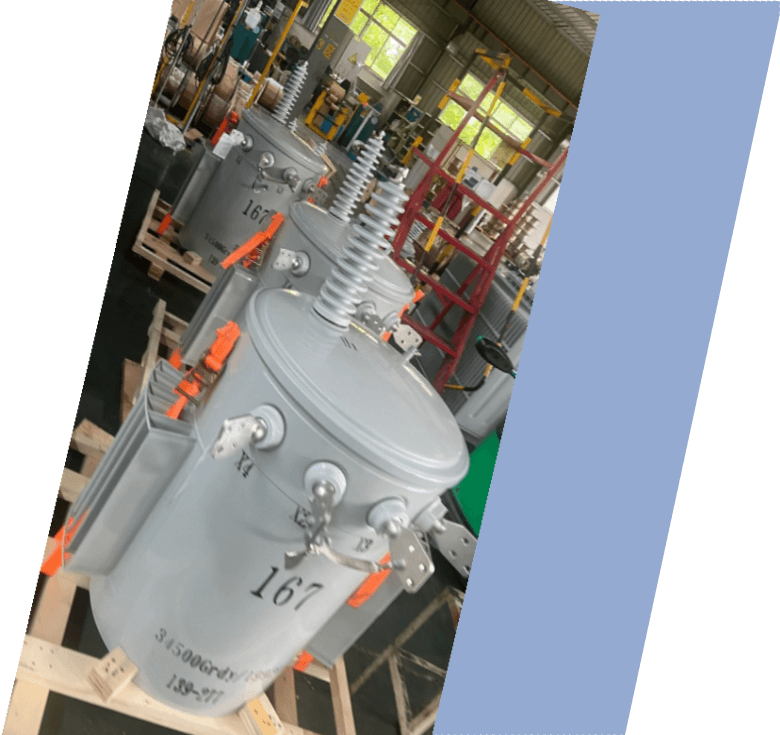

37.5kVA Conventional Type Single Phase Pole Mounted Transformer

- Primary Voltage Ratings 2.4-34.5kV

- Secondary Voltage Ratings 480-240/240-120 or customized

- H.V. Tap Range ± 2×2.5% HV taps or others

- Type Conventional Type

- BIL 30-150kV

- Standards IEEE, ANSI, CSA , DOE

- Application Residential, commercial, rural power grids

- Power Rating 37.5kVA

- Certificate CE, ISO

- Cooling Method ONAN, KNAN

- Oil Mineral Oil or FR3

- Opeartion Step Down

Technical Specifications

| Rated Power | 37.5 kVA |

| Rating Primary Voltage | 12.4-34.5kV |

| Secondary Voltage | 480-240V 240-120V 277V Customized |

| Frequency | 50/60Hz |

| Vector Group | Ii0,Ii6 |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE,Doe 2016,CAS Std or Customized |

| Impedance Voltage | Nominal 2% or Customized 1.1-5.75% |

| Altitude | ≤1,000m or Customized |

| Color | ANSI 70 Light gray/Munsell 7GY3.29/1.5 or customized etc |

| Tank material | Mild Steel, 304 Stainless Steel |

| Insulating Oil Weight | 50 kg |

| Total Weight | 340kg |

| Outline Dimensions(W×D×H)in. | 610×625×935 (mm) |

| Lifting Lug |

| Tap Changer |

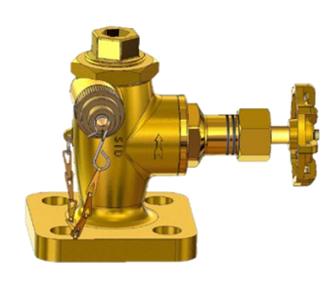

| Pressure Relief Valve |

| Tank Cover and clamp |

| L.V Bushing |

| HV Bushing |

| Ground Strap |

| Nameplate |

| Non-PCB decal |

| High Voltage Warning Signs |

| Suport lug |

| Oil fill valve |

Customization Optional

The high voltage side (Primary Voltage) can choose common standard voltages, such as 7.2kV, 11kV, 13.2kV, 15kV, 19.92kV, 22kV, 24.94kV, 33kV, etc., suitable for different distribution networks. The standard options for the low voltage side (Secondary Voltage) include 120/240V, 220/240V, 230/460V, and the voltage level that meets the power supply requirements of specific regions can also be customized.

The insulation system can be selected from Class A (105°C), Class B (130°C), Class F (155°C) or Class H (180°C) to meet different temperature rise requirements. The lightning impulse tolerance (BIL, Basic Impulse Level) can be selected from 75kV, 95kV, 125kV and higher, suitable for areas with frequent thunderstorms.

Regarding the type of transformer oil, choose mineral oil with good insulation performance and widely used in distribution networks. Biodegradable oil is suitable for areas with high environmental protection requirements, such as water source protection areas, forests and environmentally sensitive areas.

NPC ELECTRIC'S 37.5kVA Conventional Type Single Phase Pole Mounted Transformer offers a variety of optional specifications, including voltage level, insulation level, cooling method, oil type, protection device, installation method and intelligent monitoring options. These options enable the transformer to adapt to different application environments, such as residential power supply, commercial facilities, rural power grids, industrial loads, harsh climates and smart grid systems, providing customers with efficient and reliable power distribution solutions.

Packing and Shipping

Transformers are usually fixed with steel bases for easy forklift handling and installation. Anti-rust coating is applied on the outside to prevent metal parts from moisture or oxidation during transportation. Key components (such as high-voltage/low-voltage bushings, lightning arresters) are protected with foam cushioning materials or plastic protective covers to avoid vibration damage. Product labels, warning signs (anti-shock, anti-moisture, center of gravity position) and transportation instructions are clearly marked on the outside of the package to ensure safe loading and unloading.

For large-scale exports, 20-foot or 40-foot containers can be used to maximize loading efficiency and enhance transportation stability. Highly corrosion-resistant materials and anti-salt spray coatings are used to extend product life. Special weather-resistant sealing measures are provided for cold or high-temperature areas to ensure that the transformer is not affected by the environment during storage and transportation.

The center of gravity position is marked on the outside of the package to ensure that it does not tilt during lifting or loading. Lifting lugs or lifting hooks are provided to ensure safe and reliable loading and unloading. Vibration indicators or impact recorders can be installed as an option to monitor whether abnormal impacts occur during transportation.

The packaging and transportation of NPC ELECTRIC'S 37.5kVA Conventional Type Single Phase Pole Mounted Transformer must ensure that the equipment is protected from physical damage, environmental impact and external contamination during storage, handling and delivery. The manufacturer provides standard, reinforced and customized packaging, combined with land, sea and air transportation to meet the safe transportation needs of different regions and working conditions, ensuring that the transformer can be delivered to the end user safely and efficiently, and maintain optimal performance before installation.

Manufacturer Test

Progress Test

NPC ELECTRIC'S 37.5kVA Conventional Type Single Phase Pole Mounted Transformer production process testing is designed to ensure that each critical stage in the manufacturing process meets technical specifications and quality standards. Tests include coil winding resistance testing, core loss testing, insulation withstand voltage testing, partial discharge detection, and no-load and short-circuit testing to verify components and overall performance. All tests are performed in accordance with IEC 60076, ANSI C57.12.20 or relevant international standards to ensure product quality and reliability. Production process testing can detect manufacturing defects in a timely manner and prevent unqualified products from entering the next stage. Through these tests, it is ensured that the transformer meets the technical requirements of final delivery and has the ability to operate stably for a long time. Oil processing monitors dehydration, filtration cycles, and dielectric sampling to reach <10 ppm moisture and >50 kV breakdown strength. These staged inspections allow early detection and correction of nonconformities, ensuring final product meets efficiency, impedance, and durability requirements.

Design Tests

All transformers will be tested after finishing the production test items as below:

♦ Insulation Power Factor

♦ Ratio, Polarity, and Phase Relation

♦ Winding Resistance

♦ Impulse Tests

♦ On Load Loss Test

♦ No Load Loss Test

♦ Leak Test

♦ DC Insulation Resistance Test

♦ Polarity, 1-Ph

♦ Excitation & No-Load Loss (Rated Voltage)

♦ Applied Voltage

♦ Induced Voltage

♦ Lightning Impulse

♦ Insulation Resistance (Rated Voltage)

♦ Temperature Rise

♦ Dielectric Withstand (Hipot)

Transformer Factory Acceptance Test

The factory acceptance test of NPC ELECTRIC'S 37.5kVA Conventional Type Single Phase Pole Mounted Transformer includes winding resistance measurement, dielectric withstand voltage test, no-load and short-circuit loss test, insulation resistance measurement, etc. to verify the safety and reliability of the product. Routine visual and mechanical inspections check tank weld quality, paint uniformity, nameplate information, accessory mounting, and enclosure integrity. Winding resistance is measured across all tap positions at reference temperature to confirm conductor uniformity and match design loss values. Turns ratio (TTR) testing verifies ratio accuracy within 0.5% tolerance and correct polarity/vector group. Insulation resistance (megger) evaluates winding-to-winding and winding-to-ground paths for high megohm readings. Power-frequency applied potential withstand applies rated test voltage for one minute to HV and LV windings separately per BIL class without flashover or corona.

Routine Test - On load Loss Test

Voltage source and current source (usually rated voltage, or adjusted according to the test standard, such as 10 KV, 20 KV, 35 KV, etc.)

Temperature and humidity meter (used to record ambient temperature and humidity for correction of test data)

The test environment should be dry and rainless, with a relative humidity of less than 75% and a recommended temperature range of 20–30°C.

Connect the test equipment to the appropriate terminals of the device under test and ensure that all wiring is correct and the device is well grounded.

Apply Test Voltage:

Apply the specified test voltage at the rated frequency and adjust the low voltage side to maintain the rated current (or specified current).

On-Load Loss Power

Input Power and Output Power

Current

Voltage

Temperature (temperature rise or winding temperature)

Ambient temperature and humidity during the test

Application

Technical Advantages

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.