AI robots in industrial manufacturing

In recent years, AI robots in industrial manufacturing have revolutionized production by transforming traditional workflows into highly automated, intelligent operations. As part of the broader move toward smart factories and Industry 4.0, robotic systems powered by artificial intelligence (AI) are playing an increasingly vital role in streamlining production processes, increasing productivity, and enhancing overall operational efficiency.

The Rise of AI-Driven Robotic Systems

At the heart of this transformation is the integration of AI-driven capabilities into industrial robots. Unlike earlier generations of automation that followed rigid programming, modern AI robots can learn, adapt, and make real-time decisions using technologies such as machine learning, computer vision, and predictive analytics.

These advancements have enabled robots to handle complex tasks on assembly lines with a level of precision and speed that outpaces traditional methods. AI not only improves robot functionality but also enhances coordination between machines and human workers, creating a more flexible and responsive manufacturing environment.

Increasing Productivity and Reducing Downtime

One of the most compelling benefits of AI robots is increasing productivity. By automating repetitive or time-consuming jobs, manufacturers can produce more in less time, with fewer errors. For example, robots equipped with vision systems can identify and correct defects instantly, reducing the need for manual quality checks.

Additionally, AI supports predictive maintenance, a technique that uses sensor data and analytics to foresee equipment failures before they happen. This proactive approach helps in reducing downtime, preventing costly interruptions in the manufacturing process.

Precision and Flexibility: Selective Compliance Assembly Robot Arms

A standout example of AI in robotics is the Selective Compliance Assembly Robot Arm (SCARA). These robots are particularly suited for high-speed, precise tasks such as assembling small components. Thanks to AI, SCARA systems can adapt to minor variations in parts or conditions without manual reprogramming, offering both accuracy and flexibility.

Enhancing Efficiency and Reducing Waste

AI robots contribute to increased efficiency not just through speed, but also through optimization. By continuously analyzing data, AI can fine-tune robotic movements, reduce energy consumption, and minimize material use. This data-driven approach plays a critical role in reducing waste, improving sustainability, while lowering operational costs.

Human-Robot Collaboration

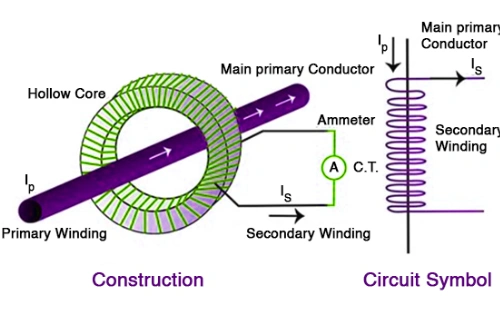

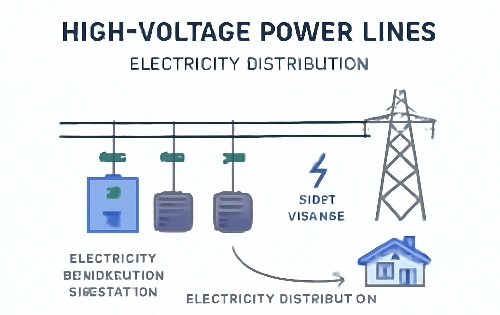

Rather than replacing humans, many AI robots are designed to work alongside humans. These collaborative robots, or "cobots", support workers by handling dangerous, dirty, or dull tasks, allowing humans to focus on roles that require critical thinking and creativity. This synergy between humans and machines enhances workplace safety and satisfaction. At the same time, we need to conduct rigorous testing on the transformer product to ensure the efficiency and quality of the AI robot in the production process.

The Future of AI robots in industrial manufacturing

Looking forward, the role of AI robots in manufacturing will continue to evolve. With continuous improvements in machine learning, robotic systems will become even more intuitive, capable of self-optimization and real-time learning. In the context of smart factories and Industry 4.0, these intelligent machines will connect with other digital systems, forming a cohesive, agile, and responsive manufacturing network.

The integration of AI-driven robotic systems in industrial manufacturing marks a pivotal shift toward smarter, more adaptive operations. From selective compliance assembly robot arms to advanced vision systems and predictive maintenance, these innovations are increasing productivity, reducing downtime, and creating more sustainable production environments. As AI continues to advance, its collaboration with human workers will shape the future of manufacturing—one where robots work not to replace, but to empower.

3GHSSYCY-mining-cable-2.webp)