Transformers

Substation Transformer

Oil Immersed Power Transformer 200kVA for Substation With Transformer Oil

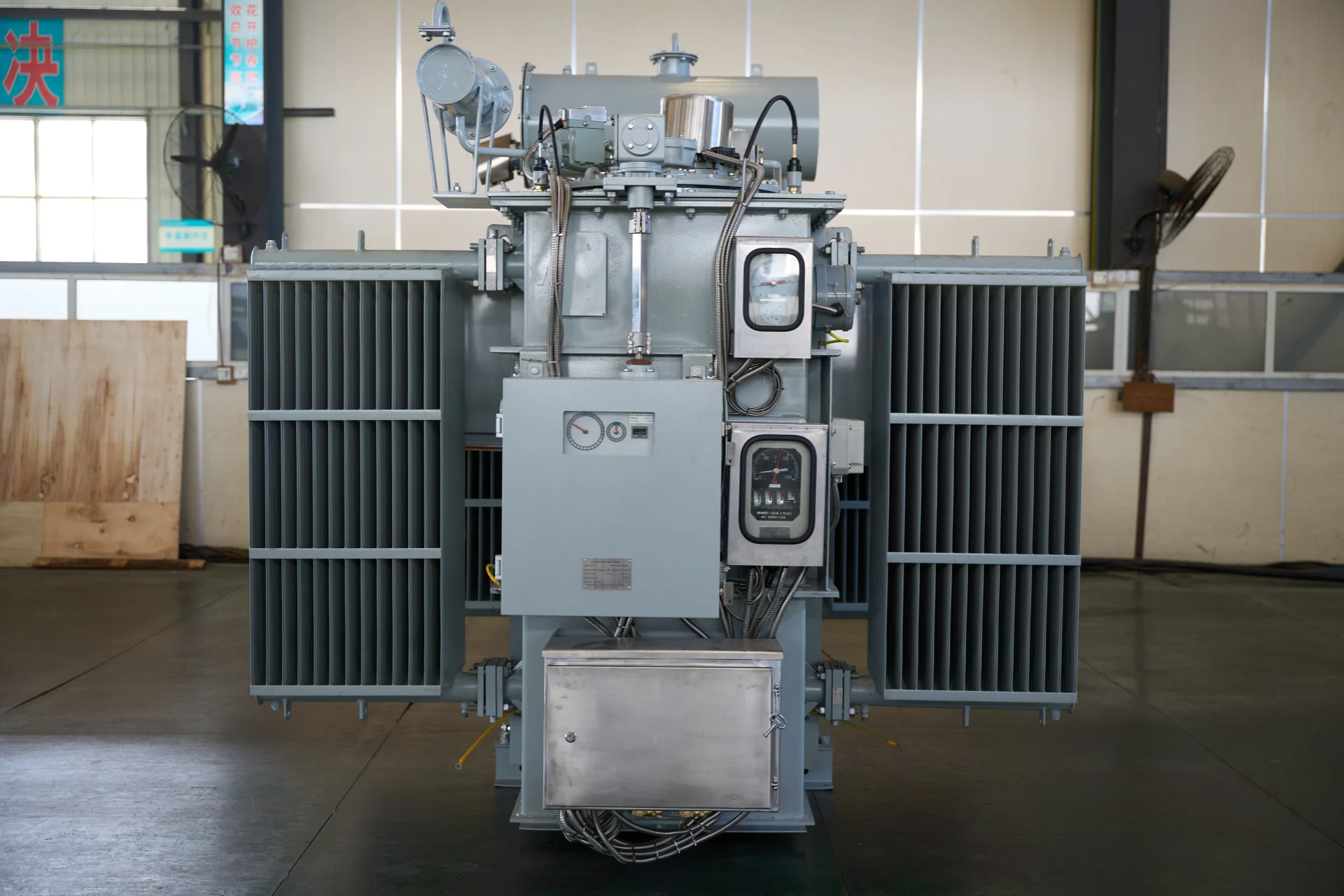

The oil-immersed power transformer, rated at 200kVA, is designed for use in substations, efficiently converting voltage. It is equipped with high-quality transformer oil, which enhances heat dissipation and prolongs the lifespan of the equipment. Ideal for various power supply applications, it excels in industrial environments requiring stable voltage and high performance.

630kVA Three-Phase Oil-Immersed Outdoor Substation Transformer | 220V to 380V Step-Up Transformer

This 630kVA three-phase oil-immersed transformer is designed for outdoor substations, providing reliable voltage conversion from 220V to 380V. With a robust oil-immersed cooling system, it ensures excellent heat dissipation, stable performance, and long service life. Ideal for industrial facilities, commercial power distribution, and utility applications, this step-up transformer delivers consistent efficiency even under heavy load conditions.

750kVA 3-Phase Oil-Immersed Outdoor Substation Transformer

A 750kVA 3-phase oil-immersed outdoor substation transformer is designed for stable and efficient power distribution in industrial, commercial, and utility applications. Built with high-quality insulation and premium transformer oil, it provides excellent cooling performance and long-term reliability. The transformer ensures accurate current measurement and voltage conversion, making it ideal for outdoor substations operating under demanding conditions.

25000kVA Oil-Immersed Copper Transformer For Substation

The 25,000kVA oil-immersed copper transformer is engineered for high-standard power distribution in large industrial facilities, utility networks, and high-voltage substations. Built with premium pure copper windings, it delivers exceptional electrical conductivity, reduced losses, and long-term operational stability. The oil-immersed cooling system ensures efficient heat dissipation, allowing the transformer to perform reliably under continuous heavy load conditions.

31500kVA 35kV Oil-Immersed Copper Transformer For Substation

The 31500kVA 35kV Oil-Immersed Copper Transformer is engineered for high-capacity, stable, and efficient power distribution across industrial plants, substations, and utility networks. Built with a high-purity copper winding structure, the transformer ensures superior conductivity, reduced losses, and long-term reliability under continuous heavy-load operation. Its oil-immersed insulation system provides excellent thermal performance, enabling stable operation even in demanding outdoor environments. The robust 35kV design enhances voltage regulation, short-circuit resistance, and overall safety. Advanced manufacturing standards, precision coil winding, and strict quality control ensure exceptional dielectric strength and mechanical durability.

40MVA 110kV Three Phase Oil Immersed Transformer for Substation

The 40MVA 110kV Three Phase Oil Immersed Transformer is engineered for reliable high-voltage transmission and distribution in substations and power plants. Featuring high-purity copper windings, advanced ONAN/ONAF cooling, and on-load tap changer (OLTC ±8×1.25%), it delivers superior efficiency and minimal no-load/loss performance (SZ11/SZ13 series). Fully compliant with IEC 60076, GB 6451, and IEEE standards, it withstands 200kV lightning impulse and offers partial discharge below 10pC. The corrugated tank design ensures optimal heat dissipation and mechanical strength in harsh environments. Ideal for 110/33kV, 110/11kV, or 110/6.3kV step-down applications. Vacuum oil filling and nitrogen sealing guarantee long-term insulation integrity. Trusted by utilities worldwide for stable, maintenance-free operation over 30+ years. Contact us for technical datasheet and competitive pricing.

42MVA 220kV Three Phase Oil Filled Transformer for Substation

The 42MVA 220kV Three Phase Oil Filled Transformer is specifically engineered for high-voltage transmission substations and utility grid applications. Featuring 99.9% electrolytic copper windings, advanced ONAN/ONAF cooling, and ±8×1.25% on-load tap changer, it ensures ultra-low no-load and load losses (SZ13 series available). Fully compliant with IEC 60076, GB/T 6451, and ANSI/IEEE standards, it successfully passes 460 kV lightning impulse, PD level below 10 pC, and induced test at 1.5Um/√3. Robust corrugated tank and conservator design provide excellent thermal and mechanical performance in extreme climates. Ideal for 220/33kV, 220/11kV, or 220/6.6kV step-down configurations. Vacuum oil processing and nitrogen blanketing guarantee long-term reliability and 35+ year service life. Trusted by national grids worldwide. Contact us for datasheet, pricing, and customization options.

250MVA 330kV High-Voltage Oil-Immersed Distribution Transformer for Grid & Substation

The 250MVA 330kV High-Voltage Oil-Immersed Distribution Transformer is engineered for reliable and efficient power transmission in large utility grids and high-demand substations. Designed with advanced insulation and a durable oil-immersed cooling system, it ensures excellent thermal stability and long service life. The high-voltage 330kV configuration provides exceptional performance in long-distance power delivery, minimizing losses and improving grid stability. Its precision-wound copper coils, high-strength core materials, and robust tank structure guarantee safe operation under fluctuating load conditions. With strong short-circuit resistance, high dielectric strength, and low noise operation, this transformer meets stringent international standards. It is widely used in national grid projects, power plants, and heavy-industry energy networks, supporting continuous, stable, and efficient power distribution.

370MVA 750kV Oil-Immersed High-Voltage Transformer for Power Transmission

The 370 MVA 750 kV Oil-Immersed High-Voltage Transformer is designed for ultra-high-voltage (UHV) power transmission systems requiring exceptional reliability, stability, and long-distance energy delivery. With a robust oil-immersed insulation structure and high-grade copper windings, this transformer offers outstanding dielectric strength, low partial discharge, and excellent thermal performance. Engineered for 750kV grid networks, it effectively reduces transmission losses, enhances voltage regulation, and ensures safe operation under demanding load variations. Its precision-built core, advanced cooling system, and reinforced tank construction enable superior efficiency, extended service life, and high short-circuit resistance. Ideal for national power grid projects, long-distance transmission corridors, high-capacity substations, and UHV interconnection systems, this transformer delivers consistent and secure performance in critical large-scale power infrastructures.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, transformers exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High-efficiency Core Design

High magnetic permeability and low loss silicon steel sheets are used and processed by special process to reduce hysteresis loss and eddy current loss and improve conversion efficiency.

Multiple Protection Systems

IP65 protection grade design combines multiple protection measures such as anti-corrosion, anti-UV, anti-condensation and anti-small animal intrusion.

Ultra-low Noise Technology

A special shock-absorbing structure, low-noise fans, and optimized heat dissipation design ensure operating noise is far below industry standards.

Intelligent Cooling System

The heat dissipation system with adaptive temperature control automatically adjusts the heat dissipation efficiency according to the load and ambient temperature to reduce energy consumption.

Safety Wiring System

Insulated protective cover and anti-misoperation design ensure personnel safety during installation and maintenance and reduce accident risks

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

Substation Transformers have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Seismic Resistance Level

IEC 60068-2-57

Suitable for earthquake-prone areas

Altitude

≤3000m

More than special design

Why Choose Us

Reliability for Critical Grid Operations

Substation Transformers Manufacturer

We manufacture a wide range of power transformers and distribution transformers, including oil-immersed substation transformers built to meet IEC, IEEE, and ANSI standards. With advanced production technology, strict quality testing, and customized voltage configurations, NPC Electric ensures stable operation, minimal energy loss, and long service life. As a professional substation transformer manufacturer, we are committed to delivering dependable products and technical support to customers worldwide.

Exceptional Efficiency & Energy Conservation

Robust Design for Harsh Environments

Product Show

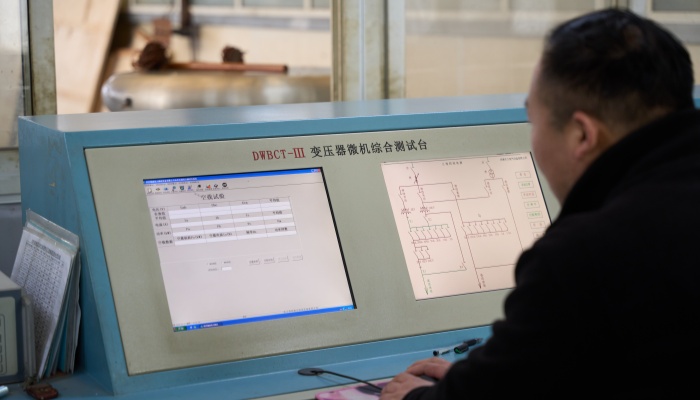

Testing and Certification

Bare Cable Test Report

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

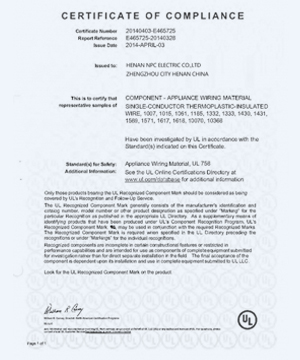

UL Laboratory Certificate

UL Product Certificate

Project Cases

Project Cases

CompletedProvide stable and reliable power conversion solutions for the smart factory to meet diverse production needs.

Country:Mexico

Model:220kVA Substation Transformer x 2

Guyana Power & Light Inc

CompletedEnsure the power safety of surrounding residents and meet daily work needs

Country:Guyana

Model:13.8kV - 0.48Y/0.22kV, 3MVA Substation Transformer x 5

Surinam Factory

CompletedNPC transformers provide safe, efficient, and reliable power distribution in Surinam.

Country:Surinam

Model:750VA Substation Transformer x 5

Related Articles

Technical Advantages

FAQ From Customers

-

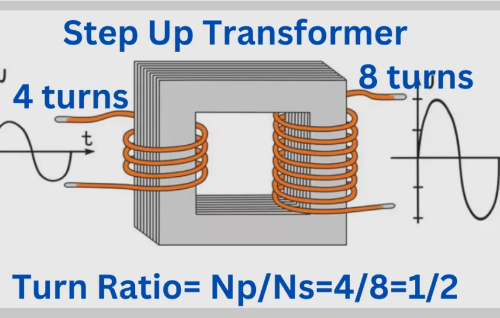

What is a substation transformer?

A substation transformer is a critical component in an electrical substation that steps voltage up or down between transmission and distribution systems. It allows efficient power transfer from high-voltage transmission lines to lower-voltage distribution transformers used in residential, commercial, and industrial applications. Most substation transformers are designed as oil immersed transformers for better cooling and insulation performance. -

How many transformers are in a substation?

The number of transformers in a substation depends on its size, capacity, and network design. A small distribution substation may have one or two substation transformers, while large power substations can include multiple units operating in parallel to handle higher load demands. Redundancy is often built in to ensure reliable power supply during maintenance or peak demand. -

What are the four types of transformers?

The four main types of transformers used in power systems are:

1. Power transformers – for high-voltage transmission networks.

2. Distribution transformers – for local energy distribution.

3. Instrument transformers – for measurement and protection.

4. Isolation transformers – for safety and equipment protection.

Among these, oil-immersed transformers are the most common type used in substation transformer design due to their high efficiency and durability. -

Why do we need a substation transformer?

A substation transformer is essential for voltage regulation and safe power transmission. It converts high-voltage electricity from transmission lines to lower levels that can be distributed through distribution transformers to consumers. Without substation transformers, energy losses during long-distance transmission would increase dramatically, reducing overall grid efficiency and reliability. -

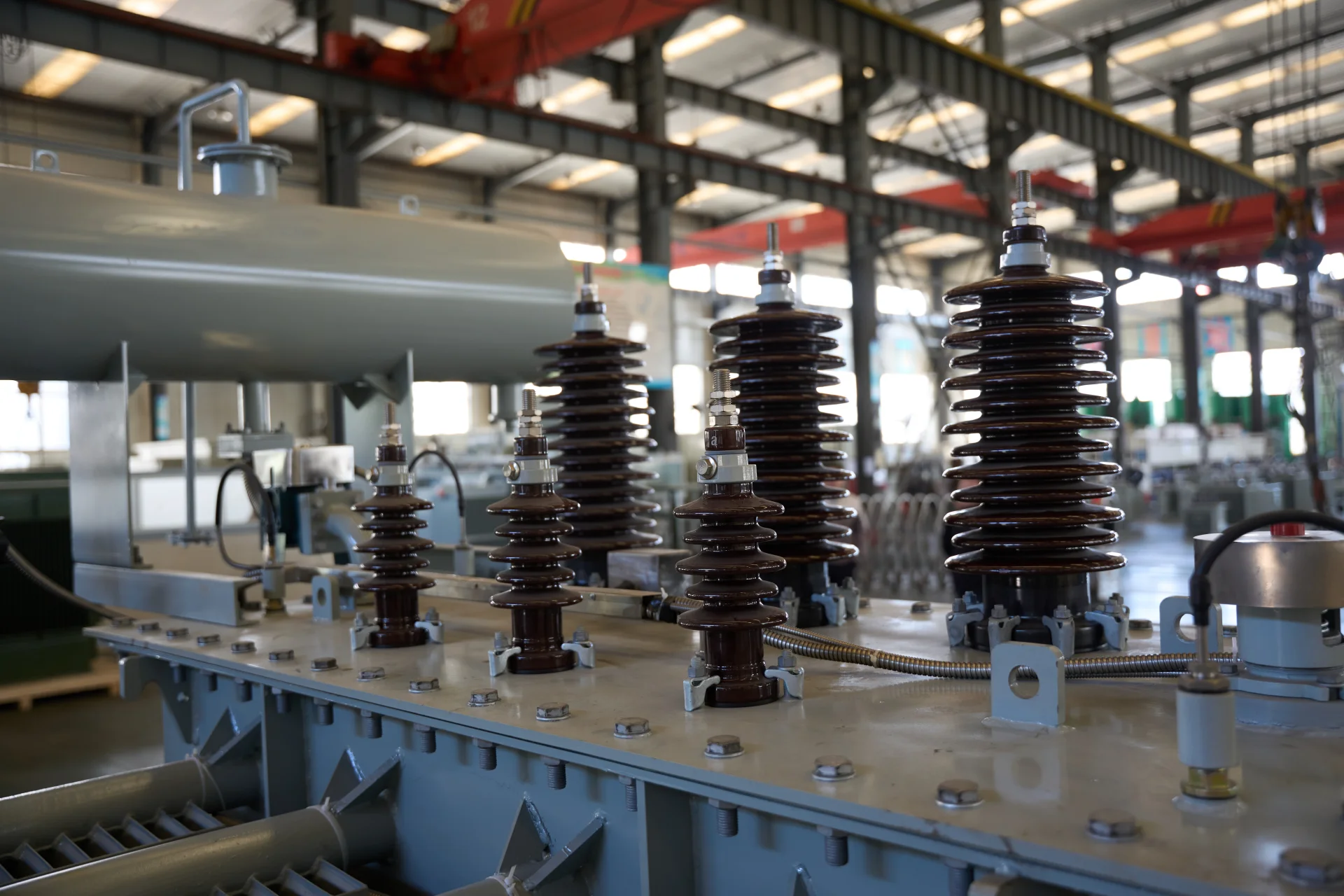

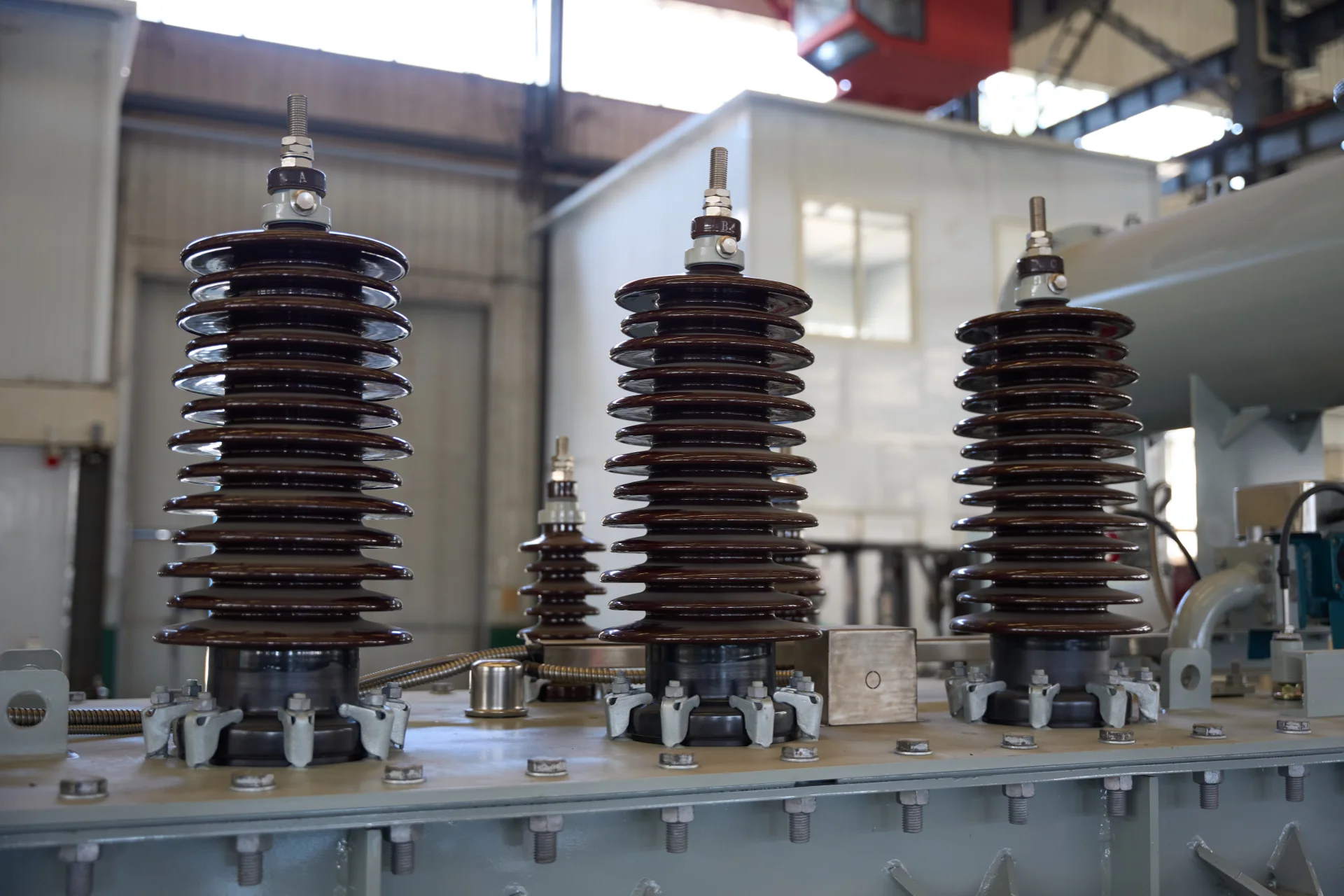

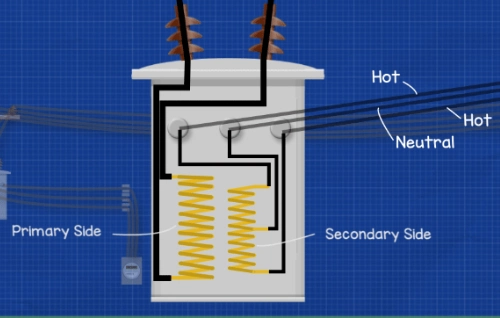

What is inside a substation transformer?

Inside a substation transformer, you’ll find a magnetic core, primary and secondary windings, insulating oil, bushings, and a cooling system. The oil immersed design helps regulate temperature and prevent electrical faults by providing insulation and heat dissipation. This internal structure ensures safe, stable, and efficient performance under high-voltage operating conditions in modern electrical substations.