2000kVA Three Phase Pad Mounted Transformer

- Primary Voltage Ratings 34.5-19.92/13.8-7.957/13.2-7.62/12.47-7.2, 24.94, 26.25, 33 or others

- Secondary Voltage Ratings 208GrdY/120;416GrdY/240 or Customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Loop Feed or Radial Feed

- BIL 30/95kV

- Standards IEEE,ANSI, CSA,CAN, DOE

- Application BESS, Data center, Industry, Renewable energy

- Power Rating 2000kVA

- Certificate UL, CUL, CSA, SGS

- Cooling Method ONAN, ONAN/ONAF, KNAN, KNAN/KNAF

- Oil Minerial Oil or FR3

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 2000 kVA |

| Rating Primary Voltage | 4.16-34.5kV or customized |

| Secondary Voltage | 480GrdY/277 208GrdY/120 400GrdY/230 Customized(208Y/120 V to 4,160 V) |

| Frequency | 50/60Hz |

| Vector Group | Dyn1/Yyn0/Dyn11/Dyn5 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 3.5% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 850 kg |

| Total Weight | 4600 kg |

| Outline Dimensions(L×W×H)in. | 2380×1600×2220(mm) |

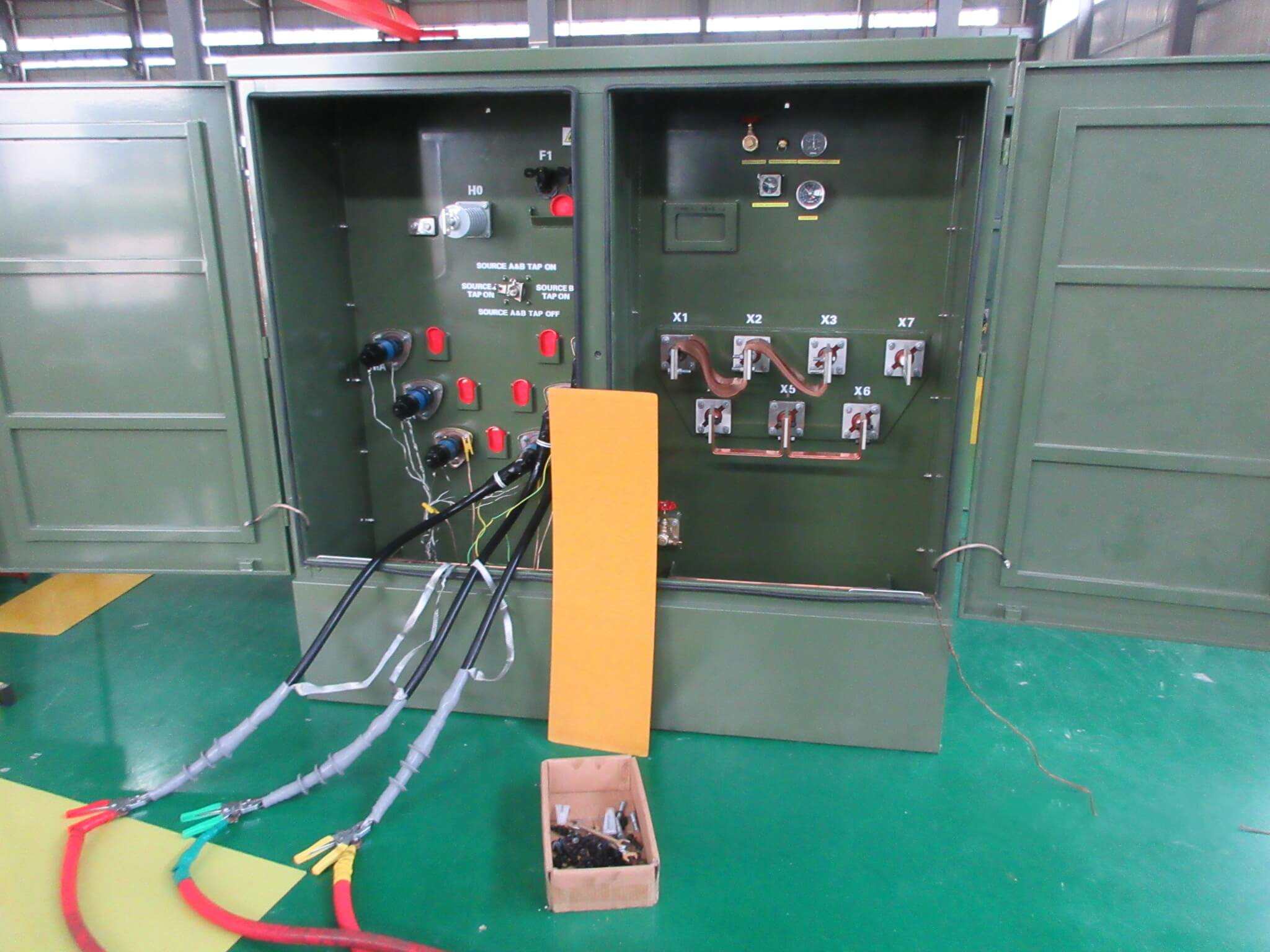

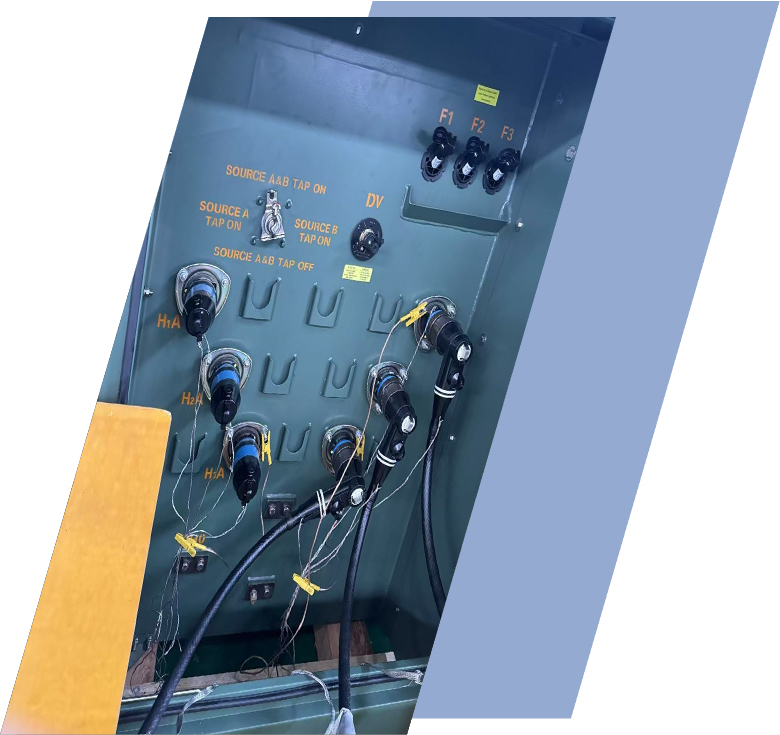

| Lifting Lug | ELSP Fuse |

| Hinged Door | BAY-O-NET Fuse |

| Parking Bracket | Tap Changer |

| Tank Cover | Oil Level Gauge |

| L.V Bushing (4-Hole ) | Pressure Relief Valve |

| Two/Four Position Load break Switch | Vacuum Pressure Gauge |

| HV Grounding Copper Bar | Terminal Block |

| Temperature Indicator | Door Handle |

| H.V Bushing Well(15kV) | Ground Strap |

| Grounding Copper Bar | Nameplate |

| 1"'Drain Valve With 3/8" Sampler | IR Window |

| 1" Upper Fill Valve Filter Press Connection | Terminal Box |

| Non-PCB decal | High Voltage Warning Signs |

Customization Optional

For input voltage (high voltage side), it can provide high voltage input of different levels such as 10kV, 15kV, 20kV, 35kV according to the needs of the power grid, adapting to the power systems in different regions. Low voltage output can be selected from 208V, 400V, 415V, 480V, 600V, etc. to adapt to different applications such as industry, commerce and data centers.

Cooling method:ONAN (oil-immersed self-cooling) or ONAF (forced air cooling), suitable for different load conditions and improve heat dissipation efficiency.

Protection level:The transformer box can be selected from IP44, IP54, IP55 to ensure safe operation in harsh environments such as moisture, dust, salt spray, etc.

Our optional configurations are designed to provide greater flexibility, better adaptability and better performance, ensuring that the transformer can meet the requirements of various complex power grid environments. If you need customization or more information, please contact our technical team!

Packing and Shipping

High-strength wooden box packaging - Use corrosion-resistant, waterproof and moisture-proof wooden boxes or metal frames for packaging to ensure that the transformer will not be affected by the external environment during long-term sea transportation and keep the equipment intact.

Anti-seismic buffer design - Foam pads, rubber supports, wood brackets and other efficient buffer materials are used inside the transformer to firmly fix the transformer in the packaging box, minimize vibration and impact during transportation, and avoid damage to the equipment.

Moisture-proof and anti-corrosion treatment - During the packaging process, we will encapsulate the outside of the transformer with a moisture-proof film and use anti-corrosion paint to treat the external metal parts to prevent rust caused by a humid environment.

Shockproof and stable loading - The transformer is loaded in containers or specially customized transport frames to ensure stability and safety during sea transportation and avoid excessive shaking or collision.

Transport insurance - Provide full transport insurance services to ensure that if any unexpected situation occurs during the transportation of the transformer, customers can receive compensation in time to protect their interests.

Through careful packaging design and professional shipping guarantee, NPC electric ensure that 2000KVA three-phase American box-type transformers can be safely and reliably delivered to customers around the world, and ensure that the equipment can be put into use in the best condition.

Manufacturer Test

Progress test

During the manufacturing process of 2000KVA Three Phase Pad Mounted transformer, NPC electric implemented strict progress testing. All raw materials and key components (such as cores, windings, insulation materials, etc.) were strictly inspected to ensure compliance with design specifications. Process testing was performed on key links such as core assembly, winding processing, and oil immersion to ensure that the production process was carried out as planned and met the design standards. Progress testing is not only a monitoring of various indicators in the production process, but also a timely discovery and resolution of potential problems to ensure the final delivery quality of the transformer. Core assembly inspections verify magnetic balance across three phases, while winding process checks ensure conductor alignment and insulation consistency. Intermediate electrical measurements, including insulation resistance and turns ratio testing, confirm that the 2000kVA three phase pad mounted transformer meets design parameters before final enclosure assembly.

Design Tests

All transformer will be test after finished the production, test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Transformer Turns Ratio/TTR (All Tap Voltages)

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

Before the 2000KVA Three Phase Pad Mounted transformer leaves the factory, we will conduct a strict factory acceptance test (FAT) to ensure that the performance of the transformer meets the design requirements and passes the inspection of relevant international standards to ensure the quality and reliability of the equipment. During Factory Acceptance Testing, the 2000kVA Three Phase Pad Mounted Transformer is evaluated for efficiency, thermal stability, and operational consistency. No-load and load loss measurements, temperature rise assessments, and functional checks of switching and protection components are performed. Completion of the FAT process confirms that the 2000kVA three phase pad mounted transformer is ready for reliable operation in demanding distribution environments.

Routine Test - DC Insulation Resistance Test

Voltage source (usually 500V, 1000V, 2500V, or customized according to customer requirements)

Temperature and humidity meter (used to record the ambient temperature and humidity during the test to ensure that the test conditions meet the standard requirements.)

Perform the test under suitable environmental conditions. It is recommended to have a relative humidity below 75%, no rain, and a temperature range of 20-30°C to avoid moisture or temperature fluctuations affecting the test results.

Connect an insulation resistance tester to the high voltage terminal of the device under test and to ground.

Apply Test Voltage:

Select an appropriate test voltage based on the rated voltage of the equipment .

Insulation resistance value (MΩ)

Applied voltage

Ambient temperature and humidity during testing

500 MΩ ≤ Insulation resistance < 1000 MΩ (good)

100 MΩ ≤ Insulation resistance < 500 MΩ

Insulation resistance < 100 MΩ

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.