750kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE, DOE, CSA

- Application ESS, Bitcoin mining, Industry, Renewable energy

- Power Rating 750kVA

- Certificate UL, cUL, CSA, SGS

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 750 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 1300 kg |

| Total Weight | 3900 kg |

| Outline Dimensions(L×W×H)in. | 1700×600×1850(mm) |

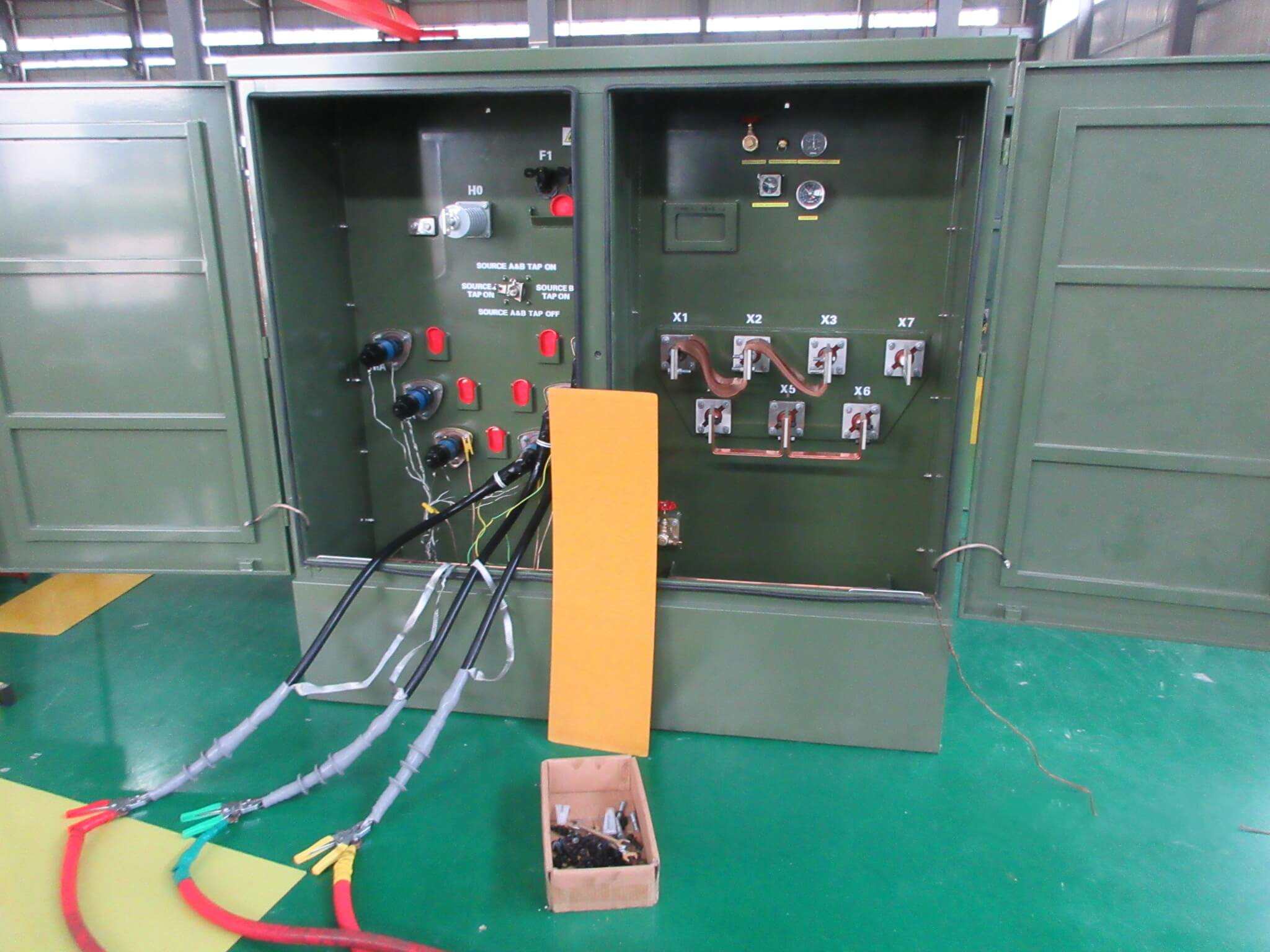

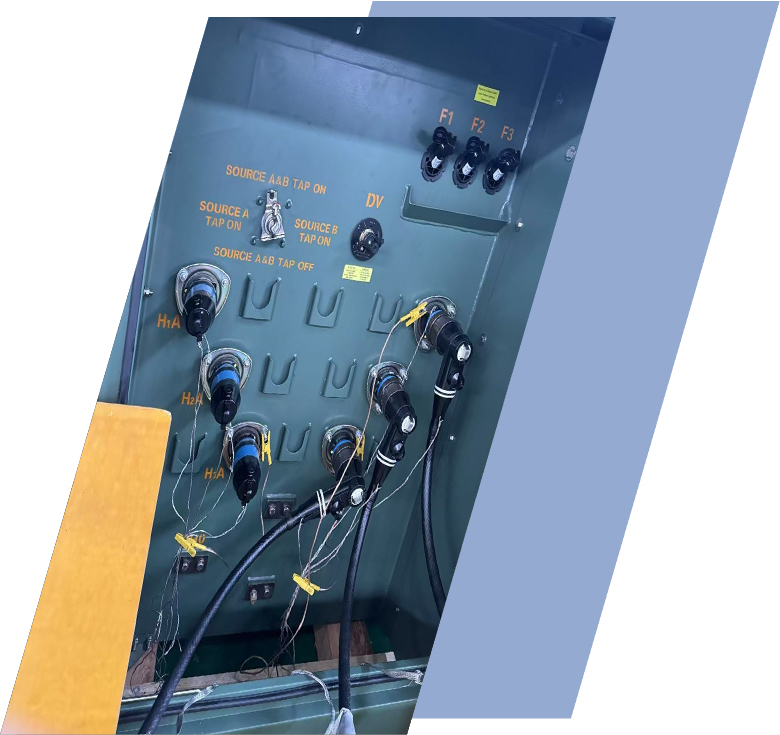

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

The optional specifications for the 750kVA Three-Phase Pad Mounted Transformer provide flexibility to meet specific operational and environmental requirements. These options include customizable voltage ratings such as 13.8kV/480V, 11kV/415V, or other configurations to suit different power distribution needs.

The transformer can be equipped with various enclosure types, including NEMA 3R, NEMA 4, or IP55-rated enclosures, ensuring it can withstand harsh outdoor conditions.

With these flexible options, we ensure that our transformers can be customized for specific applications, environments, and safety standards, offering long-term reliability and performance.

Packing and Shipping

Packaging:

1.The transformer is securely mounted on a durable wooden pallet or skid, preventing any movement during transit and ensuring stability.

2.It is wrapped in moisture-resistant plastic or shrink-wrap to protect it from dust, dirt, and environmental factors like humidity.

3.The transformer is placed in a reinforced wooden crate or metal container, providing additional protection against external shocks, impacts, and rough handling.

4.Proper labeling, including weight, dimensions, and handling instructions, is applied for easy identification and efficient handling.

Shipping:

1.The transformer is shipped using suitable modes of transportation, including flatbed trucks, shipping containers for ocean freight, or air freight, depending on the destination.

2.The packaging is designed to meet international shipping standards, ensuring compliance with regulations for secure transportation by sea, air, or land.

3.Additional export crating is used for long-distance shipments to ensure the transformer remains secure during transit.

4.The package is designed to withstand potential rough handling, ensuring that the transformer arrives at the destination safely, ready for installation.

These packing and shipping standards are in place to minimize the risk of damage during transit, ensuring that the transformer reaches its destination in optimal condition.

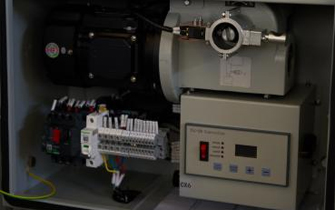

Manufacturer Test

Progress test

Electrical progress tests cover winding resistance at reference temperature, turns ratio validation on all taps, no-load excitation current and preliminary loss measurements to detect core/winding issues early. Impedance and early load loss assessments confirm design targets. Enclosure inspections verify door/latch operation, tamper-resistant integrity, paint thickness/adhesion quality. Fluid dielectric strength and moisture sampling occur during initial processing. All outcomes receive serialized traceable documentation, enabling rapid rectification before proceeding, ensuring continuous compliance with IEEE, ANSI, DOE, and client requirements throughout production for outstanding efficiency, durability, and minimal service risks. Tank production progress involves weld inspections via ultrasonic/penetrant methods, hydrostatic leak pressure testing, surface blasting/prep evaluation, and primer/coating thickness gauging. Assembly phase verifications encompass bushing torque application, accessory positioning, gasket seal compression, and controlled fluid filling or dry-out supervision to ensure contamination-free conditions.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Impedance Voltage & Load Loss (Rated Voltage)

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The Transformer Factory Acceptance Test (FAT) for the 750kVA Three-Phase Pad Mounted Transformer is a comprehensive evaluation conducted at the manufacturer’s facility to ensure the transformer meets all technical specifications and quality standards before shipment. Once all tests are successfully completed, the transformer is certified for shipment, assuring the customer that it will perform safely and reliably throughout its service life. Dielectric withstand testing applies separate-source potential and induced voltage at elevated levels without flashover or partial discharge. Impedance voltage and load loss measurements under short-circuit align with guaranteed parameters. Oil breakdown voltage, moisture, and acidity tests apply for filled units. Functional verifications demonstrate fuse operation, pressure relief activation, gauge accuracy, valve performance, and bushing integrity. Optional tests like sound level assessment, temperature rise simulation, or impulse follow specification. Results compile into certified reports, witnessable by clients/third parties, confirming adherence to IEEE C57.12.34, C57.12.00, ANSI, and efficiency standards before shipment authorization, assuring superior field reliability and performance.

Routine Test - No Load Loss Test

Voltage source (usually 230V, 400V or customized according to customer requirements to adapt to different equipment)

Power analyzer (used to measure power loss and efficiency)

Ammeter and voltmeter

Temperature and humidity meter

Please ensure that the test is carried out in a suitable environment with a relative humidity of less than 75% and avoid rainy days or extreme weather (recommended temperature range: 20-30°C).

Connect the test equipment to the high voltage side of the transformer, making sure the wiring is correct and the equipment is grounded.

Apply Test Voltage:

Usually it is 110% of the rated voltage, for example, if the rated voltage of the transformer is 33 KV, apply 36.3 KV (110%).

No Load Current

No Load Loss

Power Factor

Current

Voltage

Temperature and Humidity

No-load loss < 0.2% ≤ 0.5% rated power (good)

No-load loss > 0.5% rated power (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.