125kVA Oil Immersed Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 480/277V, 400/230V, 380/220V or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Oil immersed distribution transformer

- BIL 30/95kV

- Standards IEEE, ANSI, NEMA, IEC

- Application Commercial Buildings, Power Distribution Substations

- Power Rating 125kVA

- Certificate ISO, CE, UL, IEEE

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Mineral Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 125 kVA | |

| Rating Primary Voltage | 2.4 - 34.5kV | |

| Secondary Voltage | 480/277V 400/230V 380/220V Customized |

|

| Frequency | 50/60Hz | |

| Vector Group | Dyn11, Yyn0, Dyn5 | |

| Winding Material | Aluminum/Copper | |

| Efficiency | As IEEE, Doe 2016, CAS Std or Customized | |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% | |

| Altitude | ≤1,000m or Customized | |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized, etc | |

| Tank material | Mild Steel, 304 Stainless Steel | |

| Insulating Oil Weight | 200 kg | |

| Total Weight | 680 kg | |

| Outline Dimensions(L×W×H)in. | 920 × 590 × 1150(mm) | |

| HV Bushing |

| LV Bushing |

| Tap changer |

| Oil level gauge |

| Oil temperature indicator |

| Pressure relief device |

| Pressure vacuum gauge |

| Lifting hook for complete transformer |

| Name plate |

| Radiators |

| Oil upper filtering valve |

| Oil drain valve with 3/8" sampler |

Customization Optional

The optional specifications of the 125kVA three-phase oil-immersed transformer provide a variety of customized options to meet different application requirements and environmental conditions. Customers can choose different voltage levels (such as different rated voltages for high and low voltage) according to specific requirements to ensure that the transformer is suitable for different power systems. To improve the flexibility of the transformer, users can choose load adjustment devices, such as load or no-load tap switches, to facilitate voltage adjustment according to changes in grid load. In addition, the insulating oil of the transformer can be selected in different types to adapt to special environmental requirements, such as high or low temperature environments, to improve the durability and performance of the transformer. The 125kVA oil immersed transformer offers extensive customization to precisely meet utility, commercial, and industrial project specifications. Primary voltages range from 2.4kV to 34.5kV (common: 34.5kV, 24.94kV, 13.8kV, 13.2kV, 12.47kV, 4.16kV) in delta or grounded wye configurations with BIL up to 200kV. Secondary voltages include 600Y/347V, 480Y/277V, 208Y/120V, 240/120V, or custom outputs with vector groups Dyn11, Dyn1, Yyn0, etc.

With these optional specifications, the 125kVA three-phase oil-immersed transformer can provide more efficient, stable, and safe power solutions according to the specific needs of customers. Enclosure options feature ANSI 70 gray, Munsell green, or custom powder-coated finishes with stainless steel hardware for coastal/high-pollution areas, seismic IBC/OSHPD bracing, high-altitude derating, low-sound designs (<53 dB), and K-factor ratings for harmonic-rich loads (data centers, EV charging). Special designs support solar/wind inverter duty, rectifier loads, or dual-voltage primaries. Every customization is fully engineered and validated to exceed IEEE, ANSI, IEC, DOE 2016/2029 efficiency, and client specifications while minimizing total ownership cost.

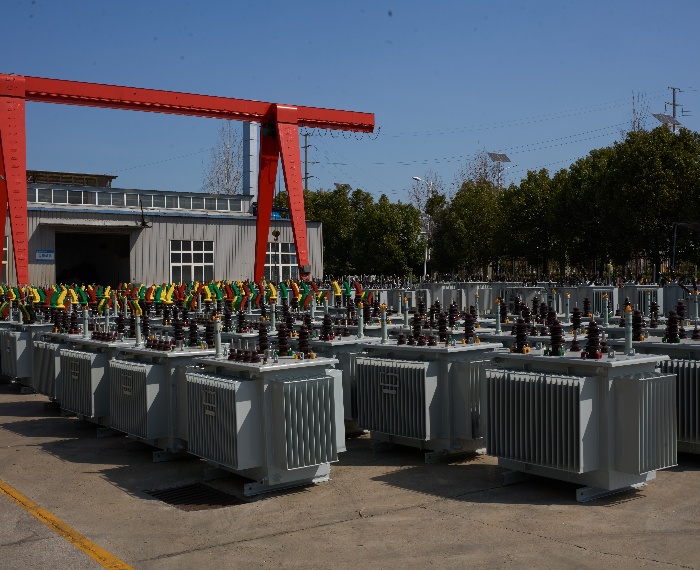

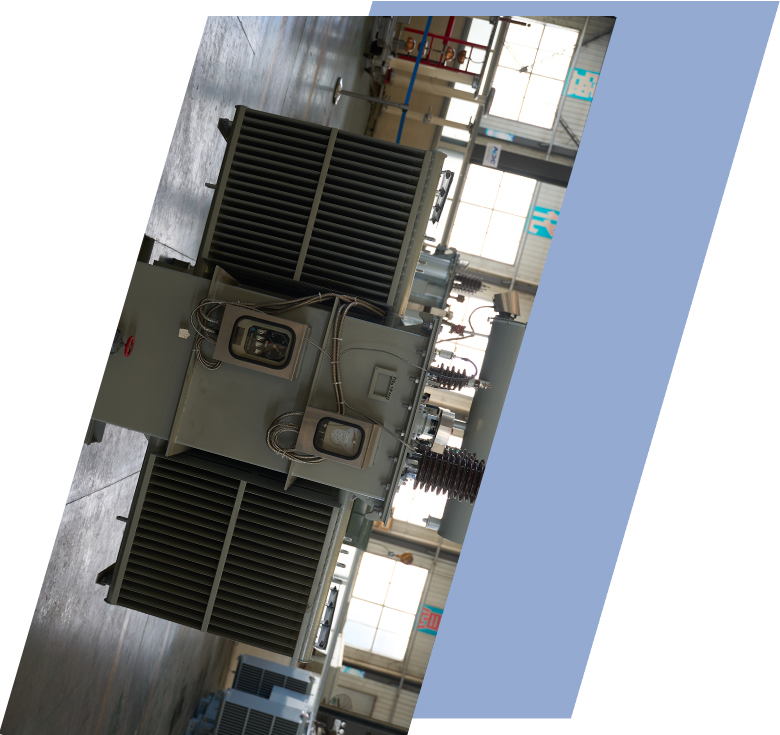

Packing and Shipping

For this purpose, the packaging and transportation process of 125kVA three-phase oil-immersed transformers is strictly carried out in accordance with international standards to ensure that the equipment is fully protected during transportation and avoid any damage or quality problems. First of all, the transformer will be carefully packed in a sturdy wooden outer packaging box or steel frame, and the outside will be protected with waterproof and moisture-proof materials to avoid the impact of moisture or bad weather during transportation. In order to avoid damage to the equipment due to vibration, the transformer will be wrapped with vibration pads, foam boards, bubble films, and other flexible materials to ensure that it is stable and fixed during transportation to prevent the transformer from moving in the box. In addition, the oil tank of the transformer will be sealed to ensure that the insulating oil will not leak and maintain the oil level within a safe range. Clear transportation warning labels, such as "keep dry", "fragile", "moisture-proof", etc., will also be marked on the packaging box to remind the handling personnel to pay attention to the fragile nature of the equipment. The mode of transportation will be selected according to the destination and customer requirements, which may include land transportation, sea transportation, or rail transportation, and ensure that the transportation vehicle has good ventilation and stability to avoid any unstable factors during transportation. If it is international transportation, relevant customs documents, export license, and commercial invoice will be provided with the goods to ensure smooth customs clearance and meet the import requirements of the destination country. Finally, the transformer will be arranged to be safely delivered to the destination, unloaded, and inspected to ensure that the product is delivered to the customer intact.

Upon delivery, detailed instructions cover safe unloading (via tank lifting lugs), positioning, oil top-off if required, grounding, accessory connections, and pre-energization checks. Comprehensive documentation — commercial invoice, packing list, certificate of origin, certified test reports, material certificates — ensures smooth customs clearance. Third-party pre-shipment inspection or customer witnessing can be arranged. Our logistics team guarantees regulatory compliance, minimal delays, and transformer arrival in perfect condition ready for immediate installation and commissioning.

Manufacturer Test

Progress Test

The Progress Test of a 125kVA three-phase oil-immersed transformer is a series of intermediate tests performed during the transformer production process to ensure that the design requirements are met at each stage of manufacturing and to detect potential problems early. Mainly include: 1. Winding resistance test: During the winding production process, resistance measurement is performed to ensure that the winding is not open or short-circuited and to verify the correctness of the electrical connection. 2. Insulation resistance test: The insulation performance of the winding and other key parts is tested to ensure that there are no insulation defects during the production process to avoid electrical failures in the later stage. 3. Voltage ratio test: After the initial assembly, the voltage ratio test is performed to ensure that the input-output voltage ratio of the transformer meets the design specifications.4. Preliminary load loss test: The load loss test is performed when the transformer is initially completed to evaluate its energy efficiency under different loads so that problems can be detected early.

Design Tests

All transformers will be tested after finishing the production, test items as follows:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Polarity, 1-Ph / Phase Relation, 3-Ph (Rated Voltage)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Factory Acceptance Test (FAT) is the final verification step to ensure that 125kVA three-phase oil-immersed transformers meet all design, performance, and safety requirements before leaving the factory. This test is performed after the transformer is fully assembled and oil-filled, and usually includes the following: 1. Winding Resistance Test: Test the resistance value of the transformer winding to ensure that the electrical connection and insulation performance of the winding are good to avoid electrical failures. 2. Insulation Resistance Test: Check the insulation performance of each part of the transformer, especially the winding, casing, and grounding system, to ensure that it has good electrical insulation and prevent electrical leakage. 3. Load loss and no-load loss test: Evaluate the energy efficiency of the transformer under different load conditions to ensure that the energy loss is minimal when running at no load and load, and meet the standard requirements. 4. Short-circuit impedance test: Simulate short-circuit conditions to verify the electrical performance of the transformer when facing a short circuit, ensuring the safety and short-circuit resistance of the equipment.

Routine Test - Transformer Turns Ratio/TTR (All Tap Voltages)

Voltage source: usually AC 10 V to 30 V , used to test different voltages for each tap.

Temperature and humidity meter: used to record environmental conditions during the test to ensure test accuracy.

Current probe: used to measure the load current of the winding and ensure the accuracy of the test results.

Perform the test under suitable environmental conditions: relative humidity below 75% and no rain (recommended temperature: 20-30°C). Avoid high humidity or bad weather that may affect the test accuracy.

The voltage ratio between the windings

Deviation of the measured value from the rated ratio

0.5% < Turns ratio error ≤ 1% (caution)

Turns ratio error > 1% (further inspection or corrective action required)

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.