Understanding Transformer Cooling Systems: Oil-Cooled vs. Air-Cooled Solutions

During operation, transformers generate significant heat in their cores and coils due to copper losses (I²R) and iron losses. To maintain transformer performance and prevent insulation breakdown, an effective transformer cooling system is required to ensure efficient voltage conversion and stable power distribution.

What is the Cooling System of a Transformer?

A transformer cooling system is designed to dissipate the heat generated during operation, keeping the winding temperature within safe limits. Without adequate cooling, overheating can shorten transformer life, degrade insulation, and increase the risk of failure.

The choice of cooling method depends on transformer type, rating, installation environment, and operational requirements. Common transformer cooling methods include:

- Natural Air (AN) – used in small dry-type transformers, where heat is dissipated directly into the surrounding air.

- Forced Air (AF) – fans provide additional airflow for larger dry-type units.

- Oil-Immersed Cooling – using mineral oil or synthetic ester as the cooling medium, suitable for medium to large power transformers.

- Water-Cooled Systems – applied in high-capacity units where oil-to-water heat exchangers are required.

Transformer Cooling Classes

Transformers are categorized into cooling classes defined by IEC and IEEE standards. Each designation specifies how heat is transferred from windings to the environment.

- AN / AF (Air Natural / Air Forced): Used for dry type transformers. Cooling relies on natural or forced air circulation.

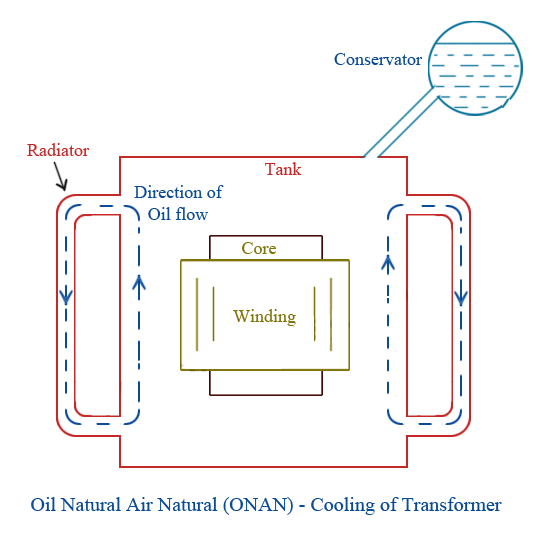

- ONAN (Oil Natural Air Natural): Transformer oil circulates naturally, and heat is dissipated into the surrounding air.

- ONAF (Oil Natural Air Forced): Oil circulation remains natural, but fans force air over radiators.

- OFAF (Oil Forced Air Forced): Oil is pumped through radiators while fans accelerate air cooling.

- ODAF / OFWF (Oil Directed Air Forced / Oil Forced Water Forced): Advanced cooling for very large power transformers, combining forced oil flow with air or water cooling.

|

Cooling Method |

Cooling Medium |

Circulation Type |

Typical Application |

Advantages |

Limitations |

|

Air Natural (AN) |

Air |

Natural convection |

Small dry type transformers |

Simple, maintenance-free, safe |

Limited capacity, less efficient |

|

Air Forced (AF) |

Air |

Fans (forced air flow) |

Medium dry type transformers |

Better cooling than AN, compact |

Requires fans and maintenance |

|

Oil Natural Air Natural (ONAN) |

Mineral oil + Air |

Natural oil flow, natural air convection |

Distribution transformers up to 20–30 MVA |

Reliable, widely used, self-regulated |

Cooling capacity limited for larger units |

|

Oil Natural Air Forced (ONAF) |

Mineral oil + Air |

Natural oil flow, forced air with fans |

Medium power transformers (30–100 MVA) |

Increased load capacity, flexible |

Requires fan system, higher O&M cost |

|

Oil Forced Air Forced (OFAF) |

Mineral oil + Air |

Oil pumps + fans |

Large power transformers |

High cooling efficiency, supports overload |

Complex system, more maintenance |

|

Oil Directed Air Forced (ODAF) |

Mineral oil + Air |

Directed oil flow + fans |

Extra-large transformers |

Ensures uniform cooling of windings |

Higher cost, complex design |

|

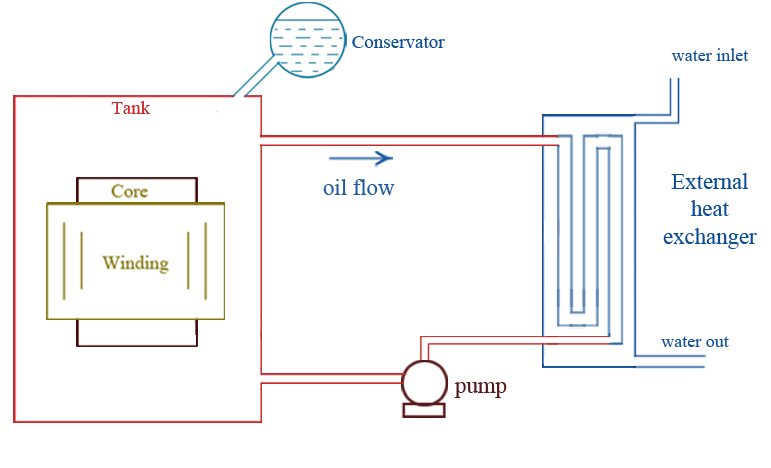

Oil Forced Water Forced (OFWF) |

Mineral oil + Water |

Oil pumps + water circulation |

Very large transformers in power plants |

Very high cooling capacity, compact |

Requires continuous water supply, corrosion risk |

These classifications balance efficiency, cost, and reliability depending on transformer rating and site conditions.

Transformer Oil Cooling System

In an oil-immersed transformer, the windings and core are submerged in insulating oil. The oil acts as both an insulator and a cooling medium.

Working Principle

- Heat generated in the core and coils is transferred to the oil.

- Hot oil rises and circulates naturally or with pumps.

- Heat is released to the environment through radiators or heat exchangers.

Advantages

- High cooling efficiency, suitable for large power transformers.

- Oil improves dielectric strength, extending transformer life.

- Flexible: can integrate natural air, forced air, or water-cooled systems.

Limitations

- Requires periodic oil testing and maintenance.

- Risk of leakage or fire if not properly managed.

Transformer Air Cooling System

Dry type transformers use air cooling as the primary method. Cooling is achieved by direct heat transfer from windings to the surrounding air.

Types of Air Cooling

- Natural Air Cooling (AN): Relies on natural convection; simple and maintenance-free.

- Forced Air Cooling (AF): Fans blow air across windings to enhance cooling.

Advantages

- No oil, reducing fire risk and environmental concerns.

- Lower maintenance compared to oil-filled units.

- Suitable for indoor, commercial, or environmentally sensitive installations.

Limitations

- Less efficient than oil cooling for high-capacity transformers.

- Sensitive to dust and humidity in industrial environments.

Water-Cooled Transformer Cooling System

For very large transformers, water-cooled systems are used. Heat is transferred from oil to water through heat exchangers.

- Advantages: High cooling capacity, compact design, effective in hot climates.

- Disadvantages: Requires a reliable water supply and strict maintenance to prevent corrosion and leakage.

Choosing the Right Transformer Cooling Method

When selecting a transformer cooling system, engineers must consider:

- Transformer rating: Larger units typically require oil cooling or forced cooling methods.

- Installation site: Indoor installations may prefer dry-type transformers with air cooling.

- Safety and environment: Oil-cooled units require fire protection and monitoring; air-cooled or water-cooled units may be safer in certain environments.

- Operational efficiency: Forced cooling systems (fans, pumps) improve load capacity but increase operational costs.

Practical Applications

- Distribution Transformers (≤2500 kVA): Often use oil natural air natural (ONAN) or dry type with natural air cooling.

- Medium Power Transformers (10–100 MVA): Commonly adopt ONAF or OFAF for improved load handling.

- Large Power Transformers (>100 MVA): Require forced oil systems combined with air or water cooling for continuous reliability.

The cooling system of a transformer plays a critical role in maintaining efficiency, extending service life, and ensuring safe operation. Both oil-cooled and air-cooled transformer systems have unique advantages:

- Transformer oil cooling systems dominate in high-capacity and outdoor power applications.

- Transformer air cooling systems excel in indoor, environmentally sensitive, and safety-critical locations.

Understanding different transformer cooling classes and cooling methods enables engineers to make informed choices for reliable and efficient power infrastructure.