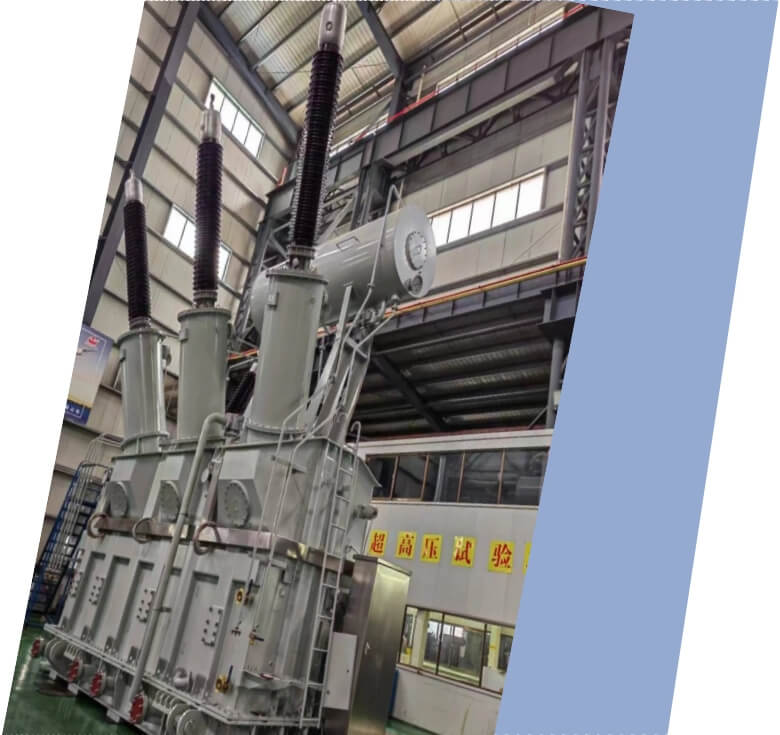

65kV Three-Phase Oil-Immersed Power Transformer with No-Load Voltage Regulation

- Primary Voltage Ratings 69kV 66kV 65kV or others

- Secondary Voltage Ratings 33/13.8/11 kV or customized

- H.V. Tap Range ±8×1.25% or others

- Type Oil-immersed power transformer

- BIL Up to 350kV

- Standards IEEE, ANSI, IEC, CSA

- Application high voltage power distribution networks, public power systems, industrial power stations

- Power Rating 100 - 1000kVA

- Certificate UL ,CESI ,ISO

- Cooling Method ONAN/ ONAF

- Opeartion Step Down & Step Up

Technical Specifications

| Rated Power | 100 - 1000kVA |

| Rating Primary Voltage | 69kV 66kV 65kV or others |

| Secondary Voltage |

33kV 13.8kV 11kV Customized |

| Frequency | 50/60Hz |

| Vector Group | Dyn11, YNd1, Dyn1, YNd11 or others |

| Winding Material | Aluminum/Copper |

| Efficiency | As IEEE, CAS Std or Customized |

| Impedance Voltage | As IEC |

| Altitude | ≤1,000m or Customized |

| Enclosure material | Mid Steel |

| HV Bushing |

| LV Bushing |

| OLTC/NLTC |

| Lifting hook for complete transformer |

| Name plate |

| Oil temperature |

| Winding temperature |

| Radiators |

| Oil level |

| Pressure relief valve |

| CT |

Customization Optional

Packing and Shipping

For main-body protection, the transformer is securely anchored to a heavy-duty steel frame or export-grade wooden pallet. Shock-absorbing pads and structural braces are placed at critical points to prevent vibration, shifting, or impact damage during transit. To protect against weather exposure, the entire unit is wrapped with multi-layer waterproof coverings, UV-resistant sheets, and protective corner guards. Oil valves are sealed, and optional nitrogen-filled protection can be added for long-distance shipping or high-humidity destinations.

For international shipments, we offer containerization, flat-rack solutions, and break-bulk loading depending on transformer size and route requirements. All packaging materials meet ISPM-15 fumigation standards for global customs compliance. Detailed packing lists, quality certificates, FAT reports, manuals, and accessory inventories are included in waterproof documentation envelopes fixed to the transformer body.

The logistics team coordinates directly with professional carriers to manage loading, route planning, customs documentation, and final delivery arrangements. Upon arrival, on-site engineers can support unloading, inspection, and installation guidance if required. The entire packing and shipping workflow is designed to maintain the mechanical integrity and performance reliability of the transformer until it reaches the operational site.

Manufacturer Test

Progress test

The Progress Test for the 65kV Three-Phase Oil-Immersed Power Transformer with No-Load Voltage Regulation is performed at key manufacturing stages to ensure that every component meets design and quality requirements before moving to the next production phase. This test program includes detailed inspections of raw materials such as silicon steel laminations, copper windings, insulation paper, and transformer oil to confirm compliance with technical specifications. During coil winding and core assembly, dimensional accuracy, winding tension, insulation layering, and mechanical fastening are carefully examined. Partial discharge checks and insulation strength evaluations are conducted on subassemblies to detect early faults. As the transformer tank is manufactured, welding seams, pressure resistance, vacuum tightness, and surface treatment quality are tested. Before final assembly, the active part undergoes pre-impregnation and vacuum drying to ensure moisture-free insulation.

Design Tests

All transformers will be tested after finishing the production test items as follows:

♦ Leak testing with pressure for liquid-immersed transformers

♦ Test of transformer oil

♦ Measurement of voltage ratio and check of phase displacement

♦ Measurement of winding DC resistance

♦ Capacitive bushing test

♦ Operation test on on-load tap-changer

♦ Measurement of short-circuit impedance and load loss

♦ Lightning impulse test

♦ Induced-voltage test with partial discharge measurement

♦ Auxiliary wiring check

♦ Current transformer test

♦ Frequency response analysis test

Transformer Factory Acceptance Test

The Factory Acceptance Test for the 65kV Three-Phase Oil-Immersed Power Transformer with No-Load Voltage Regulation is conducted after full assembly to verify compliance with design specifications and international standards. The FAT includes key electrical routine tests such as winding resistance measurement, ratio and vector group verification, insulation resistance testing, and polarity checks. Performance tests include no-load loss, load loss, impedance measurement, and applied and induced voltage withstand tests. Lightning impulse tests are performed to ensure dielectric strength, while partial discharge measurements confirm insulation quality. Mechanical inspections cover tank pressure integrity, bushing alignment, tap changer operation, oil quality analysis, and verification of all protection devices and accessories. All results are reviewed with the customer to ensure the transformer meets operational, safety, and reliability requirements before shipment.

Routine Test - Impulse Tests

Voltage divider (used to measure impulse voltage waveform, resistor divider or capacitor divider)

Oscilloscope (used to record impulse waveform, common brands such as Tektronix, Keysight)

Calibrate and check the impulse voltage generator, measurement system, and control system to ensure that the instruments and equipment are in good condition and meet the test standards.

Connect the impulse voltage generator correctly to each winding terminal (high voltage terminal, ground terminal) of the device under test, and ensure that all test instruments are well grounded.

Apply Test Voltage:

Select the appropriate impulse voltage waveform and amplitude according to the rated voltage of the equipment

Front Time

Time to Half-Value

Peak Voltage

Distortion

Ambient temperature and humidity (especially when the test environment needs to be corrected)

If the waveform deviation is too large, adjust the impulse generator parameters and reapply the test.

In special cases, inter-winding impact, voltage-to-ground impact or coil corner impact are performed (according to the test plan).

Waveforms are stable and meet standard specifications.

Waveform variations between repeated tests are minimal (usually good waveform overlap with no noticeable abnormal excursions).

Application

Technical Advantages

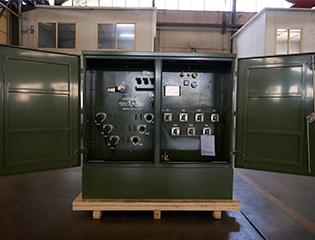

Product Packaging

Related Products

FAQ From Customers

-

What is a Transformer?A transformer is an electrical device used to change the voltage of alternating current (AC). It works on the principle of electromagnetic induction, converting high-voltage current into low-voltage current or low-voltage current into high-voltage current. Transformers are widely used in power transmission, distribution systems, and various electronic devices.

-

What are the main uses of a transformer?The main use of a transformer is voltage conversion. Transformers are used in power transmission systems to help transfer electricity from power plants to consumers. In addition, transformers are also used in electronic devices such as chargers, televisions, power adapters, etc., to adjust the voltage to meet the requirements of different devices.

-

Do you have UL listed?Yes, our transformer has UL listed. We have exported to America many pad mounted transformer,substation transformer and HV.