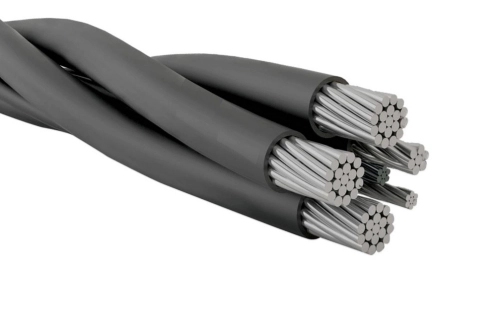

Wires and Cables

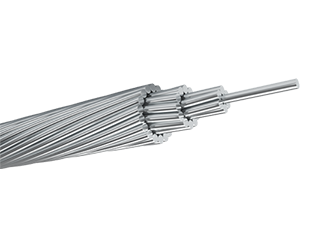

AAAC

ALL ALUMINUM ALLOY CONDUCTORS(AAAC)

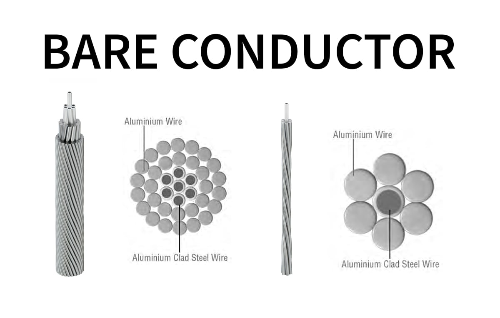

All Aluminum alloy (ALMELEC) electrical wire conductors are made from high-strength Aluminum-Magnesium-Silicon alloy. These conductors boast a superior strength-to-weight ratio compared to standard AAC, allowing for longer spans and reduced support structures in challenging terrains. Their improved sag characteristics minimize clearance issues, while excellent corrosion resistance extends service life in aggressive environments like marine or polluted zones. Electrically, AAAC offers lower power losses and better conductivity, optimizing energy efficiency in distribution networks. Manufactured to standards such as IEC 61089 and ASTM B399, they feature concentric stranding for mechanical stability and ease of installation with simpler fittings than ACSR. Versatile in size from small distribution lines to high-voltage transmission, AAAC supports applications on poles, towers, and substations. By reducing maintenance and enhancing reliability, these conductors provide a sustainable, cost-efficient alternative for modern power infrastructure, contributing to greener energy systems worldwide. Their lightweight design also facilitates easier handling during setup.

AAAC Dog Conductor Cable

AAAC DOG conductor is an All Aluminum Alloy Conductor manufactured according to ASTM B399 or IEC 61089 standards, offering high strength, good conductivity, and excellent corrosion resistance.The Dog-size AAAC conductor offers improved sag characteristics and mechanical stability, making it suitable for longer spans and areas exposed to coastal, industrial, or high-humidity environments. Its homogeneous aluminum alloy construction eliminates galvanic corrosion risk and reduces maintenance requirements over long service life. Produced in accordance with ASTM and IEC standards, the AAAC Dog Conductor Cable ensures consistent quality, uniform stranding, and reliable performance. It is widely selected for modern utility networks where efficiency, durability, and lifecycle cost optimization are critical.

AAAC Moose Conductor Cable

AAAC MOOSE conductor is manufactured in compliance with ASTM B399 or IEC 61089 standards, using high-strength aluminum alloy 6201-T81 for enhanced conductivity and corrosion resistance. Constructed entirely from high-strength aluminum alloy strands, it offers superior mechanical strength and corrosion resistance compared with traditional aluminum conductors. The Moose-size AAAC conductor is particularly suitable for long-span installations, providing excellent sag control and stable operation under heavy mechanical loads. Its all-alloy design ensures uniform conductivity and eliminates steel-related corrosion issues, extending service life in harsh environmental conditions. Manufactured under strict quality management systems, the AAAC Moose Conductor Cable complies with international standards and delivers reliable performance, simplified installation, and reduced lifecycle costs for utility and infrastructure projects worldwide.

AAAC Panther Conductor Cable

AAAC PANTHER Conductor is a premium-grade All Aluminum Alloy Conductor engineered for reliable performance in overhead distribution and sub-transmission lines. Compliant with ASTM B399, IEC 61089, and BS EN 50182 standards, this conductor is manufactured using high-strength 6201-T81 aluminum alloy, offering excellent conductivity, enhanced tensile strength, and superior corrosion resistance. Compared with traditional AAC conductors, the Panther-size AAAC conductor provides higher tensile strength and reduced sag, making it suitable for longer spans and higher mechanical loading conditions. Its all-aluminum alloy construction eliminates steel reinforcement, effectively preventing galvanic corrosion and improving long-term reliability, especially in coastal, humid, and industrial environments. Produced in accordance with IEC and ASTM standards, the AAAC Panther Conductor Cable ensures uniform strand geometry, stable resistance values, and consistent performance throughout its service life. It is widely selected by utilities seeking lower maintenance costs, improved line efficiency, and enhanced durability for modern overhead power networks.

AAAC Rabbit Conductor Cable

AAAC RABBIT conductor is a compact, high-performance All Aluminum Alloy Conductor manufactured using 6201-T81 aluminum alloy, in compliance with ASTM B399, IEC 61089, and BS EN 50182 standards. Named "Rabbit" for its 50 mm² nominal area with 7-strand configuration, it offers superior conductivity (61% IACS) and tensile strength (295 MPa min) compared to ACSR. Made from heat-treated aluminum-magnesium-silicon alloy (6201-T81), this cable provides excellent corrosion resistance, low weight, and reduced sag for longer spans. Compliant with ASTM B398, B399, IEC 61089, and BS EN 50182 standards, it supports voltages up to 33kV with ampacity up to 250A at 75°C. The homogeneous alloy construction eliminates bimetallic corrosion and ensures uniform mechanical properties. The AAAC Rabbit Conductor Cable minimizes line losses, withstands harsh weather, and requires minimal maintenance. Ideal for rural electrification, urban upgrades, and renewable energy integrations, it delivers reliable, cost-effective power delivery in overhead lines worldwide, outperforming traditional conductors in corrosive or coastal environments.

ALLIANCE AAAC Conductor Cable

ALLIANCE AAAC (All Aluminum Alloy Conductor) cables are manufactured in strict compliance with international standards such as ASTM B399, IEC 61089, and BS EN 50182, making them a high-performance and reliable overhead power transmission and distribution solution. Meeting ASTM B398, B399, IEC 61089, and BS EN 50182 standards, this cable handles ampacity up to 350A at 75°C and voltages up to 33kV. The all-alloy construction avoids bimetallic corrosion, providing better resistance in harsh conditions than ACSR. Reduced weight minimizes sag and installation expenses, supporting longer spans. The Alliance AAAC Conductor Cable delivers low electrical losses, high mechanical endurance, and excellent weather tolerance. Flame-retardant variants available. Perfect for urban grids, renewable projects, and coastal setups, it provides cost-effective, low-maintenance power delivery in overhead applications globally, excelling in reliability and lifespan over conventional conductors.

AMES AAAC Conductor Cable

AMES AAAC (All Aluminum Alloy Twisted) cables comply with ASTM B399 standards and have excellent conductivity and corrosion resistance. With 250 mm² nominal area and 19-strand design, it uses heat-treated aluminum-magnesium-silicon alloy (6201-T81) for enhanced strength (295 MPa min) and conductivity (53% IACS min). Meeting ASTM B398, B399, IEC 61089, and BS EN 50182 standards, this cable handles ampacity up to 600A at 75°C and voltages up to 33kV. The all-alloy construction avoids bimetallic corrosion, providing better resistance in harsh conditions than ACSR. Reduced weight minimizes sag and installation expenses, supporting longer spans. The Ames AAAC Conductor Cable delivers low electrical losses, high mechanical endurance, and excellent weather tolerance. Flame-retardant variants available. Perfect for urban grids, renewable projects, and coastal setups, it provides cost-effective, low-maintenance power delivery in overhead applications globally, excelling in reliability and lifespan over conventional conductors.

AMHERST AAAC Conductor Cable

AMHERST AAAC (All Aluminum Alloy Conductor) cables comply with ASTM B399 standards and offer high strength, good conductivity, and excellent corrosion resistance. With 300 mm² nominal area and 37-strand design, it uses heat-treated aluminum-magnesium-silicon alloy (6201-T81) for enhanced strength (295 MPa min) and conductivity (53% IACS min). Meeting ASTM B398, B399, IEC 61089, and BS EN 50182 standards, this cable handles ampacity up to 700A at 75°C and voltages up to 33kV. The all-alloy construction avoids bimetallic corrosion, providing better resistance in harsh conditions than ACSR. Reduced weight minimizes sag and installation expenses, supporting longer spans. The Amherst AAAC Conductor Cable delivers low electrical losses, high mechanical endurance, and excellent weather tolerance. Flame-retardant variants available. Perfect for urban grids, renewable projects, and coastal setups, it provides cost-effective, low-maintenance power delivery in overhead applications globally, excelling in reliability and lifespan over conventional conductors.

AZUSA AAAC Conductor Cable

AZUSA AAAC (All Aluminum Alloy Conductor) cables comply with ASTM B399 standards and are characterized by high strength, excellent conductivity, and superior corrosion resistance. Meeting ASTM B398, B399, IEC 61089, and BS EN 50182 standards, this cable handles ampacity up to 900A at 75°C and voltages up to 33kV. The all-alloy construction avoids bimetallic corrosion, providing better resistance in harsh conditions than ACSR. Reduced weight minimizes sag and installation expenses, supporting longer spans. The Azusa AAAC Conductor Cable delivers low electrical losses, high mechanical endurance, and excellent weather tolerance. Flame-retardant variants available. Perfect for urban grids, renewable projects, and coastal setups, it provides cost-effective, low-maintenance power delivery in overhead applications globally, excelling in reliability and lifespan over conventional conductors.In-Depth Analysis

Comparative Analysis of Efficiency and Loss

Compared to the industry average, aaac cables exhibit lower losses and higher efficiency across the entire load range.

Load Efficiency Comparison(%)

No-load Loss Comparison(W)

High Conductivity Design

High-purity oxygen-free copper or high-quality aluminum conductors are used with smooth surface and low resistance to ensure efficient power transmission and reduce energy loss.

Insulation Protection System

Use flame-retardant, wear-resistant and corrosion-resistant polymer insulation materials to meet the safe operation requirements in different environments.

Weather-Resistant & Durable Technology

The outer sheath is made of UV-resistant, heat-resistant, and oil-resistant materials, making it suitable for high and low temperatures, humidity, and long-term outdoor use.

Safe Flame Retardant System

The multi-layered flame-retardant structure effectively slows the spread of flames and releases low-smoke, halogen-free gases during combustion, reducing secondary hazards.

Easy Installation & Maintenance

The flexible core and flex-resistant outer sheath provide a small bend radius and high installation efficiency. Color coding and length markings reduce installation and maintenance costs.

Intelligent Monitoring

An optional remote monitoring system is available to monitor operating status, temperature, load and other parameters in real time, and supports fault warning and remote diagnosis.

Environmental Adaptability Analysis

AAAC cables have been rigorously tested and can operate stably under various harsh environmental conditions.

Temperature Range

-40℃ ~ +55℃

Can work normally in extreme high and low temperature environments

Humidity Adaptation

0 ~ 100% RH

Including condensation environment, no frost requirement

Weather Resistance Grade

UV/IEC 60811-501

The outer sheath has excellent UV resistance and aging resistance

Chemical Corrosion Resistance

Oil / Acid / Alkali

Resistant to oil, acid, alkali and some chemical corrosion environments

Why Choose Us

Corrosion Resistance for Demanding Environments

Enhanced Strength-to-Weight Ratio & Reduced Sag

Excellent Conductivity & Energy Efficiency

Low Maintenance & Long Operational Lifespan

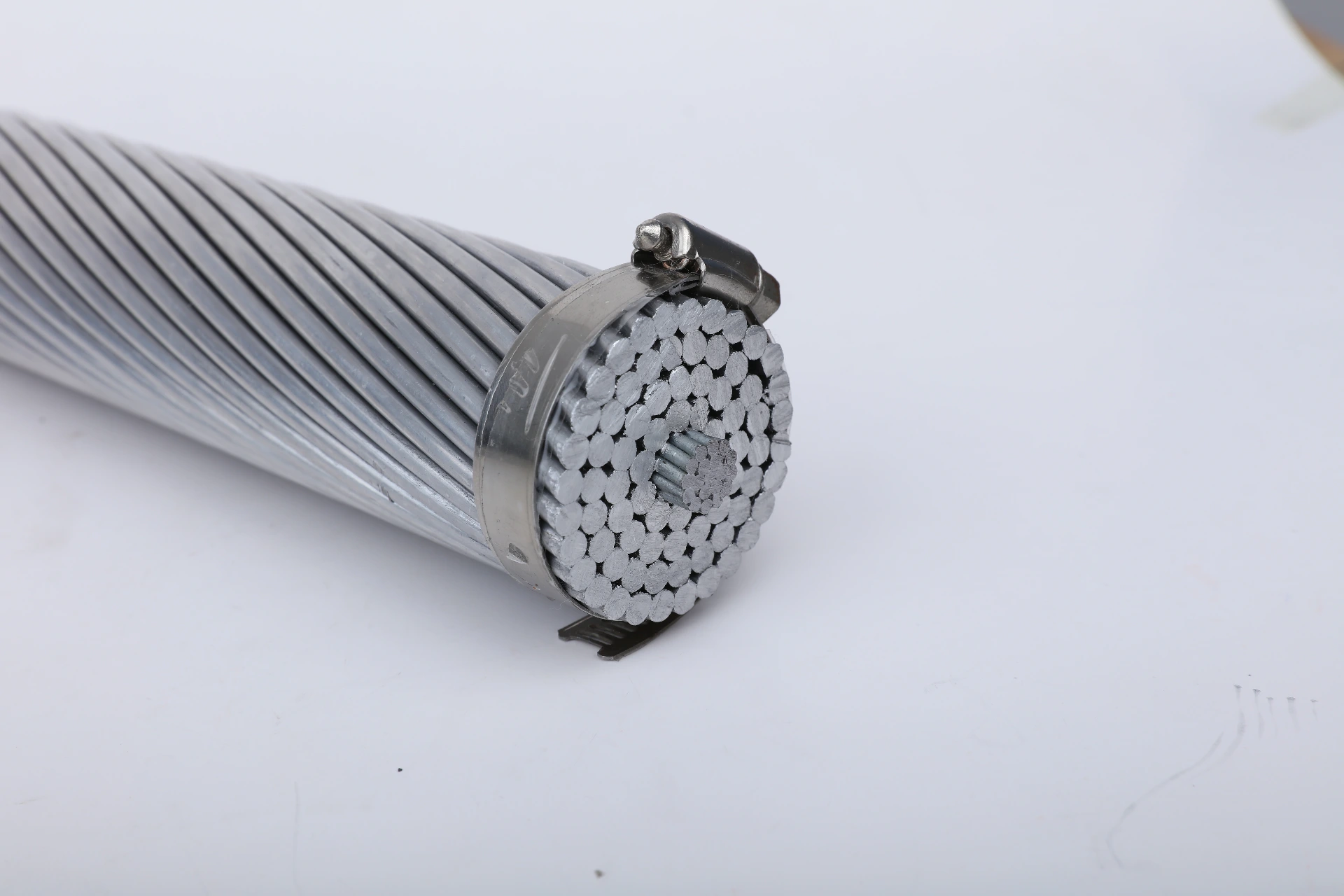

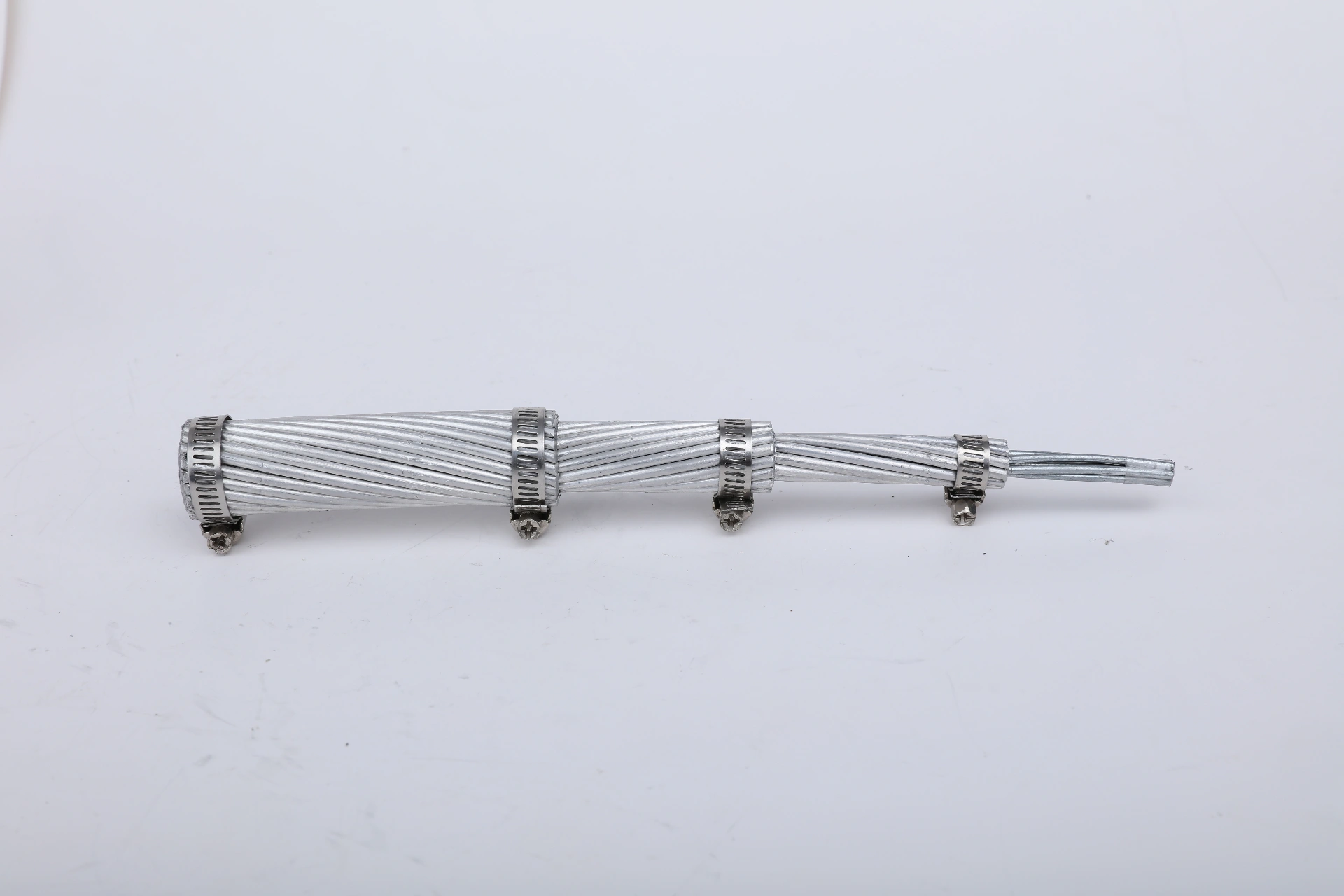

Product Show

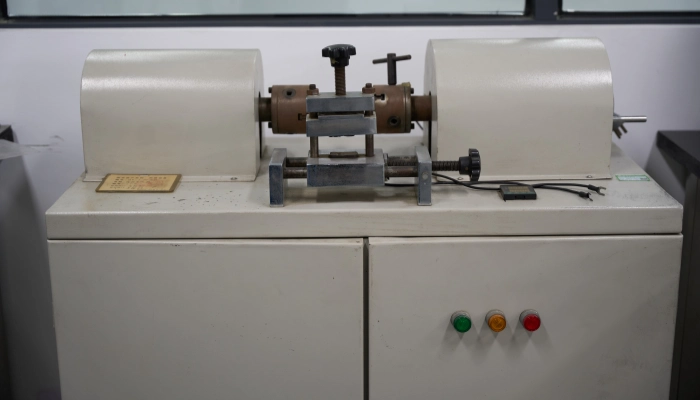

Testing and Certification

Bare Cable Test Report

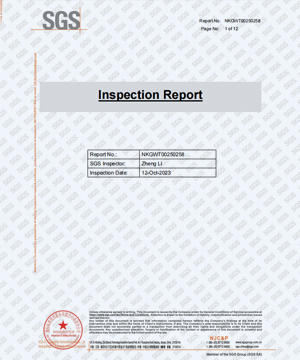

SGS Inspection Report

Certificate of Acceptance

ISO Quality Certificate

ISO Environmental Certificate

ISO Occupational Certificate

UL Laboratory Certificate

UL Product Certificate

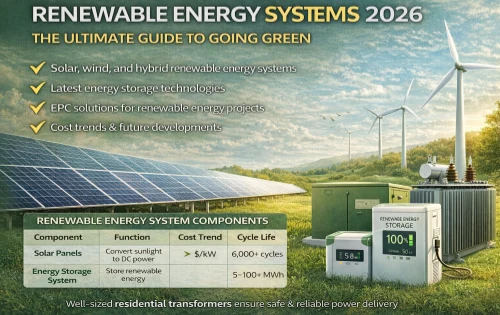

Project Cases

Peru Solar PV Project

CompletedNPC Electric Delivers Medium-Voltage Cables for Peru Solar PV Project

Country:Peru

Model:HEPRZ1(AS) 1x630 mm² 19/33kV x 6km

Chile El Project

CompletedReliable 19/33kV MV cables ensuring safe, stable, and efficient power transmission for critical projects.

Country:Chile

Model:19/33kV MV Power Cables x 5km

Dominican Edenorte Project

CompletedProvide outdoor power solutions for urban main road reconstruction projects to adapt to complex environments.

Country:Dominican

Model:NPC AAAC Cable & Triplex Cable x 10km

Related Articles

Technical Advantages

FAQ From Customers

-

What is the meaning of AAAC conductor?

AAAC conductor stands for All Aluminum Alloy Conductor. It is a type of electrical conductor made from aluminum alloy, designed to provide better mechanical strength and corrosion resistance compared to AAC conductors. This allows AAAC conductors to be used in more challenging environments and for longer spans in overhead power lines, especially in areas with high humidity, salinity, or extreme weather conditions. -

What is the difference between AAC, AAAC, and ACSR?

The key differences between AAC, AAAC, and ACSR conductors lie in their construction and material composition.

1. AAC (All Aluminum Conductor) is made entirely of aluminum, ideal for shorter spans.

2. AAAC (All Aluminum Alloy Conductor) uses aluminum alloy, providing better strength and corrosion resistance, making it suitable for longer spans and harsh conditions.

3. ACSR (Aluminum Conductor Steel Reinforced) combines aluminum and steel, offering high tensile strength and is used for long-distance power transmission. ACSR is typically preferred for high-voltage applications, while AAAC and AAC are used for lower voltage systems. -

What is the use of AAAC conductor?

AAAC conductors are primarily used in overhead power lines for medium to long-distance transmission. Due to their high strength and corrosion resistance, AAAC conductors are ideal for use in power distribution networks and in areas with environmental challenges, such as coastal regions, where traditional aluminum conductors might corrode faster. They are also widely used in renewable energy projects, such as solar and wind power farms, where durability and reliability are essential. -

How does AAAC conductor compare to other conductor types?

Compared to AAC (All Aluminum Conductor) and ACSR (Aluminum Conductor Steel Reinforced), AAAC conductor offers superior corrosion resistance and mechanical strength due to the aluminum alloy material. While AAC conductors are lightweight and cost-effective for short-distance power distribution, AAAC conductors excel in areas with higher corrosion risks and are ideal for medium to long-span transmission lines. ACSR, with its steel core, is better suited for high-tension, long-distance high voltage transmission lines. -

What are the advantages of using AAAC conductors for power transmission?

The main advantages of using AAAC conductors in power transmission are their strength, corrosion resistance, and lighter weight compared to traditional aluminum conductors. The aluminum alloy composition makes them ideal for areas with harsh environmental conditions, such as coastal or high-humidity regions, where corrosion is a concern. Additionally, AAAC conductors allow for longer spans between transmission poles, reducing installation costs and improving overall network efficiency.