What Is Bare Conductor Cable? Uses, Types, and Benefits Explained

Bare conductor cables, which are high-purity copper or aluminum metal wires without insulation, are the basis of overhead power lines. This article will systematically explain its definition and characteristics, focusing on its application in power transmission, current mainstream types, and core advantages.

Whether you're a beginner in the field of electrical engineering or just curious about power infrastructure, this guide will help you understand the basics of bare copper conductors, wires and cables.

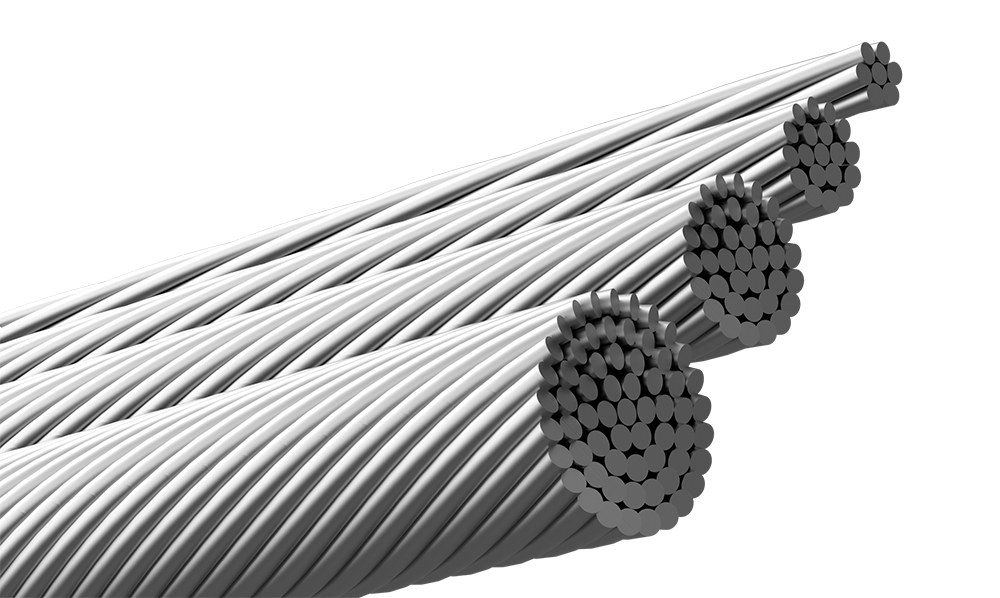

What Is a Bare Conductor Cable?

A bare conductor cable is an electrical conductor that does not have any form of insulation or protective covering. Unlike regular power cables that are jacketed to prevent contact with the environment or other conductors, bare conductors are exposed.

These cables are typically made from bare copper wire or aluminum and are often drawn copper, meaning the metal has been pulled through dies to achieve a specific diameter and tensile strength.

Due to their lack of insulation, bare conductors are mainly used in open-air environments, such as overhead transmission and distribution lines.

Why Use Bare Conductors?

Bare conductors are chosen for several reasons:

High Conductivity: Especially when made from drawn copper, bare conductors offer excellent electrical conductivity, making them ideal for power transmission.

Cost-Effective: Without insulation materials, these cables are cheaper to produce and maintain.

Lightweight: Particularly in aluminum-based conductors, which are easier to string over long distances.

Ease of Installation: Bare cables are easier to work with in overhead line configurations.

Common Applications of Bare Conductor Cables

Bare conductors are widely used in both urban and rural settings for:

Overhead Power Transmission Lines

Substation Busbars

Grounding Systems

Earthing Applications

Trolley Lines and Railways

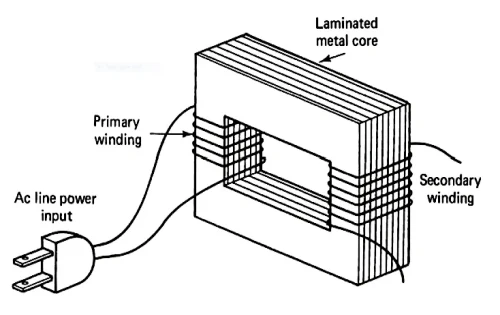

Transformer Connections

They are especially suitable for use in overhead lines where insulation is not necessary because of air clearance and spacing standards.

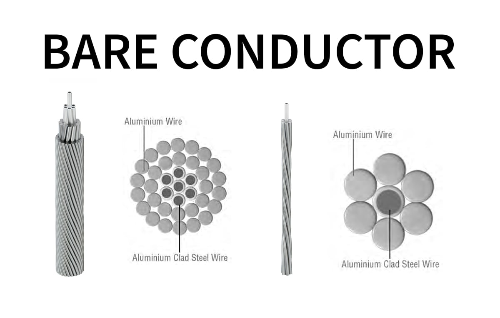

Types of Bare Conductor

There are several types of bare conductor wires and cables, each designed for specific applications. The most commonly used types include:

1. Bare Copper Wire

Made from drawn copper, this is the most conductive and corrosion-resistant option. It is used in grounding, earthing, and bonding applications.

2. AAAC (All-Aluminum Alloy Conductor)

These are made of aluminum alloy, offering a high strength-to-weight ratio and corrosion resistance, suitable for coastal or industrial areas.

3. ACSR (Aluminum Conductor Steel Reinforced)

Combining aluminum's conductivity with steel's tensile strength, ACSR is ideal for long-distance high-voltage overhead lines.

4. AAC (All-Aluminum Conductor)

Known for its excellent conductivity and low weight, AAC is commonly used in urban power distribution.

5. ACAR (Aluminum Conductor Alloy Reinforced)

This type balances conductivity and strength, used in areas requiring better mechanical performance than AAC but not as much as ACSR.

Materials Used in Bare Conductors

The performance of bare conductors largely depends on the materials used:

Copper: Offers the highest electrical conductivity (over 100% IACS) and is highly corrosion-resistant.

Aluminum: Lighter and more economical, though less conductive than copper.

Steel: Used as reinforcement, especially in ACSR conductors, to improve tensile strength.

Advantages of Bare Copper Conductors

Bare copper conductors have several benefits:

High Conductivity: Ideal for minimizing power loss.

Corrosion Resistance: Copper is naturally resistant to oxidation and environmental damage.

Mechanical Flexibility: Easy to bend, shape, and install.

Thermal Performance: Can withstand high temperatures without degradation.

Longevity: Copper conductors often last decades without failure.

Installation Considerations

When installing bare conductor cables, it's important to consider:

Clearance and Spacing: To prevent arcing or short circuits.

Environmental Conditions: Corrosive or coastal environments may require specific alloys.

Mechanical Load: Wind, ice, and weight require conductors with adequate tensile strength.

Frequently Asked Questions (FAQ)

Q1: Are bare conductors safe to use without insulation?

A1: Yes, when used in overhead or well-spaced environments where physical contact is unlikely, bare conductors are safe and commonly used.

Q2: What is the difference between bare copper wire and tinned copper wire?

A2: Bare copper wire is untreated, while tinned copper wire is coated with a layer of tin to enhance corrosion resistance in moist or marine environments.

Q3: Can bare conductors be used underground?

A3: Typically, no. Underground installations require insulated cables to prevent contact with soil, moisture, and other conductors.

Q4: Why is drawn copper preferred in bare conductors?

A4: Drawn copper improves mechanical strength and provides uniform diameter and surface finish, enhancing conductivity and performance.

Q5: What’s the most commonly used bare conductor type for transmission lines?

A5: ACSR (Aluminum Conductor Steel Reinforced) is widely used due to its excellent strength and conductivity over long distances.

In conclusion, bare conductor cables—especially those made from bare copper wire and drawn copper—are essential for efficient and cost-effective overhead line power transmission. Understanding the types of bare conductor, their materials, and key benefits helps ensure proper selection for specific infrastructure projects.

Whether you're designing a substation or installing transmission lines, selecting the right bare copper conductors, wires, and cables is critical to system performance and safety.