How to Choose the Right Wires and Cables?

Selecting the right electrical wire and cable is crucial for ensuring safety, efficiency, and reliability in any electrical project. Whether you're wiring a home, upgrading industrial equipment, or tackling a DIY project, understanding the specifications of cables and wires—like 10/3 wire, 4/0 aluminum wire, or bare conductor options—can make all the difference. This guide explores key factors to consider when choosing electrical wire and cable, helping you match your selection to the requirements of your application while prioritizing safety and performance.

Why Choosing the Right Electrical Wire and Cable Matters

Electrical wire and cable serve as the backbone of any electrical system, carrying power from one point to another. Using the wrong type can lead to inefficiencies, overheating, or even fire hazards. Factors like voltage rating, insulation material, and high temperature tolerance play a significant role in determining which cables and wires are suitable for your needs. By understanding these elements, you can select products like 10/3 wire or bare conductor cables that meet safety standards and perform reliably.

Key Factors to Consider When Choosing Wires and Cables

To choose the right electrical wire and cable, evaluate the following factors based on your project’s specific requirements.

1. Understand the Voltage Rating

The voltage rating of cables and wires indicates the maximum voltage they can safely handle. For example, a 10/3 wire—commonly used for heavy appliances like dryers or ranges—typically has a voltage rating of 600V and is designed for 30-amp circuits. In contrast, 4/0 aluminum wire is often used for high-power applications, such as service entrance cables, with ratings suitable for 200-amp services.

Always check the requirements of your application to ensure the wire’s voltage rating matches or exceeds the system’s demands. Using a wire with an insufficient rating can cause overheating or failure, while over-specifying can increase costs unnecessarily.

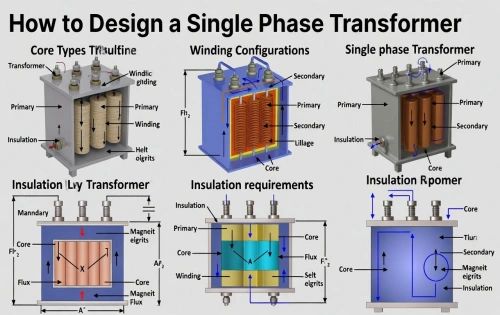

2. Choose the Right Insulation Material

The insulation material protects electrical wire and cable from environmental factors, such as moisture, heat, or chemicals. Common insulation types include:

- Thermoplastic insulation (e.g., PVC): Found in 10/3 wire, it’s flexible, cost-effective, and suitable for general indoor use.

- Thermoset insulation (e.g., XLPE): Offers better resistance to high temperatures and is ideal for outdoor or industrial applications.

- Rubber or silicone: Used in environments requiring flexibility and high temperature tolerance.

For outdoor or underground installations, select cables and wires with UV-resistant or waterproof insulation. If your project involves extreme heat, such as near furnaces, opt for high-temperature-rated insulation to ensure longevity.

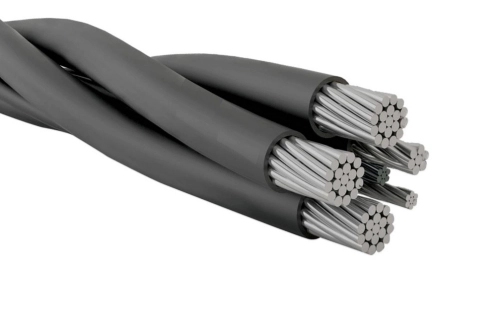

3. Consider the Conductor Type

The conductor is the metal core of electrical wire and cable that carries electricity. Common conductor materials include copper and aluminum, each with distinct properties:

- Copper: Highly conductive, flexible, and corrosion-resistant, making it ideal for 10/3 wire and most residential applications.

- Aluminum: Lightweight and cost-effective, used in 4/0 aluminum wire for high-power, long-distance runs like service entrances.

- Bare conductor: These uninsulated wires, often made of copper or aluminum, are used in grounding systems or overhead power lines where insulation isn’t required.

Choose a bare conductor for grounding or specific industrial applications, but ensure it’s installed safely to avoid accidental contact. For general wiring, insulated cables and wires like 10/3 wire are safer and more versatile.

4. Pay Attention to Wire Size and Gauge

Wire size, measured in American Wire Gauge (AWG), determines how much current electrical wire and cable can carry. Smaller AWG numbers indicate thicker wires capable of handling higher currents. For instance:

- 10/3 wire: A 10-gauge wire with three conductors (plus a ground), suitable for 30-amp circuits powering appliances.

- 4/0 aluminum wire: A much thicker wire (0000 AWG) used for 200-amp services or heavy industrial loads.

Match the wire gauge to the amperage and length of your circuit. Longer runs require thicker wires to minimize voltage drop. Consult the National Electrical Code (NEC) or a professional to ensure compliance with the requirements of your application.

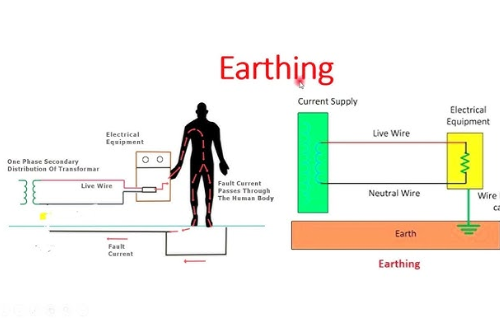

5. Use Color-Coded Wires for Safety

Color-coded insulation simplifies installation and enhances safety by indicating a wire’s purpose. Standard color codes in the U.S. include:

- Black, red, or blue: Hot (live) wires, as seen in 10/3 wire.

- White or gray: Neutral wires.

- Green or bare: Ground wires, often a bare conductor.

Using color-coded cables and wires reduces the risk of miswiring, which can lead to electrical faults. Always follow local codes when selecting electrical wire and cable to ensure proper identification.

6. Evaluate Environmental Conditions

The environment where cables and wires will be installed affects your choice. Consider factors like:

- High temperature: Use thermoplastic insulation or thermoset materials rated for heat exposure.

- Moisture: Opt for cables with water-resistant insulation for outdoor or damp locations.

- Physical stress: Choose electrical wire and cable with durable jackets for areas prone to abrasion or impact.

For example, 4/0 aluminum wire used in outdoor service entrances often has weather-resistant insulation, while bare conductor cables may be suitable for overhead lines exposed to the elements.

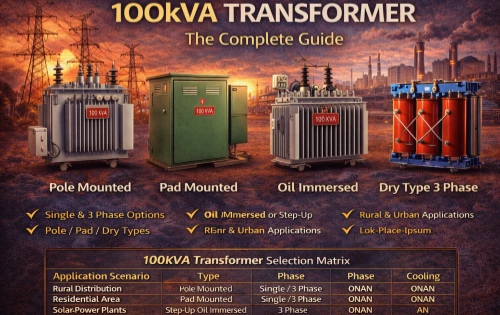

7. Match Wires to the Application

Different projects have unique requirements of your application. Here are common scenarios and recommended cables and wires:

- Residential wiring: 10/3 wire is ideal for heavy appliances, while 12/2 or 14/2 wires suit lighting and outlets.

- Service entrances: 4/0 aluminum wire is commonly used for high-amperage connections to the main panel.

- Grounding: Bare conductor cables are cost-effective for grounding rods or systems.

- Industrial settings: Choose electrical wire and cable with robust insulation for high-power machinery or high temperature environments.

Always verify load requirements, circuit length, and local codes before selecting cables and wires.

Common Types of Electrical Wire and Cable

Understanding popular types of electrical wire and cable can guide your decision:

- NM-B (Romex): Non-metallic sheathed cable, like 10/3 wire, used for indoor residential wiring.

- UF-B: Underground feeder cable with waterproof insulation for outdoor use.

- THHN/THWN: Single-conductor wires with thermoplastic insulation, versatile for conduit installations.

- Service entrance cable: Heavy-duty cables like 4/0 aluminum wire for connecting to utility lines.

- Bare conductor: Uninsulated wires for grounding or overhead applications.

Each type is designed for specific requirements of your application, so choose accordingly.

Safety Tips for Choosing and Installing Wires and Cables

- Consult a professional: If unsure, hire a licensed electrician to select and install electrical wire and cable.

- Follow codes: Adhere to NEC and local regulations for safe installation.

- Avoid overloading: Ensure the wire gauge and voltage rating match the circuit’s demands.

- Inspect regularly: Check cables and wires for wear, especially in high-temperature or outdoor settings.

Choosing the right electrical wire and cable requires careful consideration of voltage rating, insulation material, conductor type, and environmental factors. By matching cables and wires to the requirements of your application, you ensure safety, efficiency, and compliance with electrical standards. Whether for residential, commercial, or industrial use, understanding color-coded systems, high temperature tolerance, and thermoplastic insulation empowers you to make informed decisions for any project.