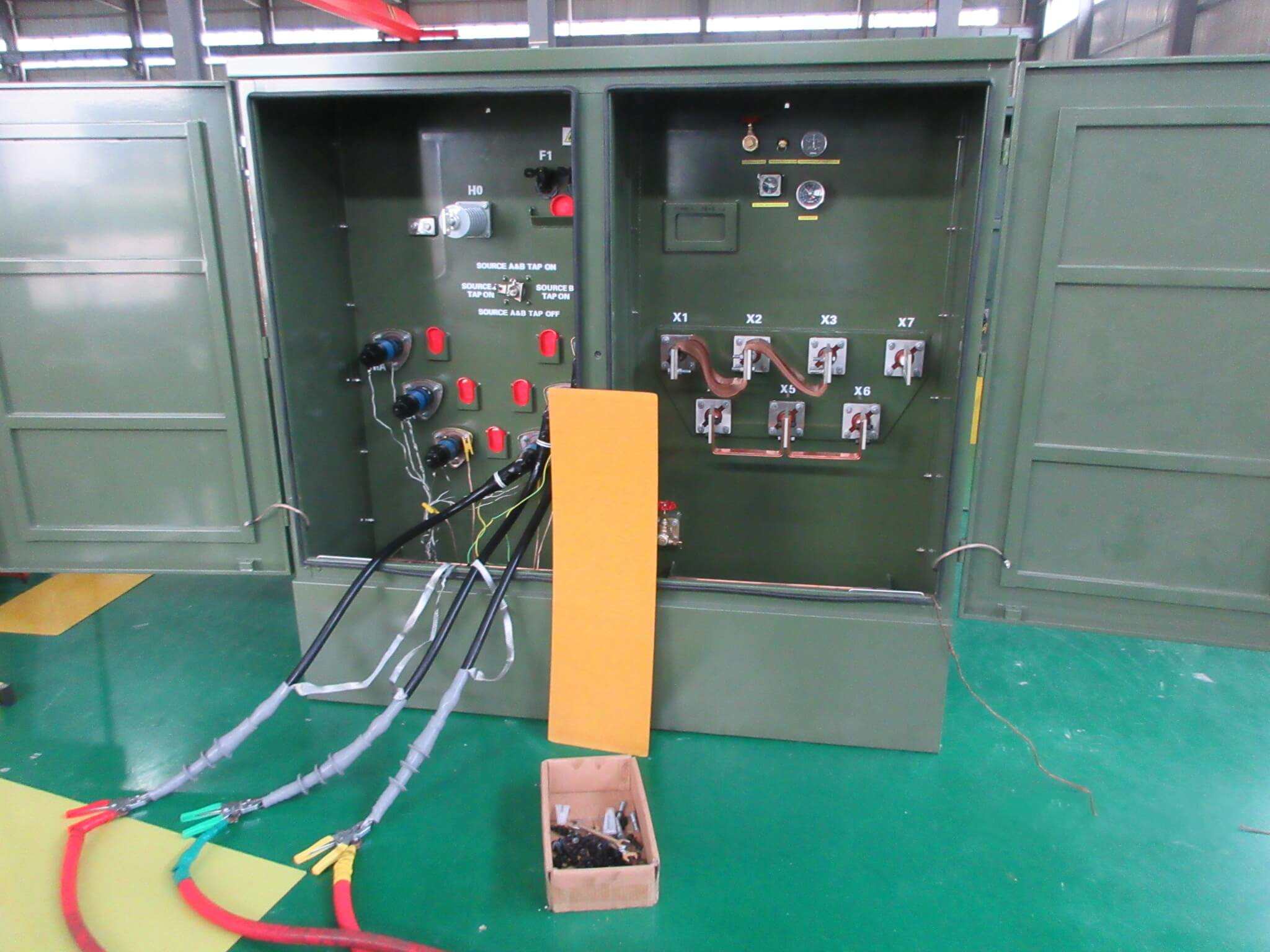

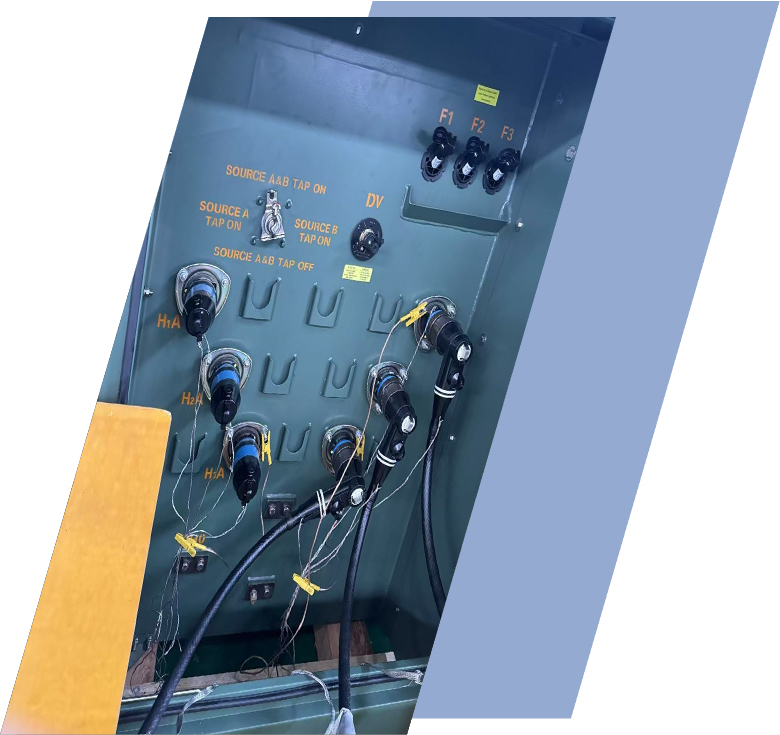

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

The optional specifications for the 500kVA Three-Phase Pad Mounted Transformer offer flexibility to suit various operational requirements and environmental conditions. These options include customizable voltage ratings, such as 13.8kV/480V or 12kV/415V, to match specific power distribution needs.

The transformer can also be equipped with different protection levels, including NEMA 3R, NEMA 4, or IP55 enclosures, providing enhanced weatherproofing and durability for outdoor installation.

Furthermore, the transformer can feature upgraded protection devices, such as overcurrent, surge protection, and temperature monitoring, to ensure safe and reliable operation. These optional specifications allow for tailored solutions, ensuring the transformer meets the specific needs of the customer’s application and operational environment.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

The 500kVA Three-Phase Pad Mounted Transformer is packaged and shipped according to strict industry standards to ensure it reaches its destination in optimal condition. The basic packing and shipping standards typically include:

Packaging:

1.The transformer is securely mounted on a sturdy wooden pallet or skid to prevent any movement during transit.

2.It is wrapped in moisture-resistant plastic or shrink-wrap to protect it from environmental factors such as dust, dirt, and humidity.

3.For additional protection, the transformer may be placed in a custom-built wooden crate or metal enclosure, ensuring it is shielded from external shocks, impacts, and rough handling during transportation.

4.Clear labeling with weight, dimensions, and handling instructions is applied to facilitate proper handling.

Shipping:

1.The transformer is shipped using appropriate modes of transportation, such as flatbed trucks, containers for ocean freight, or air cargo, depending on the destination.

2.It must comply with international shipping standards, ensuring that the transformer is properly secured to prevent shifting and damage during transit.

3.If shipping internationally, the transformer may be packed with export crating to meet the destination country’s import regulations and withstand the conditions of long-distance shipping.

These standards help ensure the transformer’s safe arrival and readiness for installation, while minimizing the risk of damage during transport.

Manufacturer Test

Progress test

Progress tests during fabrication of the 500kVA three phase pad mounted transformer ensure quality adherence at critical production stages. Core assembly verifies lamination precision, clamping torque, and interlayer insulation resistance to achieve minimal core losses and structural integrity. Winding processes include conductor insulation checks, accurate turn and layer placement, sectional continuity testing, and tension control for consistent coils. Core-coil integration preliminary tests feature insulation resistance, hipot screening, and core grounding validation. Tank manufacturing progress involves weld seam inspections (ultrasonic or penetrant), hydrostatic leak pressure testing, surface preparation blasting evaluation, and primer/coating thickness gauging. Assembly checkpoints cover bushing torque verification, accessory alignment, gasket compression assessment, and supervised fluid filling or dry-out monitoring to maintain purity and prevent contamination. The progress test for the 500kVA Three-Phase Pad Mounted Transformer is conducted at various stages of the manufacturing process to ensure that the transformer meets all required specifications and quality standards. These tests are performed during the production phase to monitor the performance and functionality of key components.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory Acceptance Test (FAT) for the 500kVA three phase pad mounted transformer starts with exhaustive visual, dimensional, and mechanical examinations per approved drawings, confirming tank weld quality, enclosure compartmentalization, nameplate accuracy, finish durability, and accessory placement. Insulation resistance megger tests measure windings-to-ground, inter-winding, and core at prescribed voltages, exceeding minimum requirements. Precision TTR turns ratio testing verifies all tap positions within ±0.5% tolerance. Polarity, phase relation, and vector group confirmation uses low-voltage excitation. DC winding resistance is measured and temperature-corrected. No-load loss, excitation current, and efficiency metrics at rated voltage confirm DOE 2016 compliance and acceptable sound levels. Results compile into detailed certified reports, open to client or third-party witnessing, affirming full conformity to IEEE C57.12.34, C57.12.00, ANSI, and efficiency standards before shipment release, ensuring exceptional in-service dependability and performance.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.